Low straightening efficiency and unstable precision? Can a two-roll vertical straightening machine really solve these problems?

In today’s metal processing and steel fabrication industries, low straightening efficiency and unstable precision remain two of the most frequently discussed production bottlenecks. Manufacturers across construction, automotive, machinery, and metal products sectors are constantly asking the same question: Low straightening efficiency and unstable precision? Can a two-roll vertical straightening machine really solve these problems?

As market competition intensifies and customers demand higher dimensional accuracy, traditional straightening solutions are gradually revealing their limitations. This is where the Vertical Two-Roll Straightening Machine emerges as a critical upgrade. More than just a piece of equipment, the Vertical Two-Roll Straightening Machine represents a shift toward precision manufacturing, stable output, and intelligent production.

Why traditional straightening struggles with efficiency and precision

Conventional straightening systems often rely on outdated mechanical structures, manual adjustment, and inconsistent force application. These shortcomings frequently lead to uneven stress distribution, repeated adjustments, and unstable straightening results. As a result, production lines experience frequent downtime, high scrap rates, and rising labor costs.

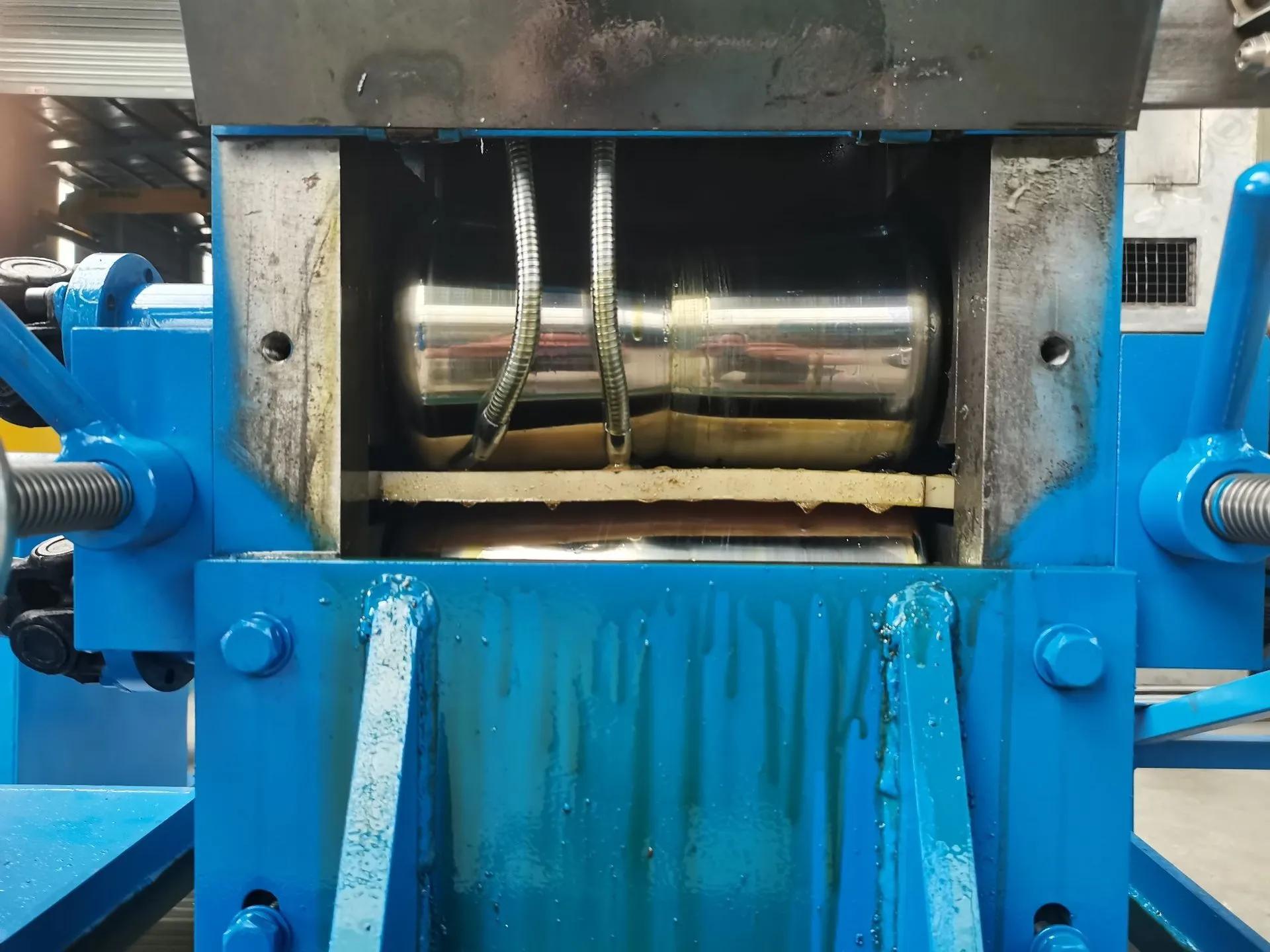

In contrast, modern Two-Roll Vertical Straightening Machine designs focus on structural rigidity, precise control, and efficient material flow. The Two-Roll Vertical Straightening Machine optimizes the straightening path by using a vertical configuration, ensuring consistent contact between rolls and material. This design dramatically improves straightening stability while maintaining high throughput.

The role of Two-Roll Straightening Equipment in modern factories

As factories move toward automation and smart manufacturing, Two-Roll Straightening Equipment has become an essential part of production lines. Unlike multi-roll systems that require complex calibration, Two-Roll Straightening Equipment simplifies adjustment while delivering reliable results. With fewer moving parts and a more direct force application, Two-Roll Straightening Equipment reduces maintenance requirements and enhances long-term operational stability.

Many manufacturers report that upgrading to Two-Roll Straightening Equipment significantly improves productivity and reduces operator dependency. This transition not only increases output but also ensures consistent quality across batches.

Precision Straightening System: the core technological advantage

At the heart of every Vertical Two-Roll Straightening Machine lies an advanced precision Straightening System. This precision Straightening System is designed to deliver accurate force control, repeatable settings, and stable straightening performance across various material specifications.

The precision Straightening System allows operators to fine-tune straightening parameters with minimal effort. By maintaining consistent pressure and alignment, the precision Straightening System ensures that each bar, rod, or wire meets strict dimensional tolerances. For industries where precision is non-negotiable, the precision Straightening System becomes a decisive factor in equipment selection.

Achieving High-Efficiency Straightening without compromising quality

One of the most common concerns in metal processing is whether High-Efficiency Straightening can coexist with high precision. The answer lies in the design philosophy of the Two-Roll Vertical Straightening Machine. By integrating optimized roll geometry and an intelligent precision Straightening System, manufacturers achieve true High-Efficiency Straightening without sacrificing accuracy.

High-Efficiency Straightening means faster processing speeds, reduced cycle times, and lower energy consumption. With the Vertical Two-Roll Straightening Machine, High-Efficiency Straightening becomes a standard operating condition rather than an occasional performance peak.

Vertical design advantages in straightening applications

The vertical layout of the Vertical Two-Roll Straightening Machine offers several operational benefits. Gravity-assisted feeding improves material stability, while vertical force distribution enhances straightening consistency. Compared to horizontal machines, the Vertical Two-Roll Straightening Machine occupies less floor space and integrates more easily into existing production lines.

This vertical configuration is a defining feature of the Two-Roll Vertical Straightening Machine, allowing it to adapt to diverse materials and diameters while maintaining High-Efficiency Straightening standards.

Industry applications of Two-Roll Straightening Equipment

From construction steel to automotive components, Two-Roll Straightening Equipment supports a wide range of industrial applications. Manufacturers processing round bars, wire rods, and precision shafts rely on Two-Roll Straightening Equipment to maintain consistent quality under high-volume production.

In sectors where quality audits and traceability are critical, the precision Straightening System embedded in Two-Roll Straightening Equipment ensures repeatable results. This reliability directly contributes to customer satisfaction and long-term brand credibility.

Cost efficiency and long-term value

Investing in a Vertical Two-Roll Straightening Machine is not just about immediate performance gains. Over time, the reduced maintenance requirements of Two-Roll Straightening Equipment and the stability of the precision Straightening System translate into lower total cost of ownership.

By enabling High-Efficiency Straightening, manufacturers reduce energy consumption and labor input. The Two-Roll Vertical Straightening Machine thus delivers measurable economic benefits alongside technical improvements.

Meeting future manufacturing demands

As industrial standards continue to evolve, the demand for High-Efficiency Straightening and precision-controlled processes will only increase. The Vertical Two-Roll Straightening Machine is designed to meet these future demands through scalable automation and adaptable control systems.

With continuous optimization of the precision Straightening System, manufacturers can respond quickly to new material specifications and customer requirements. The flexibility of the Two-Roll Vertical Straightening Machine ensures it remains a valuable asset in dynamic production environments.

Conclusion: a clear answer to a common question

So, low straightening efficiency and unstable precision? Can a two-roll vertical straightening machine really solve these problems? The growing adoption of the Vertical Two-Roll Straightening Machine, the proven reliability of Two-Roll Straightening Equipment, and the technological maturity of the precision Straightening System provide a clear answer.

By combining High-Efficiency Straightening with stable, repeatable accuracy, the Two-Roll Vertical Straightening Machine offers a comprehensive solution for modern manufacturing challenges. For factories seeking productivity, quality, and long-term competitiveness, this technology is no longer optional—it is essential.