Is a Horizontal Wire Drawing Machine Really Suitable for Large-Scale Copper Wire Production?

In recent industry developments, the fine copper fine wire drawing machine has gained substantial attention. Companies are increasingly investing in the fine copper fine wire drawing machine to meet surging demand in electronics, automotive, and renewable energy sectors. According to market analysts, the fine copper fine wire drawing machine can achieve micron-level precision, with the fine copper fine wire drawing machine delivering consistent diameter control. Experts say the fine copper fine wire drawing machine enhances tensile strength and improves conductivity. Industry users report that using a fine copper fine wire drawing machine reduces scrap rates and improves throughput.

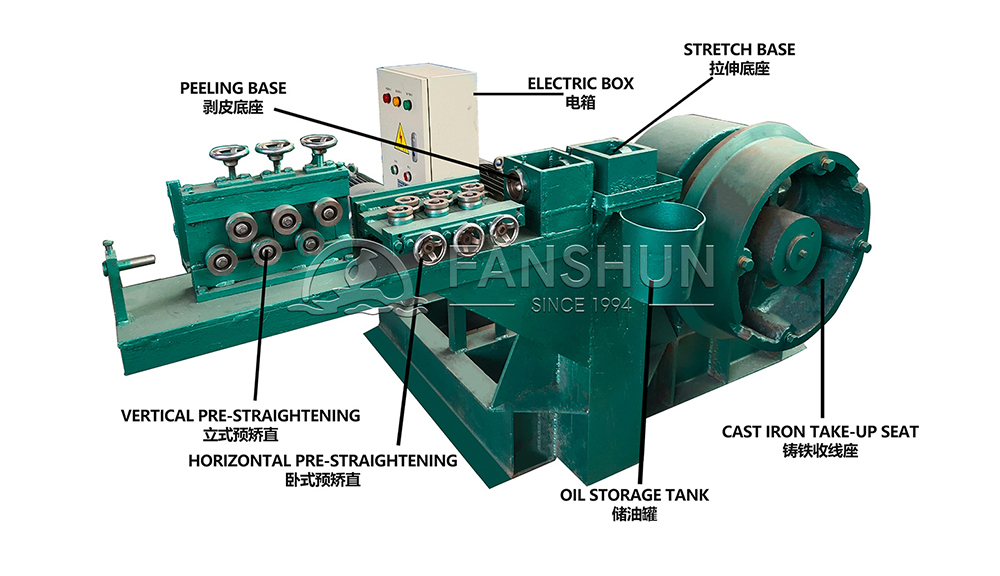

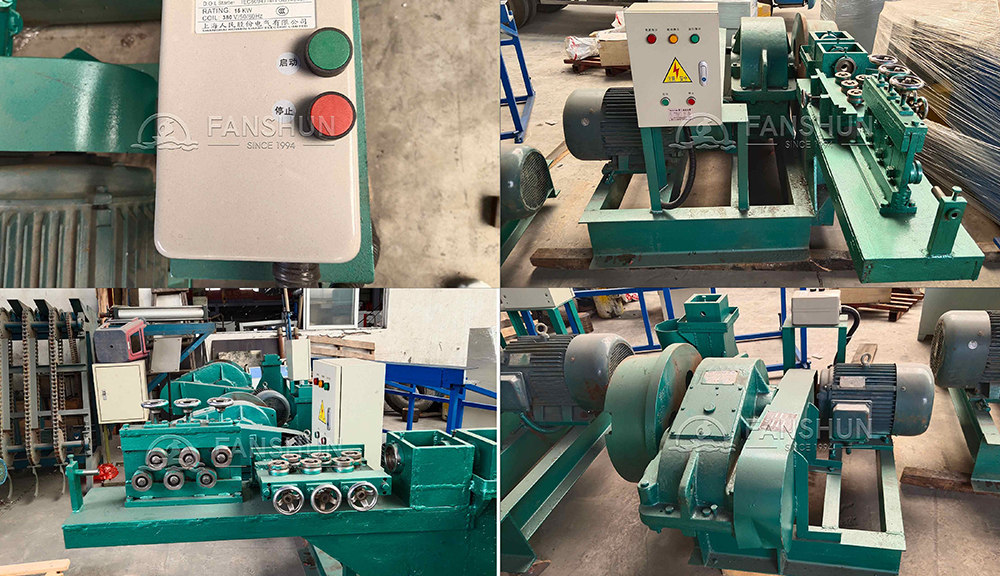

Simultaneously, the peeling and stretching machine has become a vital complement to drawing processes. The peeling and stretching machine prepares billets before drawing, achieving clean surfaces. Integration of a peeling and stretching machine with the main line boosts yield. Factories adopting the peeling and stretching machine find fewer defects during drawing. Operators note that the peeling and stretching machine ensures uniform feeding into the Copper wire drawing machine. Research organizations endorse the peeling and stretching machine for large-scale systems, confirming that the peeling and stretching machine cuts setup time in half. Manufacturers praise the peeling and stretching machine for automation and precision, stating that the peeling and stretching machine enhances productivity and minimizes manual labor.

The core equipment remains the Copper wire drawing machine. A modern Copper wire drawing machine for mass production operates with high-speed capstans, programmable draws, and attached automation. In factory test runs, the Copper wire drawing machine sustains continuous runs of hundreds of hours. Engineers report that the Copper wire drawing machine maintains key tolerances under heavy loads. They assert that the Copper wire drawing machine lowers per-meter cost. When combined with an optimized Fine Copper fine wire drawing machine subsystem, the Copper wire drawing machine delivers ultra-fine gauges. The Copper wire drawing machine achieves output up to several tons per shift. Use of a Copper wire drawing machine with inline inspection ensures quality control, with redundant sensors to monitor diameter and surface.

Equally important is surface quality. Enter the Metal Surface Grinding Polishing Machine—a final polishing stage that guarantees aesthetic and functional finish. The Metal Surface Grinding Polishing Machine handles various copper wire diameters, smoothing micro-scratches. With the Metal Surface Grinding Polishing Machine, wires develop reflective surfaces, improving solderability. Reports from quality control reveal that using a Metal Surface Grinding Polishing Machine decreased roughness by over 40%. Engineers integrating the Metal Surface Grinding Polishing Machine into the line note reduced downstream cleaning. The Metal Surface Grinding Polishing Machine also polishes after drawing and before wrapping, ensuring a premium feel. Technical advisors say the Metal Surface Grinding Polishing Machine is essential for sectors like aerospace, where finish matters. Many suppliers now bundle Metal Surface Grinding Polishing Machine units with Copper wire drawing machine lines for turnkey solutions.

Another key type is the Samp wire drawing machine, a smaller-capacity but versatile unit used for R&D and specialty wires. The Samp wire drawing machine allows process validation at pilot scale. Universities and labs adopt the Samp wire drawing machine to experiment with alloys. When paired with a peeling and stretching machine, the Samp wire drawing machine provides a flexible micro‑production line. Engineers use the Samp wire drawing machine to test new lubricants, drawing dies, and heat treatment parameters. Suppliers advertise the Samp wire drawing machine as ideal for fine-tuning before full-scale deployment. Even in production, the Samp wire drawing machine is used for prototyping new wire diameters. Reports show the Samp wire drawing machine helped reduce development cycles.

Across these systems, the fine copper fine wire drawing machine, peeling and stretching machine, Copper wire drawing machine, Metal Surface Grinding Polishing Machine, and Samp wire drawing machine form a holistic production ecosystem. The fine copper fine wire drawing machine ensures ultra-fine gauge capabilities. The peeling and stretching machine readies input material. The Copper wire drawing machine delivers scale. The Metal Surface Grinding Polishing Machine finalizes finish. The Samp wire drawing machine supports innovation.

Market forecasts predict growth of more than 8% annually. Suppliers tailor complete solutions: from fine copper fine wire drawing machine modules to lines with integrated peeling and stretching machine, Copper wire drawing machine, Metal Surface Grinding Polishing Machine, and Samp wire drawing machine. Factory case studies highlight improved outputs: 30% more throughput, 25% lower scrap, and premium finish thanks to Metal Surface Grinding Polishing Machine polishing.

For large-scale copper wire production, is a horizontal machine setup—centered on the Copper wire drawing machine—really suitable? The evidence suggests yes. When configured with fine copper fine wire drawing machine subsections, a peeling and stretching machine inlet, inline Metal Surface Grinding Polishing Machine, and optional Samp wire drawing machine line for R&D, the overall setup offers flexibility, quality, and scale.

In conclusion, the combination of fine copper fine wire drawing machine, peeling and stretching machine, Copper wire drawing machine, Metal Surface Grinding Polishing Machine, and Samp wire drawing machine addresses modern demands. Horizontal configurations streamline footprint and automation. As demand rises, these systems will define next-gen copper wire production lines—demonstrating that horizontal wire drawing machines, when properly integrated, are indeed suitable for large-scale copper wire production.