Is it feasible to produce brass bars from scrap copper? How does the production line achieve resource recycling?

As global industries seek sustainable solutions to reduce waste and reuse materials, the question arises: Is it feasible to produce brass bars from scrap copper? The answer is a resounding yes. With the evolution of modern technology and production line optimization, the transformation of Brass Scrap into high-quality copper bar products has become not only practical but highly efficient and cost-effective. In this article, we explore how the latest brass bar production lines, including Producing copper rod furnaces, Horizontal Continuous Casting Machine, and Brass Bar Cutting Machine, work in unison to achieve effective resource recycling.

The Potential of Brass Scrap

Brass Scrap is a valuable raw material composed mainly of copper and zinc. Recycling Brass Scrap into usable products like copper bar significantly reduces the environmental impact of mining and refining virgin copper. Every ton of recycled Brass Scrap saves energy, reduces CO2 emissions, and helps conserve natural resources. Modern production lines are specifically designed to maximize the reuse of Brass Scrap by melting, casting, drawing, and shaping it into standard or customized copper bar forms. Brass Scrap is not only cost-effective but also environmentally responsible, and the demand for Brass Scrap in copper bar production continues to grow worldwide.

Melting Stage: Producing Copper Rod Furnaces

The journey begins with Producing copper rod furnaces, which play a crucial role in the melting phase. These specialized furnaces are engineered to melt Brass Scrap efficiently while minimizing oxidation and metal loss. Today’s Producing copper rod furnaces incorporate energy-saving burners and automated temperature control systems to ensure consistent melting conditions. In many production facilities, the Producing copper rod furnaces operate continuously, feeding melted material into the casting system, and are optimized to handle high volumes of Brass Scrap without compromising quality. This process results in a homogenous melt that is ideal for high-quality copper bar formation.

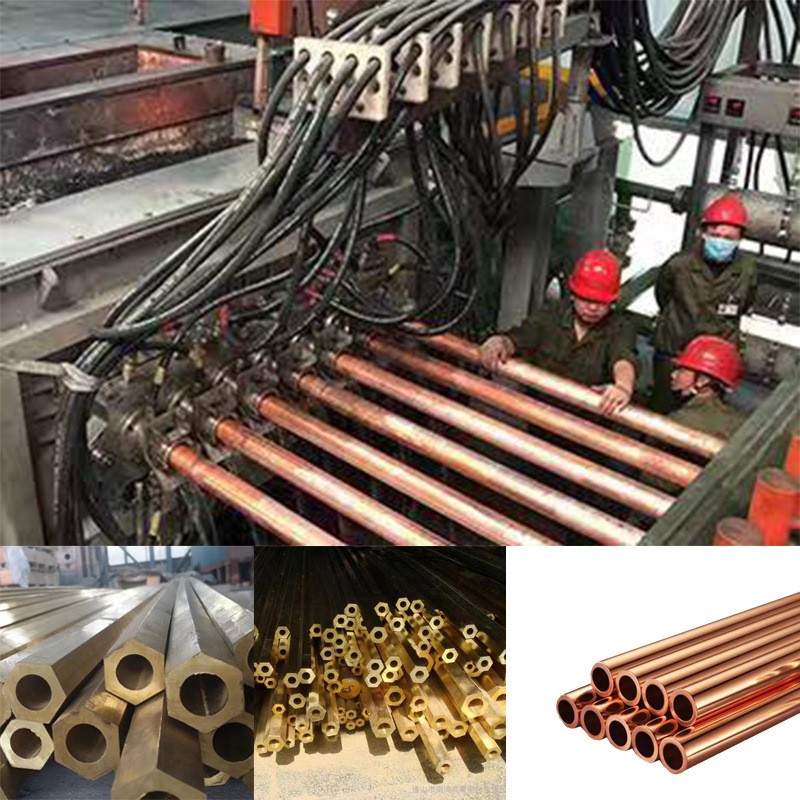

Casting Phase: Horizontal Continuous Casting Machine

Once the Brass Scrap is melted in the Producing copper rod furnaces, the molten metal is transferred to the Horizontal Continuous Casting Machine. This is a critical step in ensuring the quality and consistency of the final copper bar. The Horizontal Continuous Casting Machine provides a controlled environment for solidifying molten brass into semi-finished copper bar formats. This machine ensures precise temperature regulation, mold cooling, and casting speed, which are vital to maintain the mechanical properties of the resulting copper bar. With advanced automation, the Horizontal Continuous Casting Machine can process various shapes and sizes, supporting both round and hexagonal copper bar production. The versatility and efficiency of this system have made it a staple in Brass Scrap recycling facilities.

Cutting and Finishing: Brass Bar Cutting Machine

After casting, the copper bar is conveyed to the Brass Bar Cutting Machine for precise sizing. This machine is designed for high-speed, high-accuracy operations, enabling manufacturers to meet customer specifications efficiently. The Brass Bar Cutting Machine can handle a wide range of diameters and lengths, supporting mass production with minimal material waste. It is equipped with programmable logic controllers (PLCs) to automate the cutting process, improving productivity and reducing human error. The clean cuts produced by the Brass Bar Cutting Machine also prepare the copper bar for further processes like polishing, straightening, or threading. The efficiency of the Brass Bar Cutting Machine further increases the recycling rate of Brass Scrap by reducing material loss.

Integrated Recycling Workflow

The integrated workflow of Producing copper rod furnaces, Horizontal Continuous Casting Machine, and Brass Bar Cutting Machine creates a closed-loop system where Brass Scrap is efficiently turned into new copper bar products. This production model is a key component of circular economy principles, which focus on reducing waste and maximizing resource efficiency. Manufacturers benefit from lower raw material costs, reduced environmental compliance burdens, and enhanced brand reputation for sustainability.

Each Producing copper rod furnace is calibrated to optimize melting rates for various types of Brass Scrap, ensuring homogeneity in the final melt. Simultaneously, the Horizontal Continuous Casting Machine minimizes surface defects and internal porosity in the copper bar, while the Brass Bar Cutting Machine ensures consistency in length and finish. This streamlined system supports the continuous reuse of Brass Scrap, transforming it into valuable copper bar without compromising quality.

Market Applications and Benefits

The copper bar produced through this recycling method serves a wide array of industries, including plumbing, electronics, decorative hardware, and automotive manufacturing. Due to its excellent conductivity and machinability, copper bar is in constant demand globally. When sourced from recycled Brass Scrap, it provides an eco-friendly alternative without compromising performance. Businesses that focus on Brass Scrap recycling into copper bar are positioned to meet green manufacturing standards and improve overall environmental impact.

In terms of economic benefit, companies adopting this production line can drastically cut their reliance on virgin copper. By implementing advanced Producing copper rod furnaces, optimizing the Horizontal Continuous Casting Machine, and employing high-speed Brass Bar Cutting Machine systems, businesses not only improve their carbon footprint but also enhance overall production efficiency. The repeated and reliable transformation of Brass Scrap into copper bar ensures consistent material availability for downstream industries.

Conclusion

So, is it feasible to produce copper bar from Brass Scrap? Absolutely. Through the use of advanced Producing copper rod furnaces, precise Horizontal Continuous Casting Machine systems, and efficient Brass Bar Cutting Machine operations, manufacturers are turning waste into valuable products while promoting sustainability. The future of metal processing lies in resource recycling, and the copper bar production line is at the forefront of that transformation.

With more industries recognizing the value of Brass Scrap, the integration of these three core technologies ensures that producing copper bar will not only be economically viable but environmentally essential. As demand grows for both Brass Scrap reuse and sustainable copper bar production, forward-thinking manufacturers are already investing in these integrated systems to meet market needs and environmental goals.