How Does a Brass Rod Horizontal Continuous Casting Production Line Work?

In modern non-ferrous metal manufacturing, efficiency and precision define success. Among the most advanced technologies in this field, the Brass Rod Horizontal Continuous Casting Production Line has become the preferred choice for producing high-quality brass rod, bronze bar, and copper rod products. This production line integrates melting, casting, and cooling into a continuous process, ensuring stable output, uniform composition, and exceptional surface quality. With the rise of the Copper Rod Continuous Casting Line, many manufacturers now compare these systems to select the best solution for bronze bar or brass rod production.

The Core Concept of Horizontal Continuous Casting

Unlike traditional vertical casting, the Horizontal Continuous Casting Production Line operates horizontally, allowing molten metal to flow evenly through a crystallizer to form long, continuous rods or bars. This horizontal configuration enhances control over the metal flow rate, cooling speed, and solidification uniformity, resulting in dense and defect-free structures. Whether you are producing brass rod, bronze bar, or utilizing a Copper Rod Continuous Casting Line, this system delivers consistent metallurgical performance.

The Brass Rod Horizontal Continuous Casting Machine is the central component of the entire line. It ensures precise temperature management, uniform solidification, and smooth extraction of the cast product. By integrating automatic control systems, operators can monitor casting speed, temperature curves, and cooling water pressure in real time, achieving unmatched stability during production. The Copper Rod Continuous Casting Line also shares these monitoring features but is tailored for high-purity copper, while the Brass Rod Horizontal Continuous Casting Machine is optimized for alloys like bronze bar or brass rod.

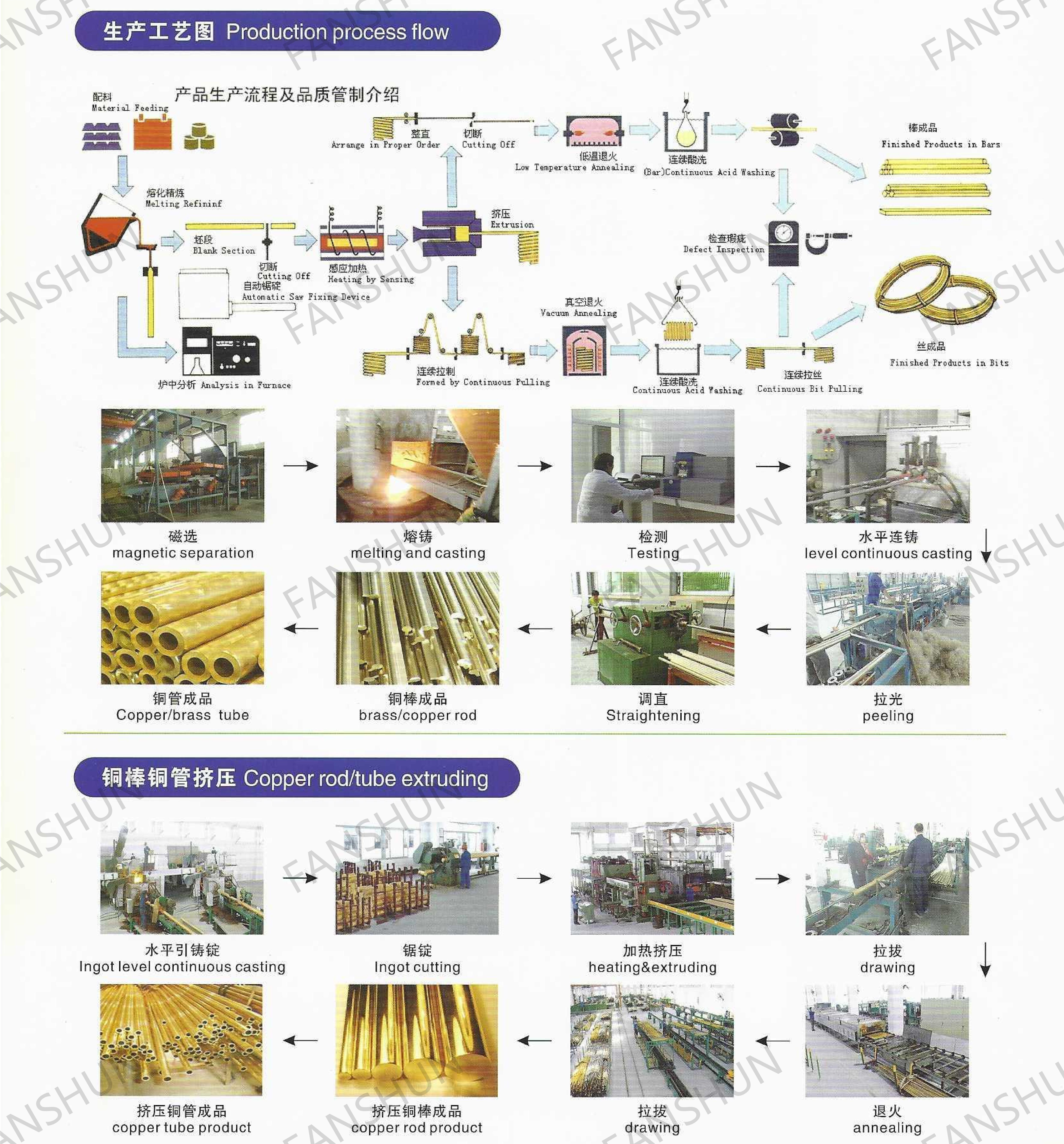

Step-by-Step: How the Process Works

Melting: The process begins in the induction melting furnace. Scrap brass or copper cathode materials are melted and alloyed to achieve the desired composition for brass rod, bronze bar, or copper rod production. The Copper Rod Continuous Casting Line uses similar melting techniques optimized for copper.

Refining and Filtering: Before casting, the molten metal passes through filters to remove impurities, ensuring the purity of the final bronze bar or brass rod. Proper filtration is especially critical for bronze bar production to maintain mechanical strength and surface quality.

Casting: The purified molten metal enters the Brass Rod Horizontal Continuous Casting Machine through a tundish and crystallizer. The crystallizer rapidly cools the metal surface while maintaining a semi-solid core, which is then continuously pulled forward. Bronze bar production benefits greatly from this uniform solidification, as do copper rods produced by a Copper Rod Continuous Casting Line. Each bronze bar exhibits fine grains, uniform alloy distribution, and minimal internal stress, making it suitable for industrial and decorative applications.

Cooling and Cutting: The partially solidified brass rod or bronze bar moves through a controlled water-cooling system, completing solidification. It is then cut to the required lengths with an automatic cutting unit. The Copper Rod Continuous Casting Line employs similar precision cutting for consistent rod length and quality. High-quality bronze bar finishing ensures superior machinability and durability.

Finishing: The rods or bars can undergo straightening, peeling, or polishing operations, depending on the final application. Producing bronze bar with precise dimensional control guarantees compatibility with downstream extrusion or machining processes.

Advantages of the Brass Rod Horizontal Continuous Casting Machine

The Brass Rod Horizontal Continuous Casting Production Line is known for its energy efficiency, reduced oxidation loss, and superior product uniformity. Compared to vertical casting, it minimizes material waste and offers better productivity. Manufacturers of brass rod, bronze bar, and copper rod value this technology for its ability to maintain consistent diameter, smooth surface finish, and excellent machinability.

In addition, the Copper Rod Continuous Casting Line—a similar system used for pure copper—shares many design principles with the Brass Rod Horizontal Continuous Casting Machine. Both utilize continuous casting to achieve tight metallurgical control, but the Brass Rod Horizontal Continuous Casting Production Line is specifically optimized for copper-zinc alloys, which require precise temperature regulation to prevent zinc evaporation and maintain composition balance. Producing bronze bar using this system guarantees uniform alloy distribution, fine grains, and superior mechanical properties.

Industrial Applications and Market Demand

Products made from brass rod, bronze bar, and copper rod are widely used in electrical components, sanitary valves, hardware fittings, and decorative materials. The Horizontal Continuous Casting Production Line enables mass production for these industries with stable quality and minimal downtime. As global demand for high-conductivity, corrosion-resistant copper alloys continues to grow, more manufacturers are upgrading to advanced Brass Rod Horizontal Continuous Casting Production Line systems or Copper Rod Continuous Casting Line systems to remain competitive. High-performance bronze bar production ensures that industrial requirements for strength, durability, and appearance are consistently met.

Furthermore, in regions where energy efficiency and automation are key priorities, the adoption of Copper Rod Continuous Casting Line and Brass Rod Horizontal Continuous Casting Machine systems is accelerating. These systems integrate smart control modules, allowing precise operation while reducing human intervention and operational risk. Whether producing bronze bar or brass rod, continuous casting technology ensures consistent quality, high output, and reliability.

The Future of Continuous Casting Technology

Continuous casting has revolutionized the production of brass rod, bronze bar, and copper rod materials. The transition from batch casting to the Horizontal Continuous Casting Production Line represents a leap toward smarter, cleaner, and more sustainable manufacturing. As automation and monitoring technologies advance, future versions of the Brass Rod Horizontal Continuous Casting Machine will feature real-time data analytics, AI-driven process control, and improved cooling efficiency. The Copper Rod Continuous Casting Line will similarly evolve, further enhancing precision and output. High-quality bronze bar production will benefit from these innovations, with improved metallurgical properties and reduced waste.

Conclusion

So, how does a Brass Rod Horizontal Continuous Casting Production Line work? It combines precision melting, controlled crystallization, and automated cutting in one seamless process. The result is a consistently high-quality brass rod or bronze bar, ready for use in various industrial applications. When compared to traditional methods or the Copper Rod Continuous Casting Line, this horizontal process stands out for its superior stability, reduced waste, and exceptional surface quality.

In short, the Brass Rod Horizontal Continuous Casting Machine represents the future of non-ferrous metal production — merging innovation, efficiency, and precision to redefine what’s possible in the casting industry. High-performance bronze bar production and copper rod manufacturing are now easier and more reliable than ever thanks to this advanced continuous casting technology.