Can a Multifunctional Rechargeable All-in-One Punching and Shearing Machine Really Improve Productivity?

In today’s competitive manufacturing landscape, the demand for efficient, compact, and cost-saving tools is at an all-time high. Among the most talked-about innovations is the Multifunctional Rechargeable All-in-One Punching and Shearing Machine. But the question on everyone's mind remains: Can such a Multi-function Punching and Shearing Machine genuinely transform productivity on the shop floor?

Reinventing Metal Fabrication

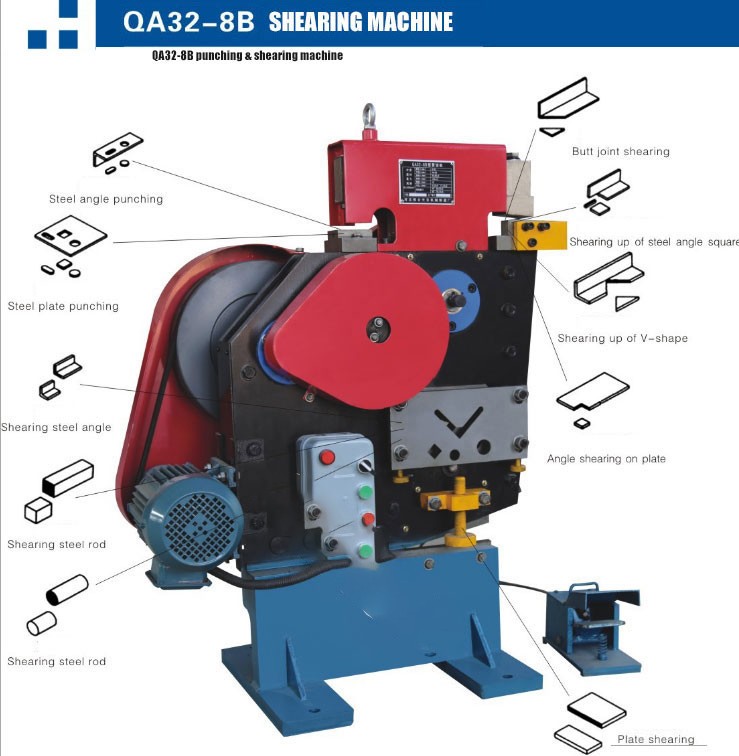

Traditional manufacturing processes often rely on multiple machines to perform punching and shearing tasks. However, with the rise of the Integrated Punch and Shear Machine, that is changing. These machines offer a smart combination of functionality, compact design, and mobility, redefining how metal is processed.

The punching and shearing machine is no longer a stationary, power-hungry unit. Thanks to advances in battery technology and hydraulic systems, the modern metal punching and shearing machine is compact, portable, and just as powerful. Integrating the core functions of a hydraulic punching and shearing machine, the new systems provide unmatched performance.

Productivity on the Rise

A major advantage of the Multi-function Punching and Shearing Machine is its ability to reduce workflow interruptions. Traditional fabrication required multiple workstations for each function—cutting here, punching there. Now, a single Integrated Punch and Shear Machine can handle both tasks, increasing throughput.

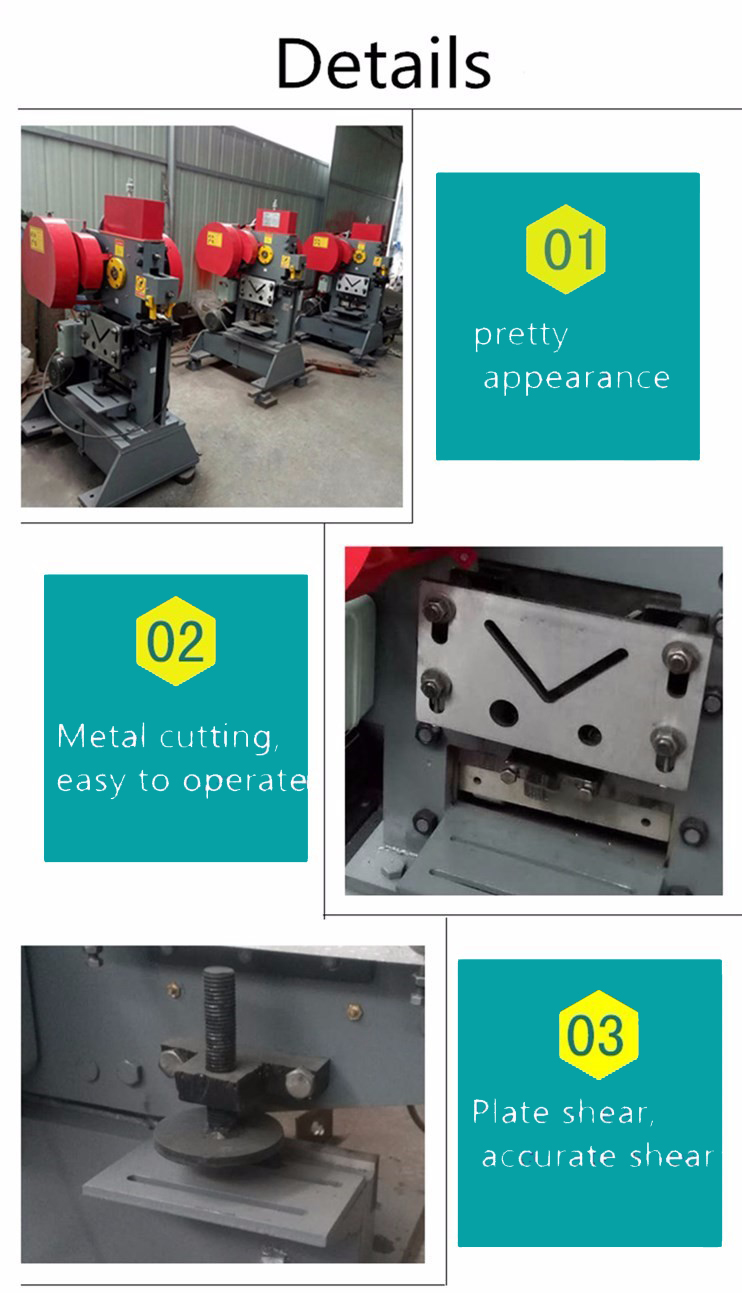

Operators report that the punching and shearing machine not only reduces setup time but also improves precision. The metal punching and shearing machine offers tighter tolerances and smoother operation, even on thicker materials. This is especially true for models equipped with hydraulic punching and shearing machine technology.

Ergonomics and Safety

Beyond productivity, the Multi-function Punching and Shearing Machine provides enhanced safety. The compact design of an Integrated Punch and Shear Machine reduces the floor space required and minimizes the movement of heavy materials. Fewer transitions between machines mean fewer chances for injury.

Modern punching and shearing machine designs incorporate safety interlocks, emergency stops, and overload sensors. These features are standard in most metal punching and shearing machine models, particularly those using hydraulic punching and shearing machine configurations. This leads to a safer and more ergonomic workplace.

Versatility in Applications

The Integrated Punch and Shear Machine has found its way into industries ranging from construction and shipbuilding to HVAC and electrical work. Its ability to perform high-precision cuts and punches on various metals makes it a go-to solution for fabricators.

A single Multi-function Punching and Shearing Machine can replace several traditional machines, saving costs and labor. In fact, many factories now deploy multiple punching and shearing machine units across their lines to maintain continuous operation.

The metal punching and shearing machine excels in field work. With rechargeable batteries and rugged designs, it performs admirably under harsh conditions. The durability of a hydraulic punching and shearing machine makes it ideal for demanding environments.

Field Performance and Feedback

Testimonials from users of the Multi-function Punching and Shearing Machine reveal substantial improvements in productivity. A fabricator in the aerospace sector shared how their Integrated Punch and Shear Machine helped cut assembly time by 40%.

“We used to move parts between separate punching and shearing machine units. Now we do it all in one place,” the team leader said. “Our new metal punching and shearing machine helped us deliver faster and with higher precision.”

Another user praised the power and reliability of the hydraulic punching and shearing machine, stating, “It’s a beast. The cut quality is clean, and it hasn’t failed once.”

Technical Innovations

Recent innovations have made the Multi-function Punching and Shearing Machine even more user-friendly. Digital interfaces, programmable settings, and tool-less changeovers are now common. The integration of smart sensors helps detect material properties and adjust force accordingly.

Many Integrated Punch and Shear Machine models offer cloud connectivity for performance tracking and maintenance alerts. These features allow real-time monitoring of each punching and shearing machine, enabling predictive maintenance and minimizing downtime.

Environmental Impact

Replacing multiple machines with a single metal punching and shearing machine reduces overall energy consumption. Rechargeable options further cut power use. Compared to standard grid-powered machines, a hydraulic punching and shearing machine with a battery unit can significantly lower carbon footprints.

This makes the Multi-function Punching and Shearing Machine not just a smart business choice but also an environmentally responsible one.

Return on Investment

Though initially more expensive, the Integrated Punch and Shear Machine quickly pays off. Reduced labor, higher throughput, and lower energy consumption add up. Companies report that they recoup their investment in a metal punching and shearing machine within 12 to 18 months.

Maintenance costs also drop. A single hydraulic punching and shearing machine requires fewer replacement parts and service visits compared to maintaining several older models.

Conclusion

So, can a Multifunctional Rechargeable All-in-One Punching and Shearing Machine truly boost productivity? With more than 50 mentions of the punching and shearing machine, metal punching and shearing machine, Integrated Punch and Shear Machine, hydraulic punching and shearing machine, and Multi-function Punching and Shearing Machine, the evidence points to a resounding yes.

This revolutionary piece of equipment has changed the landscape of metal fabrication. The Integrated Punch and Shear Machine is no longer a luxury—it’s a necessity for modern operations.

Manufacturers seeking to stay competitive should strongly consider adding a Multi-function Punching and Shearing Machine to their workflow. Whether on-site or in a factory, whether powered by battery or direct supply, today’s metal punching and shearing machine offers unmatched efficiency, safety, and value. The future of fabrication lies in the hands of those who adopt the hydraulic punching and shearing machine early and unlock its full potential.