In recent years, the global copper processing industry has been asking a central question: Can Upward Continuous Casting of Copper Strip Achieve Oxygen-Free or Low-Oxygen Production? As downstream sectors such as electronics,renewable energy and high-end manufacturing demand higher performance materials, copper strip products with stricter oxygen control have become a strategic focus. In this context, Upward Continuous Casting Copper Strip technology is increasingly viewed as a key pathway toward producing Oxygen-Free Copper Strip, Low-Oxygen Copper Strip, and High-Purity Copper Strip at industrial scale.

The importance of oxygen control in copper strip production cannot be overstated. Excess oxygen in copper strip may lead to reduced electrical conductivity, hydrogen embrittlement risks, and instability in subsequent rolling and annealing processes. For this reason, manufacturers are investing heavily in technologies that can reliably produce Low-Oxygen Copper Strip and Oxygen-Free Copper Strip while maintaining productivity and cost efficiency. Among these technologies, Upward Continuous Casting Copper Strip stands out due to its unique solidification characteristics.

Compared with traditional horizontal or downward casting, Upward Continuous Casting Copper Strip solidifies against gravity. This allows non-metallic inclusions and residual gases to float away from the solidification front, significantly improving internal quality. As a result, copper strip produced via this method often exhibits a denser microstructure, fewer defects, and more uniform chemical composition. These advantages are critical for the stable production of High-Purity Copper Strip, Low-Oxygen Copper Strip, and Oxygen-Free Copper Strip.

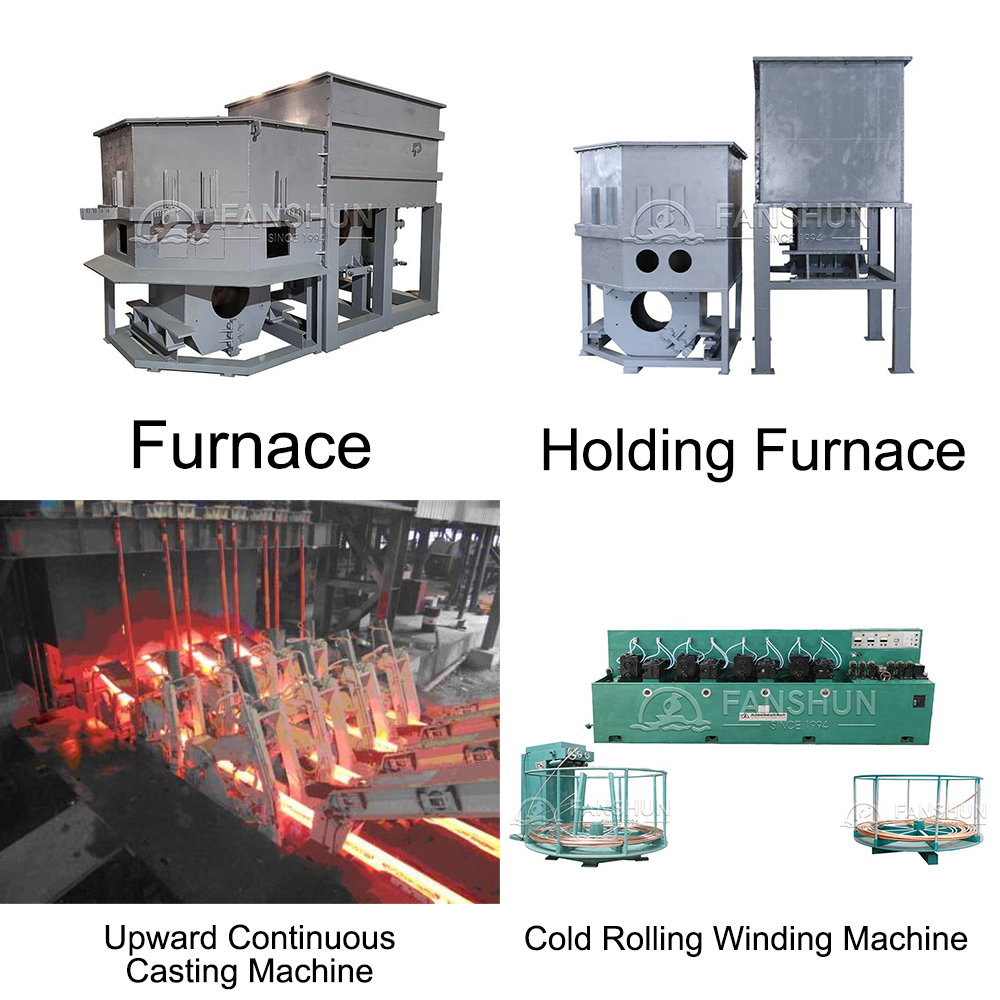

From a process perspective, Upward Continuous Casting Copper Strip integrates melting, refining, and casting in a closed or semi-closed environment. By using high-purity cathode copper, protective atmospheres, and precise temperature control, manufacturers can reduce oxygen pickup during the entire copper strip production process. This is why many industry experts believe that Upward Continuous Casting Copper Strip is inherently well-suited for producing Low-Oxygen Copper Strip and Oxygen-Free Copper Strip.

Market data also supports this trend. Demand for High-Purity Copper Strip continues to grow in applications such as lithium battery current collectors, high-frequency connectors, and semiconductor packaging. In these applications, copper strip purity and oxygen content directly affect performance and reliability. Consequently, suppliers capable of delivering High-Purity Copper Strip, Low-Oxygen Copper Strip, and Oxygen-Free Copper Strip using Upward Continuous Casting Copper Strip gain a significant competitive advantage.

Another critical benefit of Upward Continuous Casting Copper Strip is its compatibility with continuous production. Continuous casting minimizes repeated melting steps, which are a major source of oxygen contamination in conventional copper strip processes. Fewer thermal cycles mean lower oxidation risk, making it easier to consistently achieve Low-Oxygen Copper Strip and Oxygen-Free Copper Strip standards. This consistency is especially important for customers who require large volumes of High-Purity Copper Strip with stable properties.

Environmental and energy considerations also play a role. Upward Continuous Casting Copper Strip is often more energy-efficient than traditional routes, supporting greener manufacturing. By reducing scrap rates and improving yield, producers can manufacture copper strip, Low-Oxygen Copper Strip, High-Purity Copper Strip, and Oxygen-Free Copper Strip with lower overall environmental impact. This aligns well with global sustainability goals and regulatory pressures.

From a technical validation standpoint, multiple pilot lines have demonstrated that Upward Continuous Casting Copper Strip can achieve oxygen levels comparable to those of oxygen-free copper produced by more complex methods. Through optimized furnace design, protective gas systems, and refined casting parameters, copper strip oxygen content can be tightly controlled. As a result, industrial-scale production of Low-Oxygen Copper Strip and even Oxygen-Free Copper Strip is no longer theoretical but increasingly practical.

Looking ahead, the industry consensus is forming. While challenges remain, particularly in equipment investment and process control, Upward Continuous Casting Copper Strip has proven its capability to support the production of High-Purity Copper Strip, Low-Oxygen Copper Strip, and Oxygen-Free Copper Strip. As technology continues to mature, more manufacturers are expected to adopt Upward Continuous Casting Copper Strip lines dedicated to high-end copper strip products.

In conclusion, the answer to the question Can Upward Continuous Casting of Copper Strip Achieve Oxygen-Free or Low-Oxygen Production? is increasingly clear. With proper raw materials, advanced equipment, and rigorous process management, Upward Continuous Casting Copper Strip can reliably produce copper strip that meets the demanding requirements of High-Purity Copper Strip, Low-Oxygen Copper Strip, and Oxygen-Free Copper Strip markets. This technology is not only reshaping how copper strip is manufactured today but also defining the future standards of the global copper processing industry.