Industry Revolution: How 28-Roll Machines Achieve Perfect Hex Bar Straightening Through Adaptive Technology

In precision metalworking, the ability to handle diverse material specifications separates adequate equipment from exceptional systems. At the forefront of this capability stands the 28-Roll Profile Hex Bar Leveling Machine with its groundbreaking Multi-Size Hex Bar Adaptive Straightening technology - a feature that's redefining production flexibility across global manufacturing sectors.

Section 1: The Adaptive Straightening Breakthrough

Traditional straightening machines required costly changeovers and dedicated setups for different hex bar dimensions. The modern solution? Multi-Size Hex Bar Adaptive Straightening technology embedded in advanced Horizontal/Vertical Combined Roller Systems. This innovation allows instantaneous adjustments for:

Diameter variations from 3mm to 200mm

Different corner radii (sharp vs. rounded hex)

Varying material hardness (HRB 50-110)

"Where we previously needed five separate machines, our 28-Roll Profile Hex Bar Leveling Machine with Multi-Size Hex Bar Adaptive Straightening now handles 98% of our product range," states David Müller, Production Director at EuroTech Metals. "The changeover between sizes takes under 90 seconds."

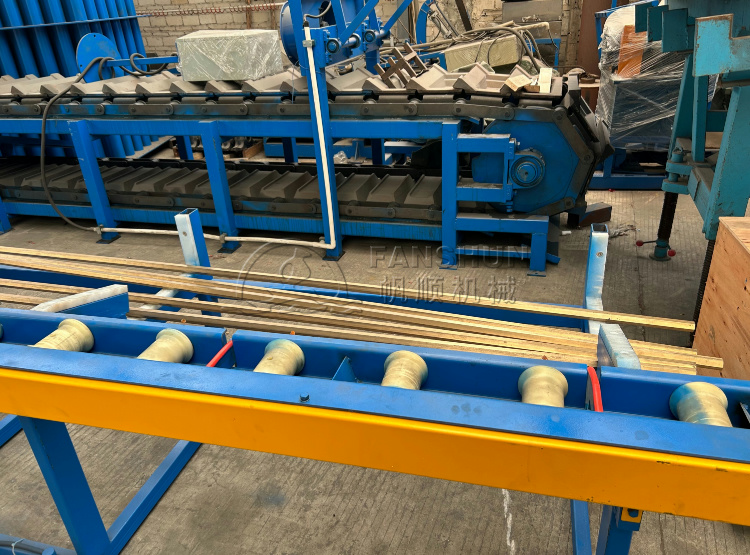

Section 2: Inside the 28-Roll Revolution

At the heart of these systems lies their unparalleled flexibility. The Multi-Size Hex Bar Adaptive Straightening capability allows a single 28-Roll Profile Hex Bar Leveling Machine to handle:

Standard hex bars from 5mm to 150mm

Flats and special profiles

Various alloys including carbon steel, stainless, and titanium

What makes this possible? The secret lies in three key innovations:

Smart Roller Configuration: The Horizontal/Vertical Combined Roller System uses alternating pressure points to eliminate residual stresses

Dynamic Adjustment: Real-time monitoring systems automatically compensate for material springback

Modular Design: Quick-change roller assemblies enable rapid profile switching

Section 3: Automation Integration

No discussion of modern straightening would be complete without examining the Automatic Feeding Hex Bar Straightening Line. These complete systems represent the pinnacle of manufacturing efficiency:

Integrated laser measurement verifies straightness every 0.5 meters

AI-powered quality control automatically rejects substandard material

Automated bundling and packaging systems

"We've achieved a 92% reduction in manual handling with our Automatic Feeding Hex Bar Straightening Line," reports James Koh, Production Manager at Superior Steel Products. "What used to require three operators now needs just occasional monitoring."

Section 4: Custom Solutions for Specialized Needs

For manufacturers with unique requirements, partnering with the right Custom Hex Bar Straightening Machine Manufacturer makes all the difference. Leading providers now offer:

Application-specific roller geometries

Specialized surface treatments to prevent marking

Hybrid systems combining straightening with secondary operations

"Every Custom Hex Bar Straightening Machine Manufacturer worth their salt will conduct extensive material testing before finalizing a design," advises Michael Chen of Allied Metalworks. "We typically run 500-1000 test bars to perfect the settings for a new application."

Section 5: The Numbers That Matter

Precision straightening comes down to key parameters:

| Parameter | Standard Range | High-Precision Target |

|---|---|---|

| Straightness Tolerance | ±0.15mm/m | ±0.05mm/m |

| Speed | 10-20m/min | 5-15m/min (precision) |

| Repeatability | ±0.1mm | ±0.02mm |

| Roller Life | 6-12 months | 18-24 months |

Achieving these numbers requires perfect synchronization between the 28-Roll Profile Hex Bar Leveling Machine's mechanical systems and its computerized controls.

Section 6: Real-World Applications

The impact of these machines spans industries:

Automotive:

Axle components

Suspension parts

Fastener stock

Construction:

Anchor bolts

Structural elements

Reinforcing bars

Energy:

Drill string components

Valve stems

Turbine fasteners

In each case, the Horizontal/Vertical Combined Roller System provides distinct advantages over conventional approaches.

Section 7: The Future of Straightening

Emerging trends suggest:

Smarter Systems: Integration with Industry 4.0 platforms

Greener Operations: Energy recovery systems

Advanced Materials: Solutions for high-strength alloys

"The next generation of 28-Roll Profile Hex Bar Leveling Machine will likely incorporate machine learning to predict and prevent defects before they occur," speculates Dr. Rodriguez.

Section 8: Buyer's Guide

When evaluating systems, consider:

Throughput Requirements: Match machine capacity to production needs

Material Variety: Ensure Multi-Size Hex Bar Adaptive Straightening capability

Future Expansion: Look for modular Automatic Feeding Hex Bar Straightening Line components

Support Network: Choose a Custom Hex Bar Straightening Machine Manufacturer with local service

Conclusion

The modern 28-Roll Profile Hex Bar Leveling Machine represents a significant leap forward in metal processing technology. By combining the precision of Horizontal/Vertical Combined Roller Systems with the flexibility of Multi-Size Hex Bar Adaptive Straightening and the efficiency of Automatic Feeding Hex Bar Straightening Lines, manufacturers can achieve unprecedented quality levels. As demand grows for perfect straightness in critical applications, partnering with an experienced Custom Hex Bar Straightening Machine Manufacturer becomes increasingly vital for maintaining competitive advantage.