How Does an Automatic Copper Rod Cutting Machine Improve Production Efficiency?

In today’s competitive manufacturing environment, precision and speed are more important than ever. The Automatic Copper Rod Cutting Machine has emerged as a key innovation in the metal processing industry. This advanced Copper Rod Cutting Machine is specifically engineered to cut copper rod with high speed, accuracy, and consistency. For companies producing electrical components, plumbing fittings, or industrial parts, the Automatic rod cutting machine offers a way to streamline production and reduce operational costs. It is also widely recognized as a modern form of Copper Rod Opening Machine, bridging the gap between raw material supply and finished product assembly.

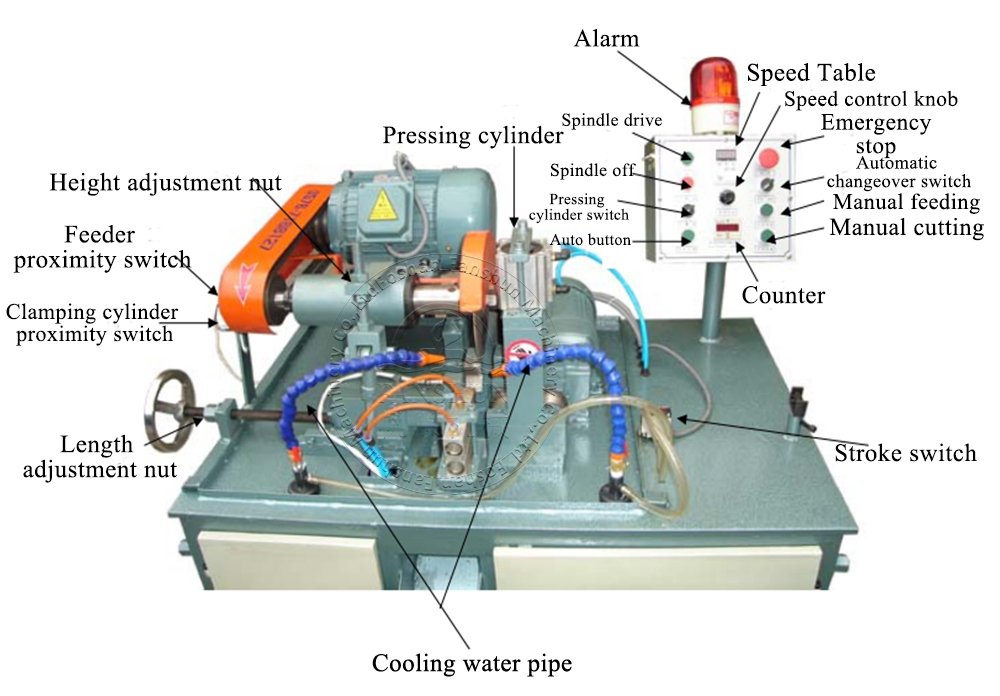

One of the greatest strengths of the Automatic Copper Rod Cutting Machine is its ability to integrate multiple steps into a single process. Traditionally, cutting copper rod involved manual measurement, feeding, and cutting, each step prone to human error. By contrast, the Copper Rod Cutting Machine automates feeding, measuring, and cutting in a continuous flow. An Automatic rod cutting machine can store multiple programs for different rod diameters and lengths, allowing manufacturers to quickly switch between production orders. As a Copper Rod Opening Machine, it reduces setup time and ensures every copper rod meets exact specifications.

Speed is another factor in improved efficiency. A state-of-the-art Automatic Copper Rod Cutting Machine can cut hundreds of copper rod pieces per hour without compromising quality. The Copper Rod Cutting Machine uses high-precision sensors and servo-driven feeding systems to deliver consistent length accuracy. This means an Automatic rod cutting machine can operate at maximum capacity while maintaining tight tolerances. When used as a Copper Rod Opening Machine, it removes one of the most common bottlenecks in manufacturing: slow and inconsistent cutting of copper rod stock.

Quality consistency directly impacts downstream processes. If copper rod pieces vary in length, it can cause fitting issues, misalignment, and product rejections. The Automatic Copper Rod Cutting Machine solves this by cutting each copper rod to exact dimensions. This Copper Rod Cutting Machine also produces cleaner cut surfaces, reducing the need for secondary finishing. With an Automatic rod cutting machine, every copper rod is ready for the next production stage, improving overall workflow. As a Copper Rod Opening Machine, it enhances both product quality and production speed.

Another benefit is reduced labor dependency. A single operator can supervise multiple Automatic Copper Rod Cutting Machine units, each functioning as an independent Copper Rod Cutting Machine. Because an Automatic rod cutting machine handles feeding and cutting automatically, the operator’s role shifts from manual labor to process monitoring. This lowers labor costs and makes it easier to scale production. For plants processing large volumes of copper rod, the Copper Rod Opening Machine offers a clear advantage over manual cutting systems.

Maintenance efficiency is also a contributing factor. Modern Automatic Copper Rod Cutting Machine designs include self-diagnostic systems and automatic lubrication. These features keep the Copper Rod Cutting Machine running smoothly with minimal intervention. An Automatic rod cutting machine can operate for long periods without downtime, which means the Copper Rod Opening Machine delivers more output per shift. For industries where copper rod demand is constant, such as electrical cable manufacturing or plumbing supply production, this reliability is essential.

Material savings are another hidden benefit. The Automatic Copper Rod Cutting Machine minimizes waste by optimizing each cut to maximize material usage. Unlike manual cutting, which may produce uneven offcuts, the Copper Rod Cutting Machine ensures every copper rod section is used efficiently. The Automatic rod cutting machine reduces scrap rates, translating directly into cost savings. As a Copper Rod Opening Machine, it contributes to sustainable manufacturing by conserving raw copper rod resources.

Flexibility in production is an increasingly important feature for manufacturers. The Automatic Copper Rod Cutting Machine can process a wide range of copper rod diameters and lengths without extensive retooling. This Copper Rod Cutting Machine capability means that an Automatic rod cutting machine can handle multiple product specifications in the same shift. As a Copper Rod Opening Machine, it enables manufacturers to respond quickly to changing market demands without sacrificing efficiency.

From an environmental perspective, the Automatic Copper Rod Cutting Machine is often more energy-efficient than older mechanical saws. The Copper Rod Cutting Machine uses optimized cutting speeds and precision controls to reduce power consumption. The Automatic rod cutting machine also generates less heat and noise, improving the workplace environment. As a Copper Rod Opening Machine, it aligns with modern industry goals for greener, more efficient operations while processing copper rod at high volumes.

In summary, the Automatic Copper Rod Cutting Machine is a transformative tool for modern manufacturing. By combining speed, accuracy, consistency, and flexibility, the Copper Rod Cutting Machine enhances the processing of copper rod in every aspect. An Automatic rod cutting machine not only cuts faster but also ensures higher product quality, lower labor costs, and reduced waste. As a Copper Rod Opening Machine, it serves as the critical link between raw copper rod and finished products, enabling manufacturers to meet growing market demands efficiently and sustainably.