Breakthrough in Metal‑Casting Technology: Core Technology of the Ingot Casting Machine and Why It Surpasses Traditional Equipment

In the modern metal‑production landscape, the advent of the Copper Ingot Production Machine signals a major step change in how we cast primary metal form: when paired with an advanced Ingot Casting Machine, manufacturers are now able to produce copper ingot and aluminum ingot at scale, with improved quality, lower cost, and higher consistency. The modern Automatic Ingot Casting Machine in particular embodies this shift. This article examines the core technology underpinning the Ingot Casting Machine, explains why it is superior to traditional equipment, and outlines implications for the Copper Ingot Production Machine era of industrial manufacture.

The role of the Copper Ingot Production Machine in modern industry

The Copper Ingot Production Machine is increasingly the backbone of non‑ferrous metal casting operations. A Copper Ingot Production Machine typically includes an advanced Ingot Casting Machine unit, specifically tailored to produce copper ingot and aluminum ingot for downstream processing into wire, tubing, rods, and other forms. By combining melting, mold feeding, cooling and ejection into a streamlined line, the Copper Ingot Production Machine transforms molten copper or aluminium into uniform copper ingot and aluminum ingot blocks with minimal human intervention. Because the Copper Ingot Production Machine is often designed for high throughput, manufacturers now lean heavily on the integration of an Ingot Casting Machine into the broader cast‑house ecosystem, producing high-quality aluminum ingot alongside copper ingots.

Core technology of the Ingot Casting Machine

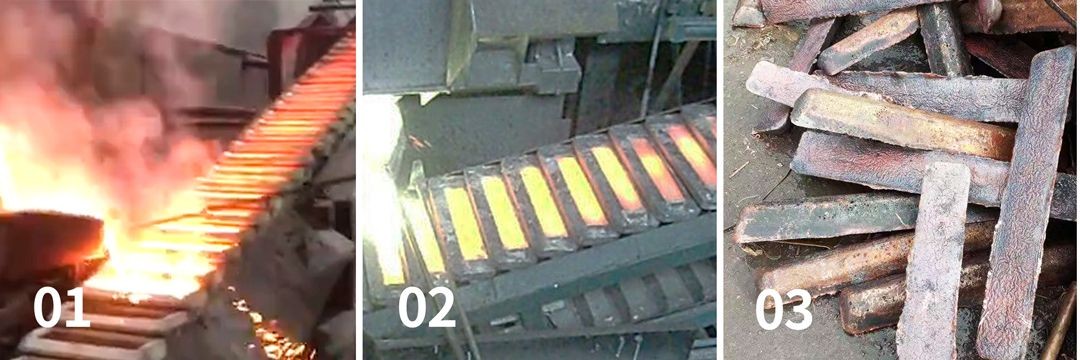

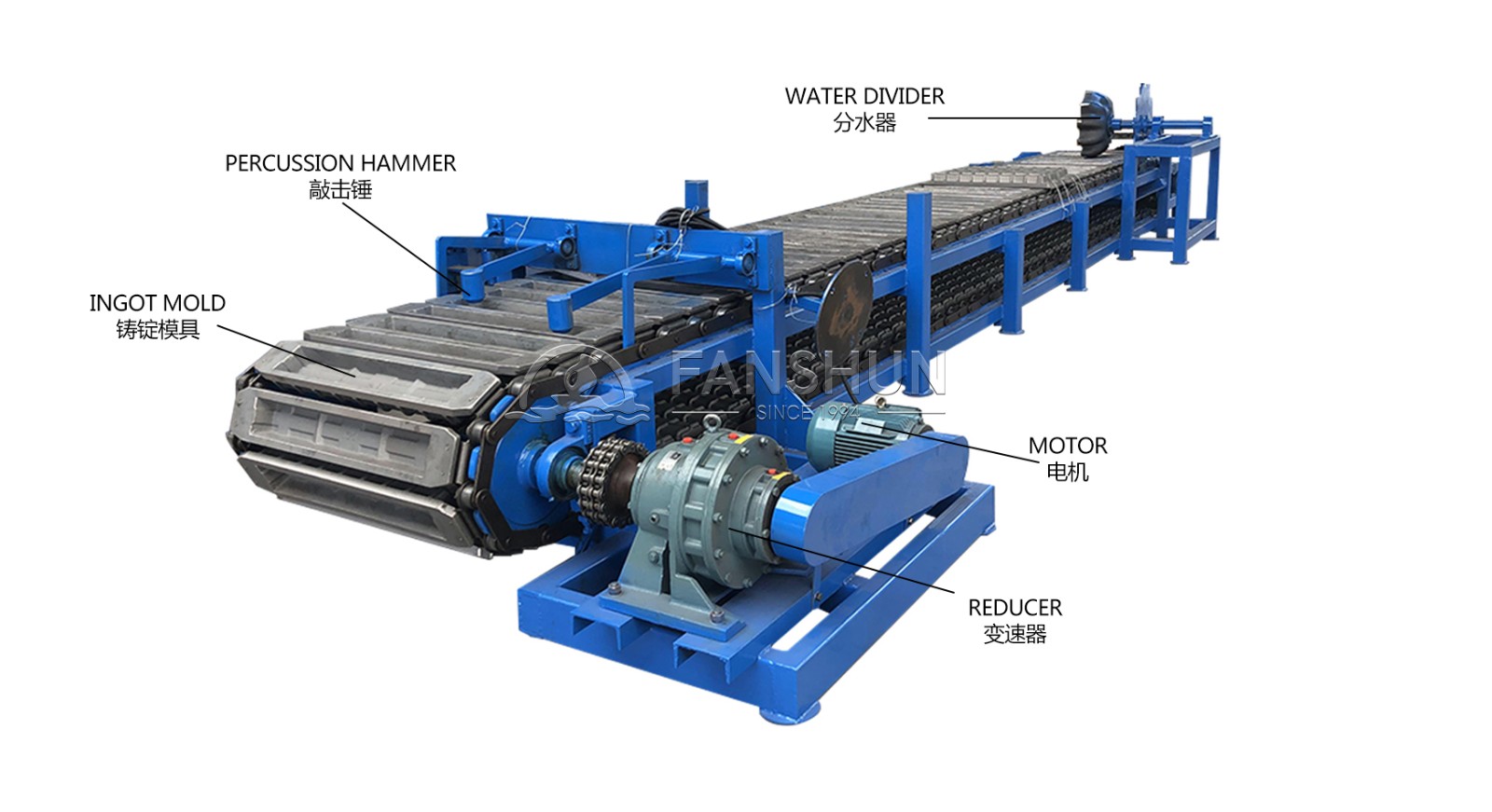

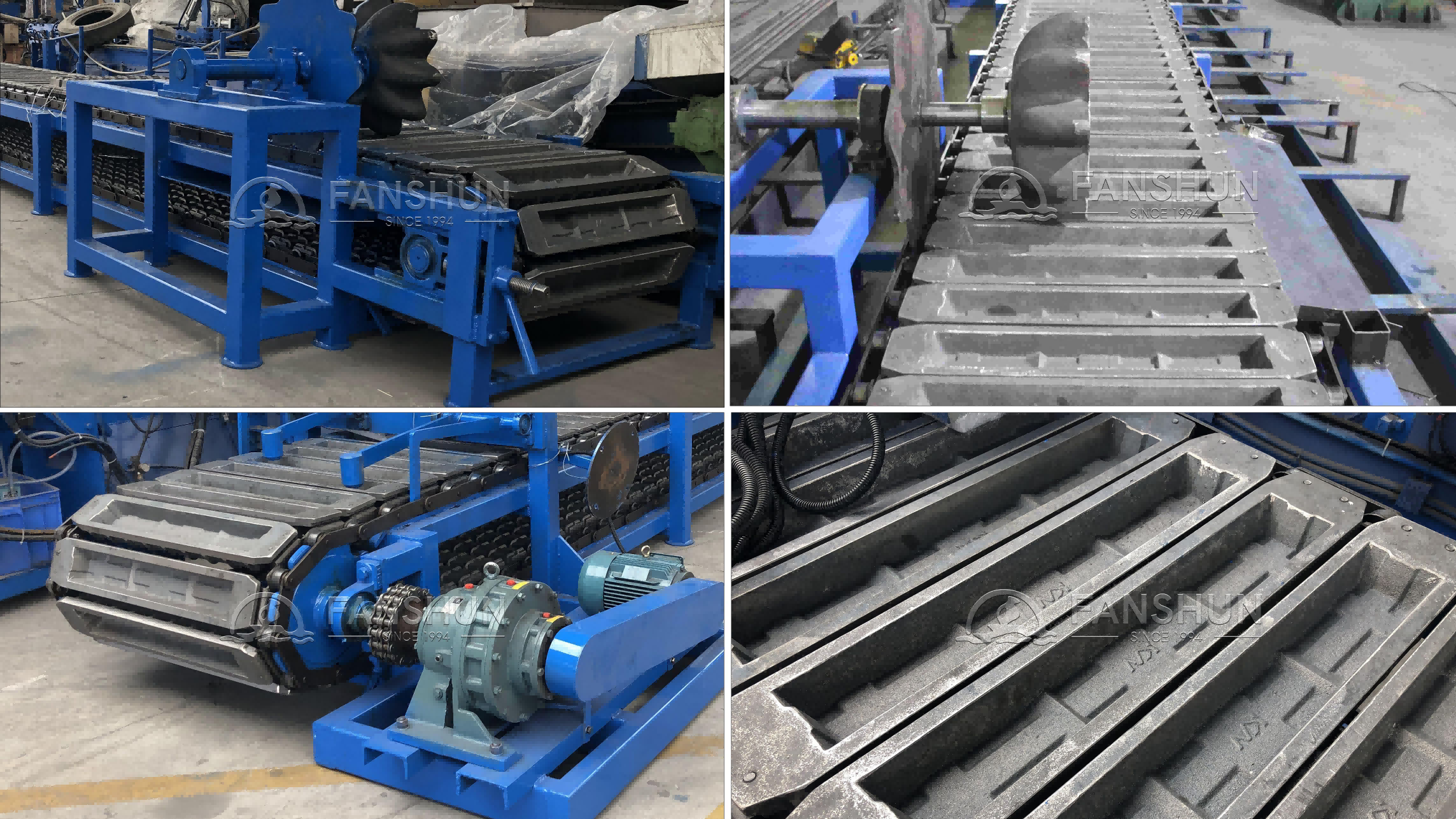

At the heart of the Ingot Casting Machine lies several interlocking technological advances. First, the molten metal is fed into precision molds via controlled pouring systems. The design ensures that both copper ingot and aluminum ingot solidify uniformly. As one analyst writes: “The casting line includes several devices: casting wheel, moulds’ casting chain conveyor, primary and secondary cooling system, coating unit, preheating system and knockout station.” The design of the mold, the cooling channels, and the automation of feed and ejection are central to achieving a high‑quality copper ingot or aluminum ingot.

Second, the Ingot Casting Machine integrates advanced automation and control systems. For instance, the fully automated ICS / Ingot Casting and Stacking unit can cast both pure aluminium ingot and foundry alloy ingots on a continuous basis, with the electrical automation control system managing every step of the process. A modern Automatic Ingot Casting Machine thus monitors temperature, feed rate, mold fill, and solidification in real time, enabling consistent production of copper ingot and aluminum ingot with minimal defects.

Third, the Ingot Casting Machine improves metal cleanliness, structure and yield. Improved solidification control ensures that both copper ingot and aluminum ingot are free from voids and inclusions. By optimizing the mold design, cooling rates, and metal flow, the Ingot Casting Machine creates ingots (whether copper ingot or aluminum ingot) with better internal soundness and more consistent grain structure. This enhances downstream performance, whether the block is a copper ingot used for extrusion or an aluminum ingot used for rolling, casting, or forging.

Fourth, the integration of the Ingot Casting Machine into a full production line (the Copper Ingot Production Machine) means the feeding from melting furnace, the pouring, the cooling, the stacking, and transport are all coordinated and often robotized. The “Automatic Ingot Casting Machine” concept emphasizes minimal manual intervention, higher throughput, and higher automation levels. Modern lines now produce hundreds of tons of aluminum ingot and copper ingot per day with unparalleled consistency.

Why the Ingot Casting Machine is better than traditional equipment

Compared with older, conventional equipment for ingot production, the modern Ingot Casting Machine (and by extension the Copper Ingot Production Machine with its Automatic Ingot Casting Machine capability) presents significant advantages:

Higher production efficiency: The integration of an Automatic Ingot Casting Machine means the continuous process of melting → mold fill → solidification → ejection → stacking can operate with minimal stoppage. Traditional methods often required manual ladling, manual mold handling, and slower cooling cycles. For copper ingot and aluminum ingot production, this means more tons per hour and less labor cost per ton.

Improved quality of ingots: As noted, the Ingot Casting Machine achieves more precise control over casting variables—mold fill, cooling rate, metal flow. For a copper ingot or aluminum ingot, that means fewer shrinkage cavities, fewer inclusions, and more uniform grain structure. Because the Copper Ingot Production Machine uses the Ingot Casting Machine’s precision, manufacturers see fewer downstream defects in wire, extrusion, rolling or other processes, and higher quality aluminum ingot output.

Better reproducibility and yield: The automation built into an Automatic Ingot Casting Machine ensures that each block—whether a copper ingot or an aluminum ingot—meets weight, dimension, and structural targets. The Ingot Casting Machine’s feedback systems reduce variation, which means less scrap, less re‑work, and higher usable yield per melt.

Lower energy and operational cost: Modern Ingot Casting Machine designs incorporate efficient cooling systems, optimized mold designs, and automation that reduces downtime. Because the Copper Ingot Production Machine uses these enhancements, the cost per unit of copper ingot or aluminum ingot produced drops. Traditional equipment typically had older, less efficient cooling or mold designs and required higher labor intensity.

Reduced human error and improved safety: Because an Automatic Ingot Casting Machine handles many steps automatically, the risk of operator mistakes (mis‑pouring, mold mishandling, inconsistent cooling) decreases. That means fewer defects in copper ingot or aluminum ingot output, and better safety in the cast‑house environment.

Scalability and flexibility: The Ingot Casting Machine can be adapted to different ingot sizes, shapes, and alloys. For a Copper Ingot Production Machine, that means the same line can handle variations in copper alloy, different ingot geometries, and multiple grades of aluminum ingot. Traditional equipment may have been fixed-size, less flexible, and slower to adapt when product specifications changed.

Key features in the real world

In practice, if you examine a modern Copper Ingot Production Machine line, you’ll see the Ingot Casting Machine at center stage — for both copper ingot and aluminum ingot operations:

The Automatic Ingot Casting Machine feeds molten metal (copper or aluminium) from a holding furnace into a precision mold via a casting wheel or chain conveyor. The molten metal is poured in a controlled way to minimize turbulence, splashing, and oxide entrapment, ensuring that both copper ingot and aluminum ingot are consistently high quality.

The mold design includes internal cooling channels, water cooling jackets, and often dynamic features, ensuring optimal solidification for aluminum ingot and copper ingot alike.

Sensors and control systems monitor temperature, mold fill, solidification front, ejection timing, and stacking. This data feedback ensures that each copper ingot and aluminum ingot meets specification.

After casting, the ingots are automatically ejected, transferred, cooled further as needed, and stacked by robotic stacker and strapper systems. The Copper Ingot Production Machine thus becomes a continuous line of high throughput, producing both aluminum ingot and copper ingot with unmatched precision.

Strategic benefits for the metal industry

Given the improvements in the Ingot Casting Machine and its role within the Copper Ingot Production Machine framework, the industry-wide benefits are substantial:

Reduced total cost of ownership: Because the Automatic Ingot Casting Machine reduces labor, scrap, re-work, and energy usage, the cost per ton of copper ingot or aluminum ingot falls.

Faster capacity ramp-up: Manufacturers needing to scale production of copper ingot or aluminum ingot can install a dedicated Copper Ingot Production Machine built around a state-of-the-art Ingot Casting Machine and go from melt to ingot with minimal manual bottlenecks.

Better downstream product performance: Higher quality ingots (copper and aluminium) yield improved downstream results—less defects in extrusion, drawing, rolling, forging, or casting. This means customers of ingot producers benefit from consistent aluminum ingot and copper ingot quality.

Sustainability and efficiency gains: With better yield, fewer rejects, less re-melting required, less energy wasted, the Automatic Ingot Casting Machine helps support greener operations.

Flexibility and future proofing: The Ingot Casting Machine can be configured for different alloys, different ingot sizes (for both copper and aluminum ingot). A Copper Ingot Production Machine with a flexible Ingot Casting Machine is well positioned for evolving market demands.

Conclusion

In conclusion, the Ingot Casting Machine represents the core technology behind modern cast-house operations for non-ferrous metals. Within the broader Copper Ingot Production Machine framework, the Automatic Ingot Casting Machine provides higher efficiency, better ingot quality (whether a copper ingot or aluminum ingot), lower cost, improved yield, and greater flexibility compared to traditional equipment. For metal producers looking to stay competitive, adopt new technologies, and meet rising demand, investing in the Ingot Casting Machine and leveraging the benefits it offers is no longer optional—it is imperative.

As the industry shifts from older, labor-intensive, less precise ingot production methods into fully automated, high-throughput lines, the role of the Copper Ingot Production Machine and the Ingot Casting Machine will continue to gain prominence. When producers effectively harness the capabilities of the Automatic Ingot Casting Machine, they will unlock superior output of copper ingot and aluminum ingot, enhance downstream product quality, reduce cost, and position themselves for the next decade of metal-casting innovation.