How Are Aluminum Ingots Efficiently Produced from Aluminum Scrap?

In today’s circular economy, the ability to turn aluminum scrap into high-quality aluminum ingot efficiently is critical to meeting global sustainability goals. Thanks to advancements in metallurgy and manufacturing automation, modern plants are using equipment like the Aluminum Melting Furnace, Molten Aluminum Trough, Aluminum Ingot Casting Machine, and a precision-engineered system of Ingot Mold units to produce thousands of aluminum ingot pieces per day.

Step 1: Melting Aluminum Scrap in the Aluminum Melting Furnace

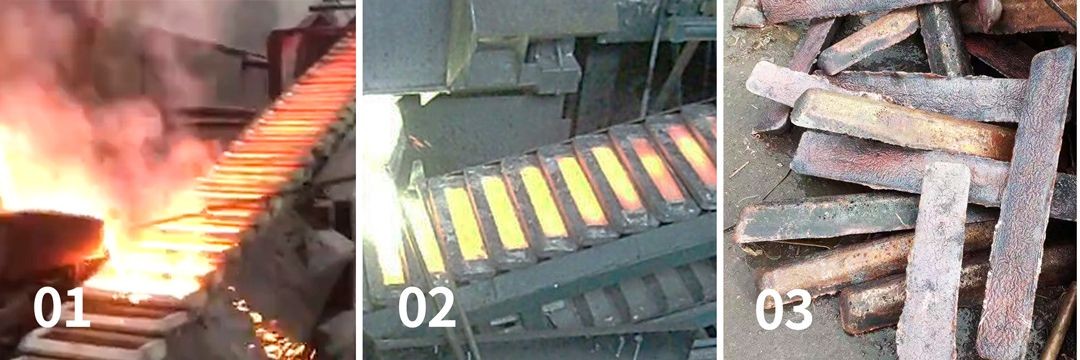

The production of the aluminum ingot begins in the Aluminum Melting Furnace. Scrap aluminum—sourced from industrial cuttings, beverage cans, or obsolete products—is fed into the Aluminum Melting Furnace, which melts it at temperatures over 750°C.

This high-efficiency Aluminum Melting Furnace is the starting point for every aluminum ingot. Designed to minimize oxidation and energy waste, it ensures that the molten metal will meet the necessary purity standards before traveling down the Molten Aluminum Trough.

The Aluminum Melting Furnace plays a vital role in removing impurities through fluxing and degassing. Only when the molten aluminum reaches the right composition can it be successfully molded into consistent, defect-free aluminum ingot using the downstream Aluminum Ingot Casting Machine and Ingot Mold units.

Step 2: Flow Control with the Molten Aluminum Trough

The molten metal is then guided into a Molten Aluminum Trough, a highly insulated channel connecting the Aluminum Melting Furnace to the casting section. The Molten Aluminum Trough ensures that the metal stays at the optimal temperature and flows steadily to the Aluminum Ingot Casting Machine.

A temperature drop in the Molten Aluminum Trough could lead to incomplete filling of the Ingot Mold, resulting in flawed aluminum ingot pieces. That's why the Molten Aluminum Trough is made from heat-resistant materials that maintain metal fluidity and prevent contamination before it reaches the Ingot Mold.

In advanced systems, the Molten Aluminum Trough branches into multiple paths, allowing for simultaneous feeding of multiple Ingot Mold setups, enabling mass production of aluminum ingot on a continuous basis.

Step 3: Casting with the Aluminum Ingot Casting Machine

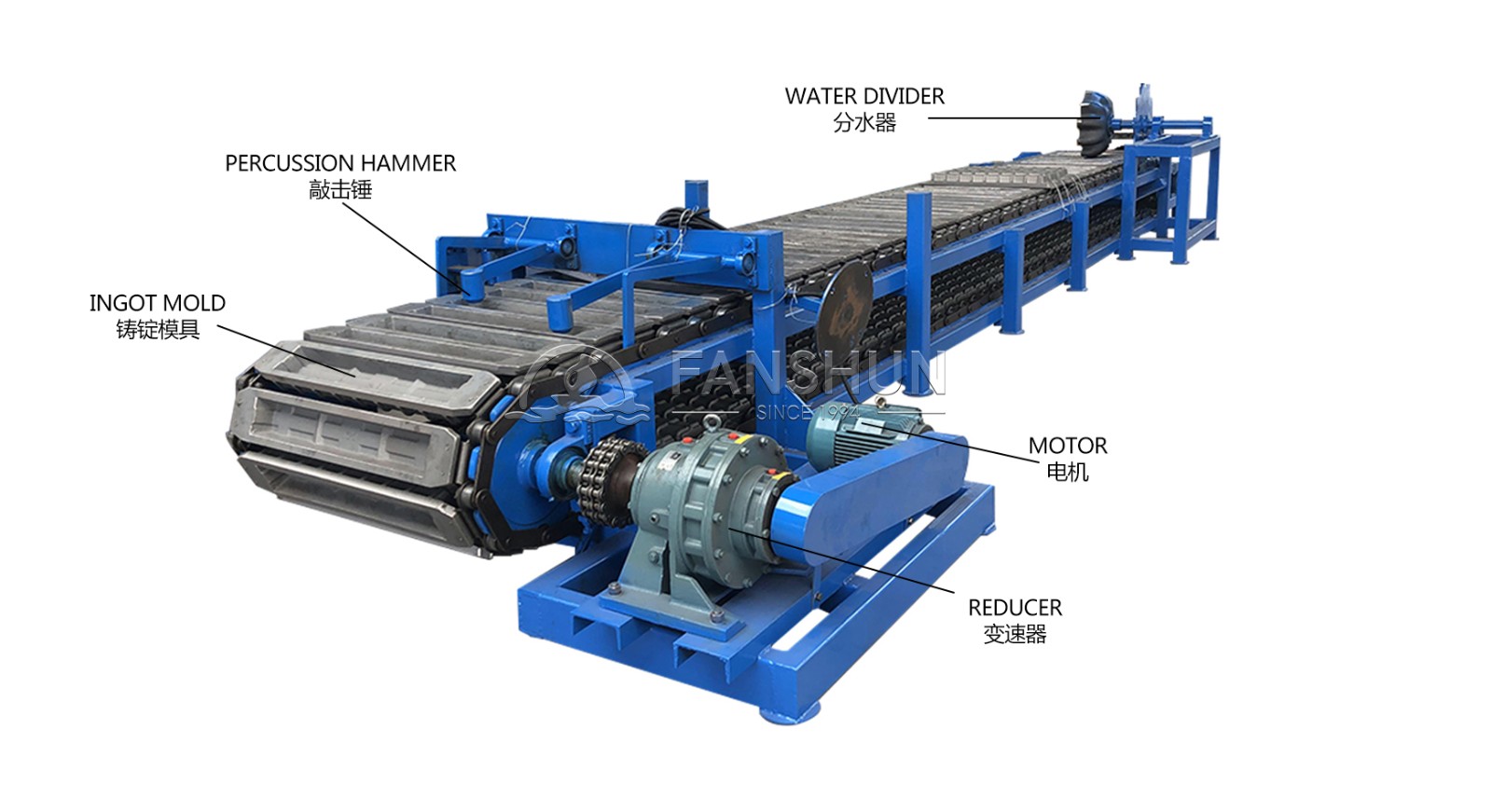

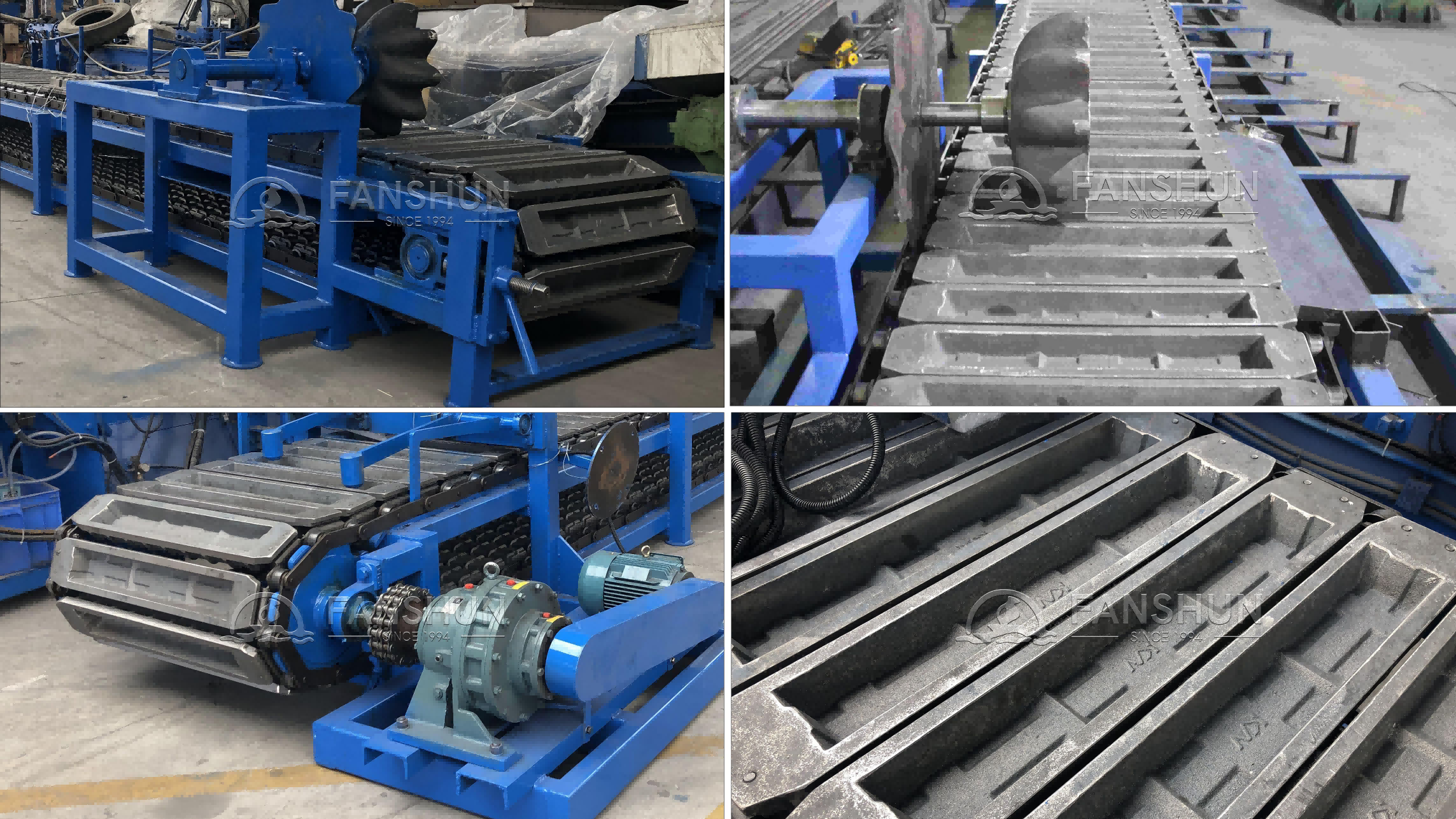

Once the molten aluminum reaches the Aluminum Ingot Casting Machine, it is metered into an array of Ingot Mold cavities. The Aluminum Ingot Casting Machine is fully automated and precisely controls pouring, cooling, and demolding.

The Aluminum Ingot Casting Machine rotates or conveys multiple Ingot Mold trays through the pouring zone. Each Ingot Mold is aligned, filled, cooled, and then opened for ingot removal. This allows for a high-speed production rate where dozens of aluminum ingot are produced every minute.

The Aluminum Ingot Casting Machine works in harmony with the Ingot Mold—and without a well-designed Ingot Mold, it would be impossible to achieve dimensional precision or surface quality in each aluminum ingot.

The Heart of the Process: Ingot Mold

At the core of every successful aluminum ingot casting operation is the Ingot Mold. A single Ingot Mold determines the size, shape, and cooling dynamics of the aluminum ingot. A facility might operate hundreds of Ingot Mold units simultaneously in a casting cycle.

Each Ingot Mold must be:

Made from high-strength cast iron or graphite

Able to withstand repeated thermal shocks

Properly preheated to avoid thermal cracking

Coated to prevent the aluminum ingot from sticking

A worn or poorly maintained Ingot Mold can cause surface cracks, shrinkage cavities, or uneven cooling in the aluminum ingot. That’s why factories invest in large inventories of Ingot Mold units and inspect them daily.

The Ingot Mold also directly affects solidification. Fast or uneven cooling inside the Ingot Mold will lead to internal stress in the aluminum ingot, which can later fail under machining or rolling.

Top casting plants now use smart sensors embedded in each Ingot Mold to monitor temperature and pouring time. These real-time systems allow casting operators to react immediately if a particular Ingot Mold is underperforming.

By using consistent geometry and robust construction, every Ingot Mold contributes to reduced scrap rates and improved aluminum ingot quality.

In large-scale operations, over 150 Ingot Mold units may be in constant use across multiple lines, fed by the same Aluminum Ingot Casting Machine and Molten Aluminum Trough system. Even the way Ingot Mold units are cooled—with water spray or air jets—impacts the hardness and grain size of the final aluminum ingot.

Every improvement in Ingot Mold design—be it deeper cavity shaping, enhanced release coatings, or better thermal conductivity—translates to better aluminum ingot quality and higher production uptime.

Final Handling and Packaging

After the Ingot Mold cools the molten metal into a solid aluminum ingot, the ingot is removed mechanically and inspected. Modern lines use robotic arms or automatic ejectors to lift the aluminum ingot out of the Ingot Mold without damage.

The empty Ingot Mold is then recoated, preheated, and reintroduced into the casting cycle. This repeatability is what makes the Ingot Mold system such an important part of continuous production.

Once cooled, each aluminum ingot is stacked and bundled for transportation. The surface smoothness and uniform shape achieved by the Ingot Mold makes storage and further processing much more efficient.

Conclusion

The efficient production of aluminum ingot from scrap is only possible because of the synchronized interaction between five essential components: the Aluminum Melting Furnace, Molten Aluminum Trough, Aluminum Ingot Casting Machine, and most critically, the Ingot Mold.

While the Aluminum Melting Furnace initiates the transformation, and the Molten Aluminum Trough preserves metal quality, it is the Ingot Mold, operated through the Aluminum Ingot Casting Machine, that ultimately determines the shape, strength, and reliability of every aluminum ingot.

In fact, one could argue that the Ingot Mold is the unsung hero of modern casting lines. A single improvement in Ingot Mold design can impact every downstream process that uses an aluminum ingot, from rolling mills to extrusion plants.

As demand for clean, consistent aluminum ingot continues to grow globally, investing in better Ingot Mold systems, smarter Aluminum Ingot Casting Machine control, and efficient Molten Aluminum Trough designs will be the key to sustainable success.