What Advantages Does a Straightening, Grinding, and Shearing Machine Offer in Boosting Productivity?

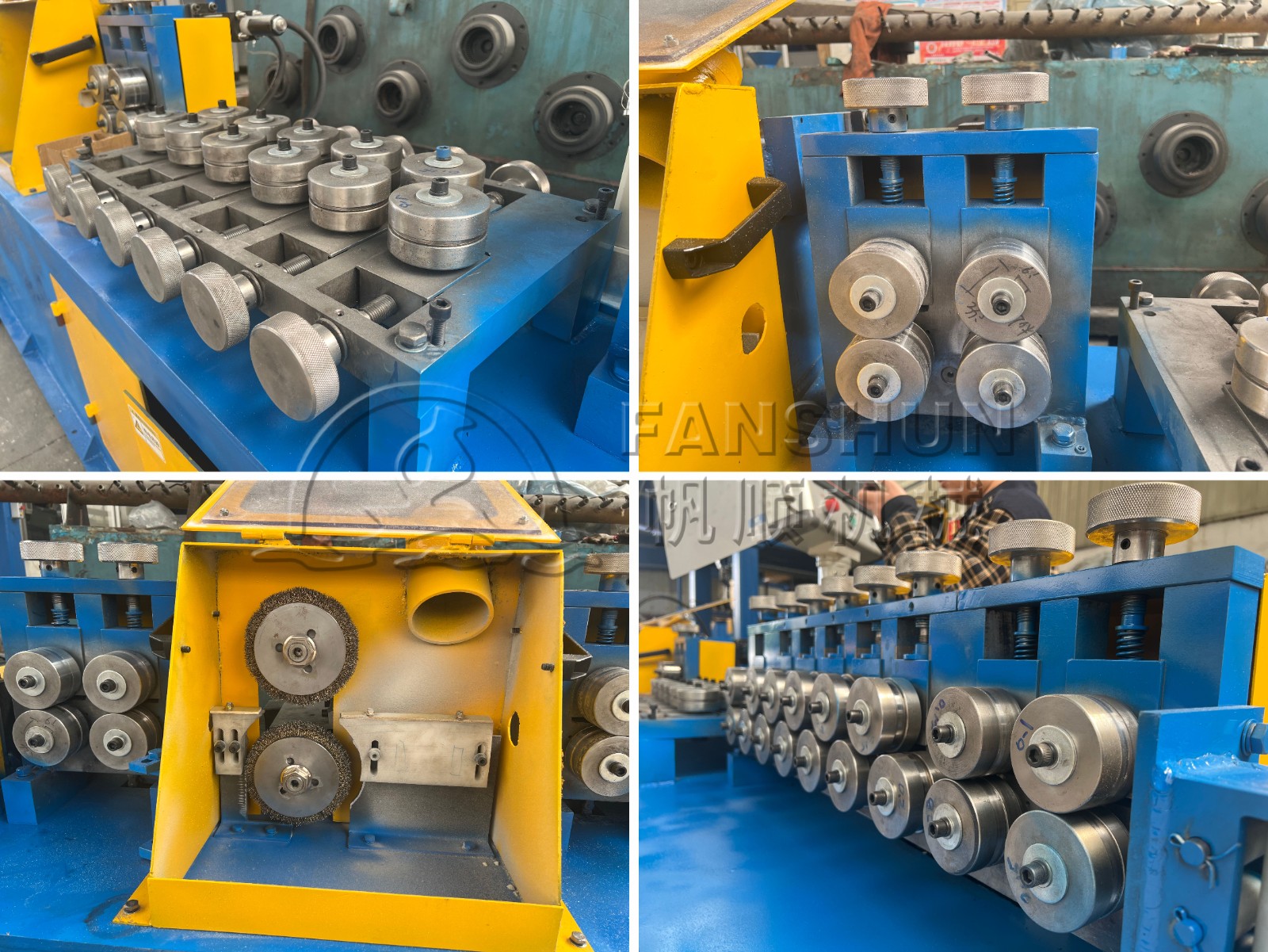

In the modern manufacturing landscape, efficiency is key to staying competitive, especially in industries dealing with high-demand materials such as copper. Straightening, grinding, and shearing machines have emerged as vital tools in boosting productivity in copper processing. These advanced machines not only streamline operations but also offer a host of other advantages that can significantly impact the bottom line of manufacturers. Specifically, Insulated Copper Flat Wire Straightening and Cutting Machine, Copper Busbar Straightening and Grinding Machine, Flat Copper Wire Straightening and Cutting System, Copper Flat Wire Straightening, Polishing, and Shearing Machine, and Multi-functional Copper Flat Bar Processing Equipment have become indispensable for improving manufacturing processes.

1. Improved Material Precision and Quality

One of the primary advantages of machines like the Insulated Copper Flat Wire Straightening and Cutting Machine is their ability to provide unparalleled precision in straightening and cutting copper materials. Copper wires and bars are often prone to bending or distortion during the manufacturing or transport process. However, these straightening and cutting machines ensure that copper flat wires are perfectly straightened, thus reducing material waste. Moreover, they can cut copper to precise lengths, making them ideal for high-precision industries such as electrical and electronics manufacturing.

Similarly, the Copper Busbar Straightening and Grinding Machine helps in not only straightening but also grinding the busbars, ensuring a smoother surface that improves the busbar's performance and durability. This dual functionality ensures that manufacturers get the highest quality output while reducing the need for separate grinding machines, so the Copper Busbar Straightening and Grinding Machine is both cost-effective and time-saving.

2. Increased Throughput and Reduced Lead Time

The Flat Copper Wire Straightening and Cutting System is specifically designed to optimize the throughput of copper wire production. Flat Copper Wire Straightening and Cutting System can handle high volumes of copper wire, straightening and cutting them in a continuous and automated fashion. This high throughput means manufacturers can meet increasing demand without the need for more labor or time-consuming manual processes. The automation reduces human error and accelerates production, which leads to shorter lead times and faster turnaround for clients.

By implementing Copper Flat Wire Straightening, Polishing, and Shearing Machine, manufacturers can integrate three essential processes—straightening, polishing, and shearing—into a single machine, drastically cutting down the time spent on each step. This combination of functions enhances both efficiency and product quality, ensuring a smoother production process and enabling manufacturers to meet tight deadlines.

3. Versatility in Production Lines

The versatility of the Multi-functional Copper Flat Bar Processing Equipment makes it an invaluable asset in copper processing. This equipment can be used to straighten, grind, shear, and polish copper flat bars with ease. Its multi-functionality eliminates the need for multiple machines to perform different tasks, thus saving on space, maintenance, and energy costs. This versatility is especially beneficial for manufacturers working with various copper products, such as copper flat wires, busbars, and rods, as it allows them to process these materials without needing multiple specialized machines.

Whether it is for copper bar straightening or busbar grinding, the Multi-functional Copper Flat Bar Processing Equipment ensures that manufacturers can adapt quickly to production needs without sacrificing quality or speed. The ability to process various copper materials in one machine makes it a highly valuable investment for factories with diverse production lines.

4. Enhanced Surface Finish and Quality Control

The surface finish of copper materials is crucial for their performance in electrical and industrial applications. The Copper Flat Wire Straightening, Polishing, and Shearing Machine ensures a smooth, polished surface on copper flat wires, which is critical for minimizing friction and enhancing conductivity. By polishing the wire during the straightening and cutting process, this machine not only improves the wire’s aesthetic quality but also ensures that the copper maintains its functionality over time.

In addition, the Copper Busbar Straightening and Grinding Machine takes it a step further by not only straightening the busbar but also grinding its surface to an ideal smoothness. This smooth surface reduces the chances of electrical failures or performance issues, making it an essential tool in industries where copper busbars are used in electrical grids or transformers.

5. Cost-Effectiveness and Energy Efficiency

The operational cost savings from integrating straightening, grinding, and shearing functions into a single machine cannot be overstated. Machines like the Insulated Copper Flat Wire Straightening and Cutting Machine and the Flat Copper Wire Straightening and Cutting System significantly reduce the need for additional equipment. This leads to lower capital investment and operational expenses. In addition, since these machines are typically designed with energy efficiency in mind, manufacturers can achieve high output without consuming excessive amounts of energy.

The Multi-functional Copper Flat Bar Processing Equipment further adds to the cost-effectiveness of the production line. By combining multiple processes into one machine, manufacturers can reduce maintenance costs and improve machine utilization rates. Furthermore, fewer machines in operation mean lower power consumption and reduced environmental impact, which aligns with modern sustainability goals.

6. Scalability for Future Growth

As demand for copper materials increases in industries such as construction, automotive, and renewable energy, the ability to scale production efficiently becomes a key concern for manufacturers. The Copper Flat Wire Straightening, Polishing, and Shearing Machine and the Copper Busbar Straightening and Grinding Machine offer easy scalability options. These machines can handle increased production volumes with minimal adjustments to the existing setup, allowing manufacturers to quickly respond to market changes and production demands.

Additionally, the Flat Copper Wire Straightening and Cutting System is designed for continuous production, enabling manufacturers to scale their operations without downtime. The machine’s automated processes reduce the need for manual labor, thus allowing production lines to run more efficiently as volume increases.

7. Improved Safety and Ease of Operation

The automation of the Insulated Copper Flat Wire Straightening and Cutting Machine and other similar systems enhances not only productivity but also workplace safety. The risk of accidents and injuries is significantly reduced since the machines handle tasks such as cutting and grinding, which would otherwise require manual labor. Furthermore, the advanced safety features integrated into these machines, such as emergency stop buttons and automatic safety shutdowns, ensure that operators are protected from harm during the production process.

With intuitive controls and user-friendly interfaces, operators can quickly learn how to use these systems. The Multi-functional Copper Flat Bar Processing Equipment, for example, is designed with ease of operation in mind, reducing training time for new employees and ensuring smoother workflows across shifts.

Conclusion

The integration of straightening, grinding, and shearing machines in copper manufacturing processes brings a multitude of advantages, including improved precision, increased throughput, enhanced surface finish, cost-effectiveness, scalability, and safety. Machines like the Insulated Copper Flat Wire Straightening and Cutting Machine, Copper Busbar Straightening and Grinding Machine, Flat Copper Wire Straightening and Cutting System, Copper Flat Wire Straightening, Polishing, and Shearing Machine, and Multi-functional Copper Flat Bar Processing Equipment represent the future of efficient copper processing, offering manufacturers the tools they need to meet growing market demands while maximizing productivity and minimizing costs.

As the demand for high-quality copper products continues to rise, investing in these advanced machines will be essential for manufacturers looking to remain competitive in an increasingly fast-paced industry.