Can Automatic Feeding Machines Handle Different Sizes and Materials?

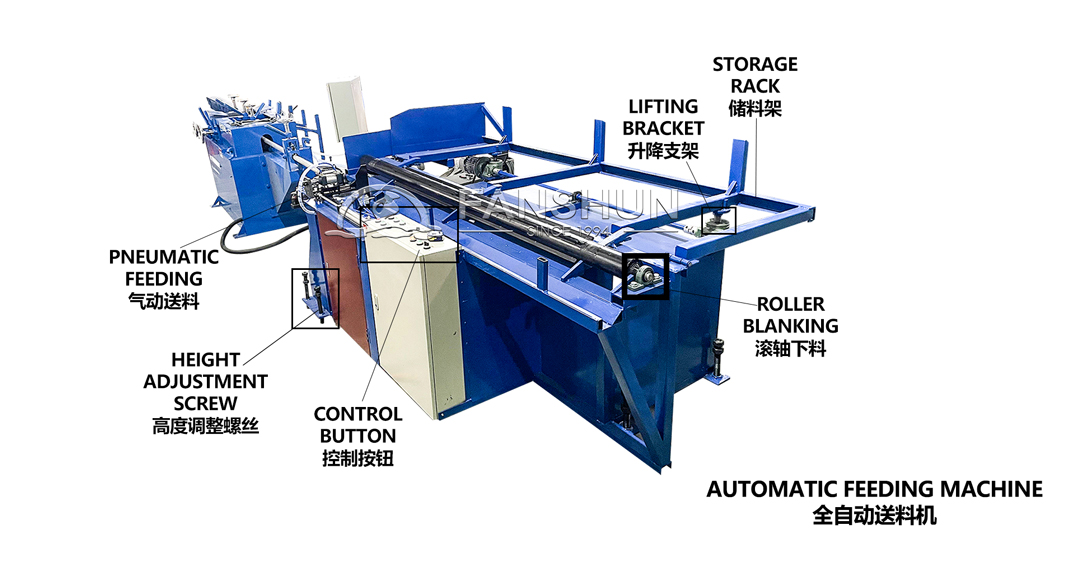

In modern manufacturing, the demand for precision and efficiency has never been higher. One of the most common questions among production managers is: Can automatic feeding machines handle different sizes and materials? The answer lies in the design and flexibility of today’s automated systems. The Automatic Pipe Feeder has become a key component in metalworking, aluminum, and steel industries, offering unmatched versatility in feeding materials of varying sizes.

A pipe feeding machine is capable of handling pipes of different diameters and lengths. Unlike traditional manual methods, the Auto bar feeder automates the entire process, reducing labor costs and improving consistency. When integrated into a production line, an Automatic feeder can feed various materials without stopping for adjustments, ensuring uninterrupted workflow. A Fully Automatic Pipe Feeder further enhances productivity by allowing for quick changeovers between materials of different thicknesses and diameters.

The Automatic Pipe Feeder excels in feeding pipes with precision. Modern pipe feeding machines can adjust clamping pressure, feeding speed, and alignment automatically. This makes the Auto bar feeder a preferred choice for manufacturers who require accuracy and speed. Additionally, the Automatic feeder minimizes human error, ensuring that every pipe and bar is fed consistently into CNC machines.

When dealing with multiple material types, the Fully Automatic Pipe Feeder demonstrates its value. From stainless steel to aluminum, this system can feed pipes and bars of varying properties. The pipe feeding machine can be programmed to adjust speed and handling for each material, while the Automatic Pipe Feeder ensures continuous operation. The Auto bar feeder can even accommodate non-standard sizes, which is critical for custom manufacturing.

Production efficiency is dramatically improved with an Automatic feeder. By integrating a pipe feeding machine or an Automatic Pipe Feeder, operators can maintain high throughput without constant manual intervention. The Auto bar feeder reduces downtime and enables the processing of multiple materials in sequence. Moreover, a Fully Automatic Pipe Feeder allows factories to run multiple shifts with minimal supervision, increasing overall output.

Safety is another important consideration. A pipe feeding machine reduces the need for manual handling of heavy pipes. The Automatic Pipe Feeder includes sensors and emergency stop functions to protect operators. Similarly, the Auto bar feeder and Automatic feeder are designed with enclosed mechanisms to prevent accidents, making them safer alternatives to manual feeding.

Maintenance and durability are key advantages of modern feeding systems. The Auto bar feeder and Fully Automatic Pipe Feeder are built with robust components to handle frequent operation and different materials. Regular maintenance ensures that the Automatic feeder continues to operate efficiently, while the pipe feeding machine remains reliable over time. Using a high-quality Automatic Pipe Feeder can save costs in the long run by minimizing downtime and material waste.

Precision feeding is critical in CNC operations. The Auto bar feeder ensures accurate positioning of every bar, while the Automatic feeder maintains consistent speed and alignment. A Fully Automatic Pipe Feeder can feed pipes into machines with minimal deviation, reducing scrap and improving product quality. Similarly, the pipe feeding machine allows for high-precision feeding across multiple materials and sizes. The Automatic Pipe Feeder thus guarantees both efficiency and precision.

Adaptability is another key strength. The pipe feeding machine can interface with lathes, CNC turning centers, and milling machines. The Automatic Pipe Feeder can handle a range of pipe diameters, while the Auto bar feeder adapts to bars of different lengths and materials. The Automatic feeder provides seamless integration with production lines, and a Fully Automatic Pipe Feeder ensures minimal manual intervention even in complex setups.

For manufacturers producing custom parts, the Auto bar feeder and Fully Automatic Pipe Feeder offer unmatched flexibility. Switching between different materials or sizes is quick and easy. A pipe feeding machine can be programmed for batch production, while an Automatic Pipe Feeder ensures smooth transitions between batches. With the Auto bar feeder, operators can feed both standard and special-sized materials without manual adjustments. Likewise, the Automatic feeder handles multiple materials with consistent reliability.

In conclusion, Automatic Pipe Feeders, pipe feeding machines, Auto bar feeders, Fully Automatic Pipe Feeders, and Automatic feeders are highly capable of handling different sizes and materials. Their versatility, precision, and safety make them indispensable in modern manufacturing. Factories using a pipe feeding machine or Automatic Pipe Feeder can process multiple materials efficiently, while the Auto bar feeder and Automatic feeder ensure consistent operation. A Fully Automatic Pipe Feeder enhances productivity, reduces labor costs, and guarantees quality.

With the continued adoption of smart factory technology, pipe feeding machines will become even more intelligent. The Automatic Pipe Feeder, Auto bar feeder, and Automatic feeder will be monitored in real-time, adjusting speed, alignment, and clamping automatically. This integration ensures maximum efficiency, making the Fully Automatic Pipe Feeder an essential part of modern manufacturing. Manufacturers relying on pipe feeding machines can expect higher throughput, reduced errors, and consistent handling of different materials and sizes.