How does a tilting gas furnace improve metal melting efficiency compared to traditional furnaces?

In today’s foundry and non-ferrous metal industry, efficiency, safety, and environmental compliance are more important than ever. Among the leading innovations transforming metal melting, the Gas fired aluminium melting furnace, oil-fired tilting furnace, Gas furnace for melting aluminum, Copper furnace, and Oil burning furnace are gaining widespread attention. Manufacturers often ask: How does a tilting gas furnace improve metal melting efficiency compared to traditional furnaces? The answer lies in enhanced productivity, energy efficiency, and operational flexibility.

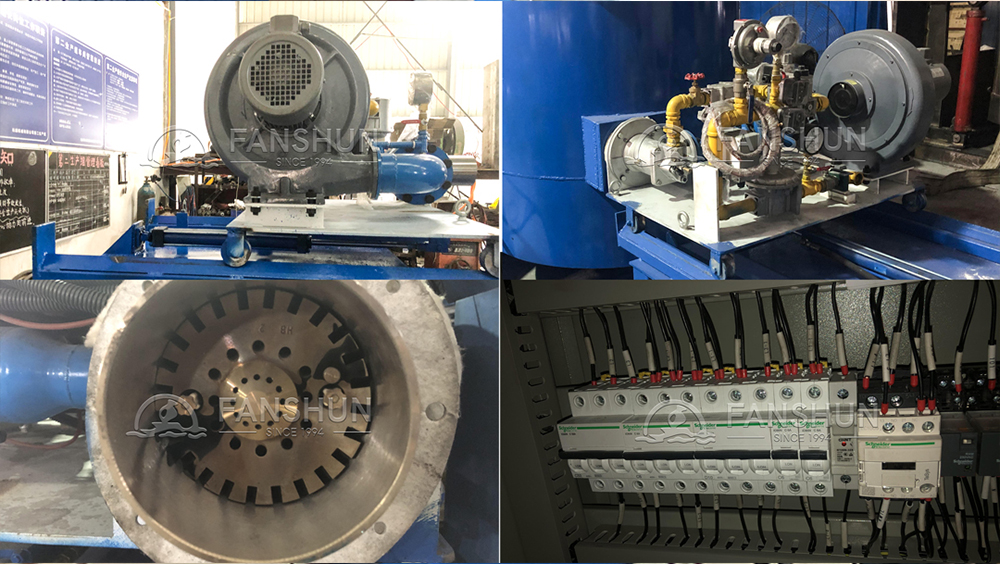

A Gas fired aluminium melting furnace provides uniform heat distribution, allowing aluminum scrap and ingots to melt quickly and efficiently. The tilting design enables precise pouring, reducing spillage and increasing yield. Similarly, an oil-fired tilting furnace delivers high thermal intensity while allowing operators to tilt the furnace for safe and accurate pouring. Both the Gas fired aluminium melting furnace and oil-fired tilting furnace reduce labor costs and improve throughput compared to stationary units.

The Gas furnace for melting aluminum has become a cornerstone for modern production lines. By incorporating advanced burner systems and precise temperature controls, a Gas furnace for melting aluminum minimizes energy waste and achieves consistent melt quality. Operators using the Gas furnace for melting aluminum report faster cycle times and improved alloy composition. Meanwhile, the Copper furnace plays a critical role in industries processing copper rods, wires, and sheets. The Copper furnace allows precise tilt-pouring, reducing oxidation and ensuring surface quality. A well-designed Copper furnace also supports multiple fuel sources, including gas and oil, which makes it adaptable to different plant requirements.

Efficiency gains with a Gas fired aluminium melting furnace are significant. It reduces fuel consumption and accelerates melting compared to traditional stationary units. The oil-fired tilting furnace provides similar advantages, enabling high-volume aluminum melting with lower energy use. The Gas furnace for melting aluminum ensures temperature consistency and reliable production output. The Copper furnace enhances the metallurgical quality of copper by maintaining uniform temperature and reducing surface defects. Even the Oil burning furnace has been updated with tilt-pouring mechanisms to provide safer handling and improved energy efficiency.

Industry professionals consistently highlight the benefits of the Copper furnace. Compared to older cupola units, a modern Copper furnace improves casting quality, reduces metal loss, and ensures consistent product specifications. In combination with a Gas fired aluminium melting furnace or Gas furnace for melting aluminum, the Copper furnace supports a full production line capable of handling aluminum and copper simultaneously. An oil-fired tilting furnace or Oil burning furnace complements these setups, providing flexibility for plants using oil-based fuels.

Customer feedback underscores the advantages. Foundries adopting a Gas fired aluminium melting furnace report higher yields and improved aluminum purity. Users of an oil-fired tilting furnace appreciate reduced labor and faster cycle times. The Gas furnace for melting aluminum offers consistent energy efficiency and environmental benefits. Operators of a Copper furnace emphasize superior surface quality, minimal oxidation, and precise pouring control. Even small and medium operations relying on an Oil burning furnace enjoy reliable heat and safer handling. The Copper furnace repeatedly proves its value in both heavy-duty industrial operations and specialized copper applications.

Market trends indicate that tilting furnace designs, including the Gas fired aluminium melting furnace, oil-fired tilting furnace, Gas furnace for melting aluminum, and Copper furnace, will dominate upgrades across the globe. The Oil burning furnace remains relevant in areas with abundant oil resources, while the Copper furnace continues to be indispensable for electrical and industrial copper applications. Adoption of a Gas fired aluminium melting furnace and a Gas furnace for melting aluminum increases productivity and reduces energy costs, while a Copper furnace improves product consistency. An oil-fired tilting furnace and an Oil burning furnace provide operational flexibility and energy efficiency.

In conclusion, tilting furnaces represent a significant advancement in metal melting technology. Whether using a Gas fired aluminium melting furnace, an oil-fired tilting furnace, a Gas furnace for melting aluminum, a Copper furnace, or an Oil burning furnace, manufacturers can achieve higher yields, improved safety, and energy savings. Traditional stationary furnaces are gradually being replaced as modern tilting designs demonstrate superior performance. The Copper furnace, in particular, has proven indispensable in enhancing copper product quality, while the Gas fired aluminium melting furnace, oil-fired tilting furnace, Gas furnace for melting aluminum, and Oil burning furnace deliver reliable, efficient, and environmentally compliant melting solutions.