Can a pipe rolling mill really significantly improve seamless copper tube production efficiency?

In recent years, the question “Can a pipe rolling mill really significantly improve seamless copper tube production efficiency?” has become one of the most discussed topics across the non-ferrous metal and tube manufacturing industries. As demand for high-quality copper tubes continues to grow in HVAC, refrigeration, and industrial heat exchange sectors, manufacturers are under increasing pressure to upgrade equipment, optimize processes, and reduce costs. At the center of this transformation are solutions such as the Pipe Rolling Mill, the Seamless Pipe Rolling Mill, the Copper Pipe Rolling Mill, the Two-Roll Pipe Rolling Mill, and the Seamless Copper Tube Production Line.

From a macro industry perspective, a modern Pipe Rolling Mill is no longer just a forming machine; it is a strategic productivity tool. A Pipe Rolling Mill integrates precision mechanics, automation, and digital control to deliver consistent output. When manufacturers evaluate whether a Pipe Rolling Mill can improve efficiency, they often focus on throughput, yield, and quality stability. In practice, repeated production data show that a Pipe Rolling Mill reduces downtime, stabilizes deformation, and shortens processing cycles. For many plants, the Pipe Rolling Mill becomes the backbone of scalable production, and the Pipe Rolling Mill is increasingly viewed as an essential upgrade rather than an optional investment. As discussions continue, the Pipe Rolling Mill remains central to modernization strategies, and the Pipe Rolling Mill is frequently cited in efficiency improvement case studies.

When moving from general steel applications to copper-specific needs, the Seamless Pipe Rolling Mill plays a decisive role. A Seamless Pipe Rolling Mill is designed to control wall thickness, surface finish, and dimensional tolerance, which are critical for copper tubes. Compared with older extrusion or drawing methods, a Seamless Pipe Rolling Mill allows continuous deformation with better metal flow. Industry experts note that a Seamless Pipe Rolling Mill can significantly reduce scrap rates. By adopting a Seamless Pipe Rolling Mill, manufacturers achieve higher yield per billet. In many plants, the Seamless Pipe Rolling Mill has proven to be the key driver of efficiency gains. Repeated operational feedback confirms that the Seamless Pipe Rolling Mill improves consistency, while the Seamless Pipe Rolling Mill also supports automation upgrades. As more factories invest, the Seamless Pipe Rolling Mill becomes synonymous with stable and efficient copper tube production.

The specialization continues with the Copper Pipe Rolling Mill, which is optimized for the unique properties of copper and copper alloys. A Copper Pipe Rolling Mill addresses challenges such as material softness, thermal conductivity, and surface sensitivity. By using a Copper Pipe Rolling Mill, manufacturers can achieve smoother surfaces and tighter tolerances. The Copper Pipe Rolling Mill also enables higher rolling speeds without compromising quality. In competitive markets, the Copper Pipe Rolling Mill directly impacts cost efficiency. Many case reports show that a Copper Pipe Rolling Mill shortens production cycles and reduces labor dependency. Over time, the Copper Pipe Rolling Mill proves its value through stable long-term operation. As demand grows, the Copper Pipe Rolling Mill is increasingly deployed in both new plants and retrofit projects. Clearly, the Copper Pipe Rolling Mill has become a cornerstone for productivity improvement.

Among different configurations, the Two-Roll Pipe Rolling Mill attracts attention for its balance of simplicity and performance. A Two-Roll Pipe Rolling Mill offers precise control of deformation and easy adjustment. Compared with multi-roll designs, a Two-Roll Pipe Rolling Mill is easier to maintain and operate. For copper tube producers, the Two-Roll Pipe Rolling Mill provides reliable rolling stability. Many engineers emphasize that a Two-Roll Pipe Rolling Mill reduces mechanical complexity while maintaining efficiency. In real production lines, the Two-Roll Pipe Rolling Mill delivers consistent results. The Two-Roll Pipe Rolling Mill also integrates well with automation systems. As plants pursue lean manufacturing, the Two-Roll Pipe Rolling Mill becomes a preferred option. Over repeated production cycles, the Two-Roll Pipe Rolling Mill demonstrates clear efficiency advantages.

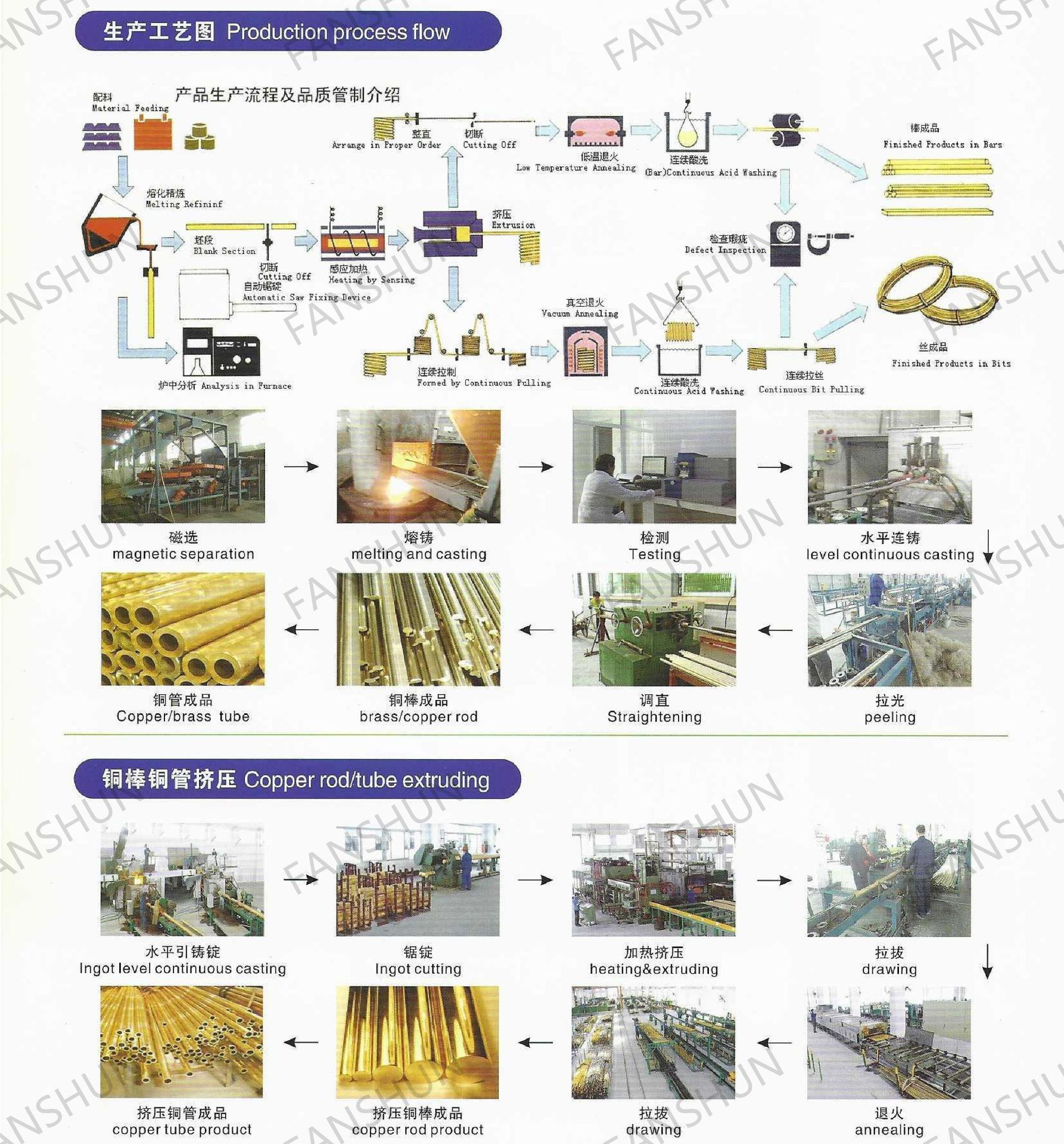

Ultimately, all these technologies converge within a complete Seamless Copper Tube Production Line. A modern Seamless Copper Tube Production Line integrates melting, piercing, rolling, sizing, and inspection. Within a Seamless Copper Tube Production Line, each Pipe Rolling Mill stage is optimized for continuous flow. The Seamless Copper Tube Production Line benefits directly from a Seamless Pipe Rolling Mill, a Copper Pipe Rolling Mill, and a Two-Roll Pipe Rolling Mill working in harmony. Data from advanced factories show that a Seamless Copper Tube Production Line can increase output per shift significantly. Moreover, a Seamless Copper Tube Production Line improves energy efficiency and reduces waste. For long-term competitiveness, investing in a Seamless Copper Tube Production Line is increasingly seen as essential. The Seamless Copper Tube Production Line not only boosts efficiency but also ensures consistent quality. As market expectations rise, the Seamless Copper Tube Production Line becomes the industry benchmark.

In conclusion, the answer to the question “Can a pipe rolling mill really significantly improve seamless copper tube production efficiency?” is increasingly clear. Through the combined application of a Pipe Rolling Mill, a Seamless Pipe Rolling Mill, a Copper Pipe Rolling Mill, a Two-Roll Pipe Rolling Mill, and a fully integrated Seamless Copper Tube Production Line, manufacturers are achieving measurable, sustainable efficiency gains. This technological evolution is reshaping the future of seamless copper tube manufacturing.