From Copper Rods to Cables: Own Copper Rod Production Line Opens New Chapter

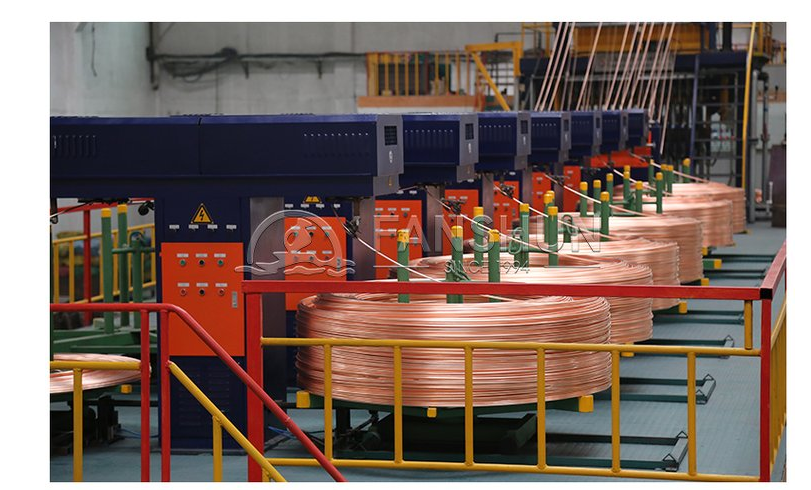

In a significant step towards greater manufacturing independence, a new Copper Rod Continuous Casting and Rolling Line has been implemented to revolutionize the production of copper cables. This state-of-the-art machinery is set to transform the way companies manufacture wires, offering efficiency, quality, and a boost to in-house capabilities. The move to establish an in-house Wire Copper Rod Production Line signals a shift in the industry, emphasizing control over quality and flexibility in production.

Expanding Capabilities with Copper Rod Continuous Casting and Rolling Line

The installation of the Copper Rod Continuous Casting and Rolling Line marks a strategic decision to optimize the manufacturing of copper wire rods. Traditionally, companies relied on external suppliers for copper rods, which were then drawn into wire suitable for cable production. This new machinery allows for seamless transition from raw material to finished product, saving time and costs while enhancing product quality. The Copper Rod Continuous Casting and Rolling Line efficiently converts molten copper into high-quality copper rods, which can then be used in a variety of applications, including cable manufacturing.

By using the Copper Rod Continuous Casting and Rolling Line, companies now have the ability to produce copper rods that meet their precise specifications. This control over production means improved quality assurance and the flexibility to adapt to changing market demands. Moreover, the machinery's advanced technology ensures minimal waste and maximized yield, making it a valuable addition to any facility focused on efficiency.

Advantages of an In-House Wire Copper Rod Production Line

The decision to implement an in-house Wire Copper Rod Production Line offers numerous advantages. One of the most significant benefits is the ability to streamline the manufacturing process. Instead of sourcing pre-made copper rods, companies can now produce their own, reducing dependency on suppliers and fluctuations in raw material prices. This move towards self-reliance also allows for better inventory management and faster response times to customer demands.

Another key benefit of having a dedicated Wire Copper Rod Production Line is the improvement in product consistency. Quality control is easier to manage when the entire process is under one roof, from copper rod creation to the final cable product. This ensures that the copper wire rods produced meet the highest standards, leading to superior cables. In a competitive market where reliability is crucial, this capability gives manufacturers a distinct advantage.

Technological Advancements in the Copper Wire Rod Manufacturing Line

The introduction of a Copper Wire Rod Manufacturing Line reflects the latest advancements in the industry. Modern machinery incorporates automated processes that not only enhance production speed but also ensure uniformity in the copper rods produced. The Copper Wire Rod Manufacturing Line uses sophisticated monitoring systems to maintain precise control over temperatures, dimensions, and other critical parameters, ensuring that each rod produced meets stringent quality criteria.

The addition of the Copper Wire Rod Manufacturing Line is also a response to the increasing demand for high-quality copper cables in various industries, from telecommunications to automotive. As companies seek to create more reliable and efficient electrical systems, the quality of the raw materials—specifically copper wire rods—becomes even more crucial. An in-house production line helps companies meet these demands without compromising on quality or performance.

Maximizing Efficiency with Copper Rod Production Equipment

One of the most exciting aspects of this new chapter in manufacturing is the introduction of specialized Copper Rod Production Equipment. These machines are designed to handle every step of the copper rod creation process, from melting and casting to rolling and cooling. This comprehensive system eliminates the need for multiple suppliers and reduces the complexities of coordinating with external partners. The in-house Copper Rod Production Equipment enables companies to control the entire process, reducing lead times and improving the overall efficiency of production.

The latest Copper Rod Production Equipment also features energy-efficient technologies that minimize power consumption while maximizing output. This not only reduces production costs but also aligns with modern sustainability goals. With the growing emphasis on eco-friendly manufacturing, companies are increasingly turning to equipment that offers both high efficiency and a smaller environmental footprint.

The Role of Copper Rod Upcasting Production Line in Modern Manufacturing

The Copper Rod Upcasting Production Line is another pivotal component in this new era of copper rod manufacturing. Unlike traditional methods, upcasting offers a way to produce oxygen-free copper rods, which are essential for applications requiring superior electrical conductivity and durability. The Copper Rod Upcasting Production Line allows manufacturers to produce copper rods with fewer impurities, resulting in a higher-quality product that is perfect for specialized cables.

Furthermore, the Copper Rod Upcasting Production Line is particularly well-suited for manufacturing smaller batches of high-quality copper rods. This flexibility is crucial in industries that require customized products or that experience frequent shifts in demand. The ability to quickly adjust production levels and specifications without sacrificing quality makes upcasting a valuable addition to any modern manufacturing setup.

Meeting Market Demands with an Integrated Approach

As the market for copper cables continues to grow, having an integrated production system is becoming increasingly important. A facility equipped with a Copper Rod Continuous Casting and Rolling Line, Wire Copper Rod Production Line, and Copper Wire Rod Manufacturing Line is well-positioned to meet the evolving needs of the industry. The capacity to control every aspect of production not only ensures a higher quality product but also provides a competitive edge in terms of pricing and delivery times.

The use of advanced Copper Rod Production Equipment and the precision of a Copper Rod Upcasting Production Line create an environment where manufacturers can confidently meet the demands of clients, whether they require standard copper rods or highly specialized products. This comprehensive approach to manufacturing supports a future where quality, efficiency, and innovation are at the forefront.

Conclusion: A New Era for Copper Rod Manufacturing

The establishment of an in-house copper rod production facility marks a significant milestone in manufacturing. With the integration of a Copper Rod Continuous Casting and Rolling Line, Wire Copper Rod Production Line, and a Copper Wire Rod Manufacturing Line, companies are setting new standards for quality and efficiency. The addition of specialized Copper Rod Production Equipment and the advantages of a Copper Rod Upcasting Production Line further solidify the position of manufacturers in a competitive market.

This move represents not just a technological advancement, but a strategic shift towards greater control and independence in the production process. As the industry continues to evolve, those with in-house capabilities will be better prepared to face challenges and seize opportunities, leading to a new chapter in the world of copper rod and cable manufacturing.