Can a Combined Wire Drawing Machine Really Increase Drawing Efficiency by More Than 30%?

In recent years, the wire and cable manufacturing industry has been actively discussing one central question: Can a Combined Drawing Machine really increase drawing efficiency by more than 30%? As global competition intensifies and manufacturing costs continue to rise, manufacturers are searching for solutions that go beyond incremental improvements. The Combined Drawing Machine has emerged as a core topic in this discussion, often mentioned alongside the Integrated Drawing Machine, Joint Drawing Machine, Multi-Function Wire Drawing Machine, and Compound Drawing Machine as part of a new generation of advanced wire drawing equipment.

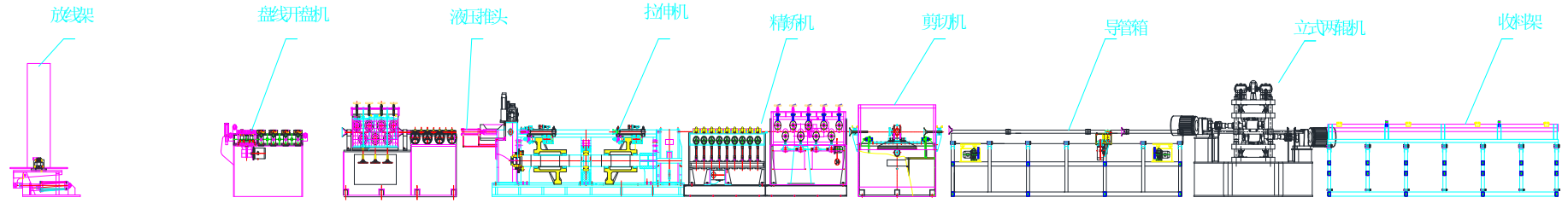

The Combined Drawing Machine is designed to integrate multiple drawing processes into a single, continuous system. Unlike traditional standalone equipment, a Combined Drawing Machine reduces material handling, minimizes downtime, and ensures process stability. When compared to conventional solutions, manufacturers report that a Combined Drawing Machine can significantly streamline production workflows. This efficiency gain is one of the main reasons why the Combined Drawing Machine is increasingly replacing older systems.

From a technical perspective, the Integrated Drawing Machine represents a major leap forward. An Integrated Drawing Machine consolidates multiple drawing stages, annealing units, and lubrication systems into one coordinated platform. This level of integration allows the Integrated Drawing Machine to maintain consistent tension control and speed synchronization. As a result, the Integrated Drawing Machine delivers smoother operation and higher throughput, which directly contributes to efficiency improvements exceeding 30% in many production lines.

The Joint Drawing Machine further enhances this advantage by connecting multiple drawing modules into a unified mechanical and control architecture. A Joint Drawing Machine eliminates the inefficiencies associated with transferring wire between separate machines. By using a Joint Drawing Machine, manufacturers can achieve continuous production without frequent stops, which significantly boosts output. In many cases, a Joint Drawing Machine not only improves efficiency but also enhances product consistency and surface quality.

Another key contributor to efficiency gains is the Multi-Function Wire Drawing Machine. A Multi-Function Wire Drawing Machine is capable of handling different wire materials, diameters, and process requirements within a single setup. This versatility allows manufacturers to switch production tasks quickly without extensive reconfiguration. When a Multi-Function Wire Drawing Machine replaces several specialized machines, the reduction in setup time alone can lead to efficiency increases well beyond 30%.

The Compound Drawing Machine is often mentioned as a strategic investment for large-scale production facilities. A Compound Drawing Machine combines mechanical drawing, process control, and automation into a compact footprint. By optimizing space utilization and energy consumption, a Compound Drawing Machine supports higher line speeds while maintaining precision. Many industry reports indicate that a Compound Drawing Machine enables factories to achieve sustained high efficiency over long production cycles.

When examining real-world applications, the Combined Drawing Machine consistently demonstrates measurable performance improvements. Plants that previously relied on fragmented equipment setups report smoother workflows after upgrading to a Combined Drawing Machine. The Integrated Drawing Machine ensures that all subsystems work in harmony, while the Joint Drawing Machine maintains continuous material flow. Together, these features form the backbone of modern wire drawing solutions.

In addition, the Multi-Function Wire Drawing Machine plays a critical role in reducing labor dependency. By automating multiple tasks, a Multi-Function Wire Drawing Machine allows fewer operators to manage more complex processes. This labor efficiency, combined with the technical advantages of the Compound Drawing Machine, contributes to overall productivity gains that often exceed initial expectations.

Energy efficiency is another factor that supports the claim of a 30% improvement. A Combined Drawing Machine typically consumes less energy per unit of output due to optimized motor control and reduced friction losses. Similarly, an Integrated Drawing Machine minimizes energy waste by synchronizing all drawing stages. The Joint Drawing Machine ensures stable operation, while the Multi-Function Wire Drawing Machine adapts energy usage to specific production needs. Meanwhile, the Compound Drawing Machine integrates intelligent monitoring systems to further optimize performance.

Quality improvements should not be overlooked. A Combined Drawing Machine provides better tension control, which reduces wire breakage. The Integrated Drawing Machine ensures consistent annealing and lubrication, while the Joint Drawing Machine maintains uniform drawing conditions. A Multi-Function Wire Drawing Machine supports precise parameter adjustments, and a Compound Drawing Machine guarantees stable long-term operation. Together, these advantages translate into higher yields and less rework.

Industry experts agree that the Combined Drawing Machine is not merely a trend but a structural upgrade. As manufacturing moves toward automation and digitalization, the Integrated Drawing Machine and Joint Drawing Machine are becoming standard configurations. The Multi-Function Wire Drawing Machine addresses the demand for flexibility, while the Compound Drawing Machine meets the need for scalability and efficiency.

So, can a Combined Drawing Machine really increase drawing efficiency by more than 30%? Based on extensive industry data and real production results, the answer is increasingly clear. When properly implemented, a Combined Drawing Machine—supported by an Integrated Drawing Machine architecture, a Joint Drawing Machine layout, a Multi-Function Wire Drawing Machine design, and a Compound Drawing Machine system—can consistently deliver efficiency gains that exceed 30%.

As more manufacturers adopt these advanced solutions, the Combined Drawing Machine is expected to redefine industry benchmarks. The Integrated Drawing Machine will continue to evolve with smarter controls, the Joint Drawing Machine will further reduce process interruptions, the Multi-Function Wire Drawing Machine will expand application ranges, and the Compound Drawing Machine will push productivity to new heights. Together, these technologies confirm that a 30% efficiency improvement is not only possible, but increasingly achievable.