Can an Upward Casting Line for Oxygen-Free Copper Rods Really Ensure High Purity?

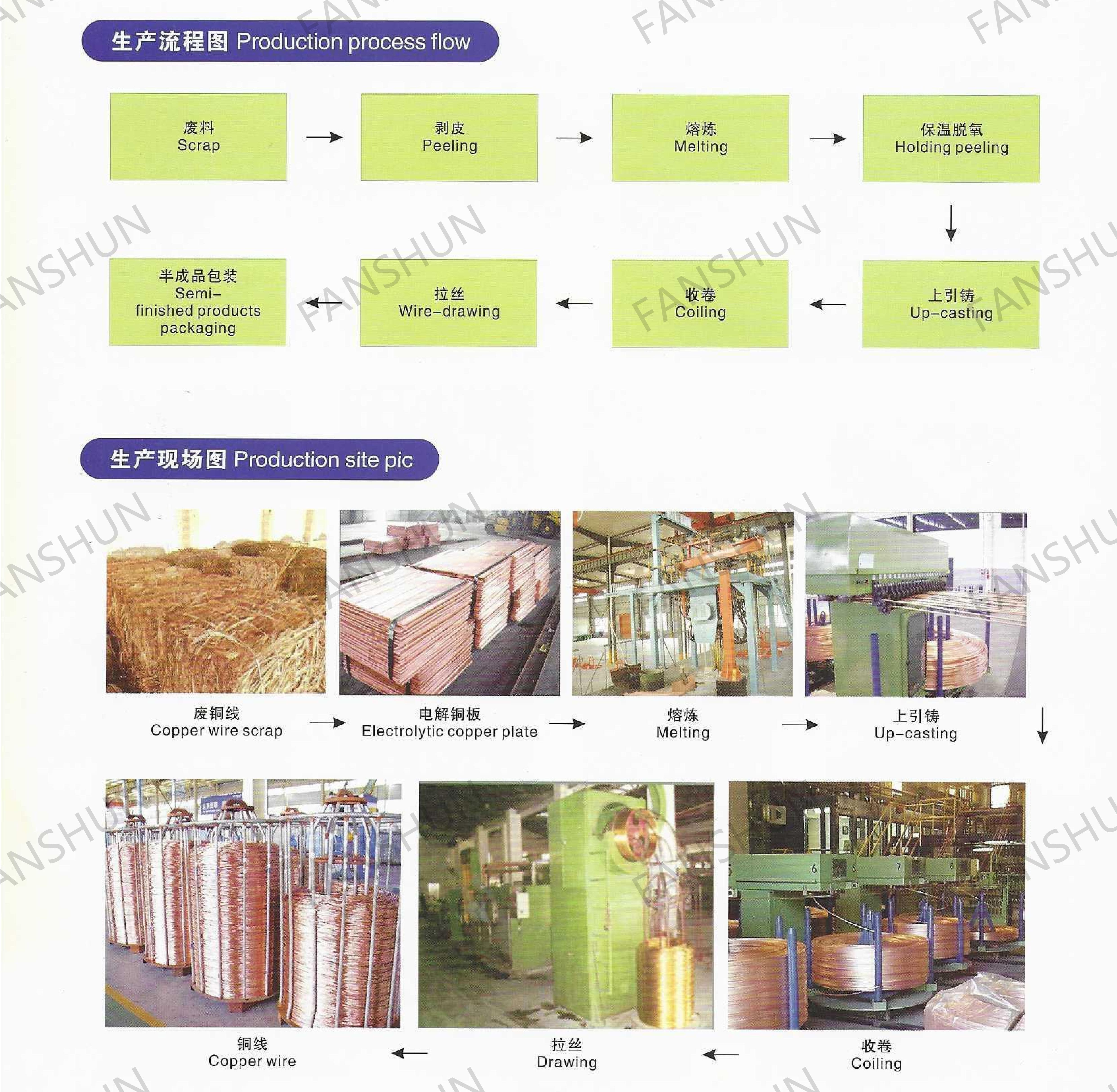

In recent years, global demand for high-conductivity Oxygen free copper rods has increased sharply, especially in the electrical, electronic, and renewable-energy sectors. This growing demand has pushed manufacturers to examine whether modern Oxygen-Free Copper Rod Upcasting technologies—built around the upward casting furnace, Copper rod upward casting equipment, and integrated scrap copper electric furnace systems—can truly deliver the purity levels that industries require. As more producers shift from traditional casting to Oxygen-Free Copper Rod Upcasting, the question becomes increasingly relevant: Can an upward casting line for Oxygen free copper rods really ensure high purity?

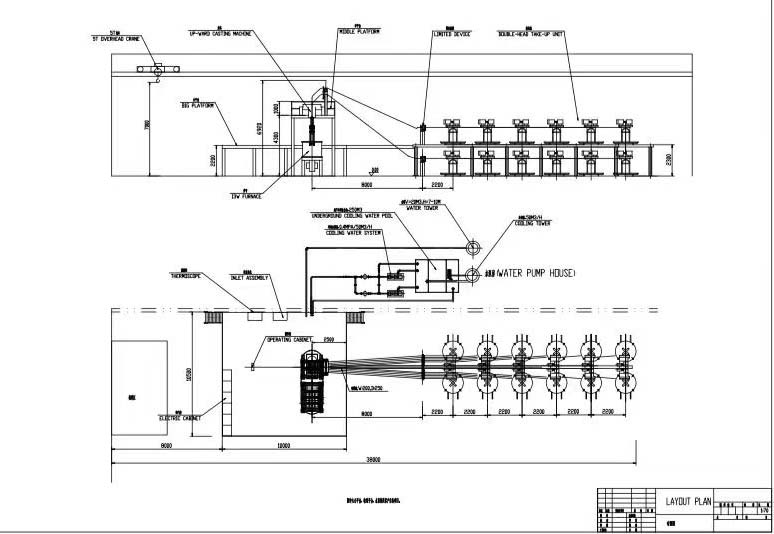

Experts point out that the answer lies in the synergy between the upward casting furnace, Copper rod upward casting equipment, the feeding and refining capabilities of a scrap copper electric furnace, and the controlled atmosphere inherent to Oxygen-Free Copper Rod Upcasting methods. These technologies work together to minimize contamination and oxidation during the casting process. In the core of any modern upcasting facility, the upward casting furnace maintains a stable thermal environment that prevents re-oxidation, allowing Oxygen free copper rods to form with a dense, uniform microstructure.

Manufacturers repeatedly highlight that Oxygen-Free Copper Rod Upcasting lines achieve purity because they melt and refine raw materials, including recycled feedstock, in a scrap copper electric furnace before the molten copper enters the upward casting furnace. The scrap copper electric furnace is engineered to remove unwanted impurities while preparing the copper melt for a smooth transition into the upward casting furnace. This tightly controlled process ensures that Oxygen free copper rods maintain the low oxygen content that high-performance applications require.

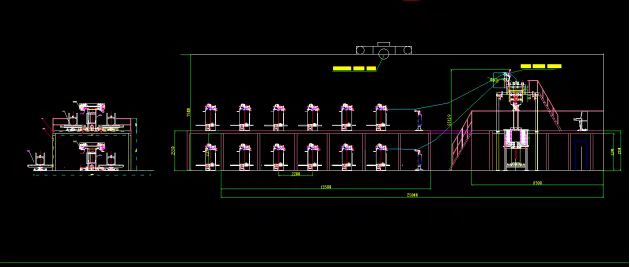

The next critical component is the Copper rod upward casting equipment, which stabilizes the solidification, pulling, and forming stages of Oxygen-Free Copper Rod Upcasting. By combining an upward casting furnace with advanced Copper rod upward casting equipment, producers can continuously form Oxygen free copper rods with exceptional consistency. Unlike older batch-casting methods, Oxygen-Free Copper Rod Upcasting lines maintain constant thermal conditions and eliminate turbulence, which significantly reduces gas entrapment and oxide formation.

Industry analysts note that each time molten copper rises through the controlled crystal-growth zone of an upward casting furnace, it benefits from the oxygen-free atmosphere created by the Oxygen-Free Copper Rod Upcasting process. When paired with a scrap copper electric furnace, which delivers pre-refined molten copper at stable temperatures, the system drastically lowers the likelihood of contamination. This combination has established Copper rod upward casting equipment and Oxygen-Free Copper Rod Upcasting as industry benchmarks for purity.

As market needs evolve, the role of Oxygen free copper rods in high-frequency electronics, EV motors, power grid components, and precision connectors continues to grow. Producers adopting integrated scrap copper electric furnace systems feeding directly into an upward casting furnace are reporting measurable improvements in quality control. With every cycle, Oxygen-Free Copper Rod Upcasting enhances purity by reducing exposure to ambient air, stabilizing the melt column, and strengthening crystal formation. This controlled upward-solidification environment is a key reason why Oxygen free copper rods produced through the process demonstrate exceptional electrical conductivity.

Furthermore, sustainability concerns are driving companies toward recycling-based production. Here again, scrap copper electric furnace technology becomes crucial. It allows recycled materials to be melted, de-oxidized, and refined before entering the upward casting furnace. This makes Oxygen-Free Copper Rod Upcasting not just a high-purity solution but also an environmentally efficient one. The resulting Oxygen free copper rods achieve the same purity as rods made from virgin materials.

Industrial reports show that the reliability of Copper rod upward casting equipment—combined with the thermal stability of the upward casting furnace—is a decisive factor. Continuous casting minimizes turbulence and impurity inclusion, enabling the Oxygen-Free Copper Rod Upcasting process to repeatedly achieve purity levels demanded by modern engineering standards. As more facilities upgrade to integrated lines with a scrap copper electric furnace, the production of Oxygen free copper rods becomes even more predictable and consistent.

In conclusion, the industry consensus is clear: yes, an upward casting line can truly ensure high purity. Through the combined power of the upward casting furnace, Oxygen-Free Copper Rod Upcasting, advanced Copper rod upward casting equipment, and the refining capability of a scrap copper electric furnace, manufacturers can consistently produce world-class Oxygen free copper rods. As global technology advances, these systems will continue to define the standard for purity, performance, and reliability in copper rod manufacturing.