Can Bar and Tube Peeling Machines Really Eliminate Surface Defects? — Industry Users’ Attention Surges

In recent months, the global metals processing industry has been actively discussing one central question: Can bar and tube peeling machines really eliminate surface defects? With demand for higher-precision materials rising rapidly, it is no surprise that equipment such as the Bar Peeling Machine, Tube Peeling Machine, Round Bar Peeling Line, Tube Surface Peeling Equipment, and CNC Bar Peeling Machine has become the focal point of manufacturers, laboratories, and end-users around the world. As market attention surges, these technologies are being evaluated not only for their ability to remove defects but also for their consistency, cost efficiency, and production stability.

Industry analysts point out that the modern Bar Peeling Machine is now designed to handle a wide range of steels and alloys with extremely tight tolerances. Many factories that previously relied on manual grinding or centerless grinding have shifted to automated peeling solutions because the Bar Peeling Machine can remove outer decarburization layers, scratches, cracks, and oxide scales in a single high-precision pass. With every new production challenge, the Bar Peeling Machine continues to be recognized as a dependable solution for companies targeting premium product grades.

At the same time, the Tube Peeling Machine is gaining momentum in tube manufacturing lines that previously struggled with surface inconsistencies. Whether it is cold-drawn tube preparation or the processing of stainless-steel tubes for high-pressure applications, the Tube Peeling Machine offers improved circularity, smoother surfaces, and consistent removal of material imperfections. Many companies now require multiple Tube Peeling Machine units running in parallel to keep up with rising international orders, particularly in the automotive, hydraulic, and heat-exchange sectors.

Complementing these systems, the Round Bar Peeling Line has emerged as a full-process solution. Instead of isolated peeling stations, an integrated Round Bar Peeling Line includes feeding, peeling, straightening, polishing, chamfering, cutting, and inspection functions. This allows the Round Bar Peeling Line to provide end-to-end manufacturing stability, reducing downtime while improving dimensional accuracy. Many users report that adopting a complete Round Bar Peeling Line significantly lowers labor dependence while raising throughput across multiple product sizes. The Round Bar Peeling Line is now considered essential for large-scale suppliers of precision bars.

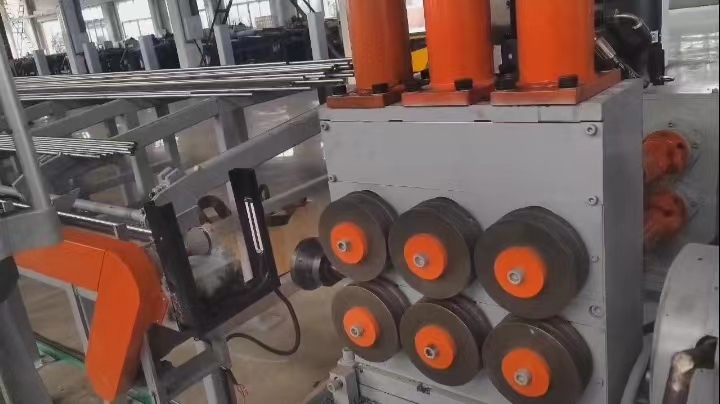

Meanwhile, Tube Surface Peeling Equipment has gained attention for its ability to improve processing speed and uniformity, especially for mid-to-large-diameter tubing where traditional grinding methods are inefficient. Modern Tube Surface Peeling Equipment uses hydraulic stabilization, CNC control systems, and optimized cutting geometries to maximize defect removal while minimizing material wastage. As tube quality requirements continue to rise globally, manufacturers are increasingly upgrading existing lines with advanced Tube Surface Peeling Equipment to stay competitive.

For high-precision applications, especially in aerospace, medical, and energy-sector components, the CNC Bar Peeling Machine is rapidly becoming the preferred choice. Unlike manual or semi-automatic models, the CNC Bar Peeling Machine performs defect removal with controlled cutting depth, real-time adjustment, and automated monitoring. Users praise the CNC Bar Peeling Machine for its improved repeatability and reduced operator intervention. As digital manufacturing becomes the norm, the CNC Bar Peeling Machine stands out as a critical upgrade path for factories targeting high-value markets.

What is particularly noteworthy is how the combined adoption of the Bar Peeling Machine, Tube Peeling Machine, Round Bar Peeling Line, Tube Surface Peeling Equipment, and CNC Bar Peeling Machine is reshaping global production standards. Market surveys indicate that more than half of the firms investing in these technologies experience immediate improvements in product consistency and defect rejection rates. Many of these companies also report that customer complaints about surface flaws drop significantly within months of installing the equipment.

Experts believe that this surge in attention is driven by a broader industrial shift toward automation and traceable quality control. In an increasingly competitive environment, the Bar Peeling Machine and Tube Peeling Machine offer predictable, measurable improvements that directly impact profit margins. Similarly, the expansion of the Round Bar Peeling Line highlights the industry’s desire for integrated solutions rather than isolated machine upgrades. As for advanced digital processing, the CNC Bar Peeling Machine is expected to become standard equipment within the next decade, particularly as precision tolerances move into tighter micrometer ranges.

Looking ahead, analysts forecast sustained growth in demand for Tube Surface Peeling Equipment, especially in markets such as Asia, Eastern Europe, and the Middle East. These regions are experiencing rapid infrastructure expansion, which significantly increases the consumption of high-quality pipes and tubes. As regulatory standards become stricter, industries will rely even more heavily on the performance of Tube Surface Peeling Equipment to stay compliant.

In conclusion, industry evidence strongly suggests that the answer to the question—Can bar and tube peeling machines really eliminate surface defects?—is increasingly “yes.” With the proven capabilities of the Bar Peeling Machine, Tube Peeling Machine, Round Bar Peeling Line, Tube Surface Peeling Equipment, and CNC Bar Peeling Machine, manufacturers worldwide are achieving higher surface quality, increased production efficiency, and greater reliability. As market demand continues to rise, these technologies are positioned to play an even more significant role in shaping the next generation of metal processing standards.