What’s the Secret Behind the Vibrating Magnetic Filter’s Powerful Iron Removal?

In modern metal production and industrial purification, one question stands out: What’s the secret behind the Vibrating Magnetic Filter’s powerful iron removal? The answer lies in a new generation of magnetic filter technology—an innovation that combines vibration and strong magnetic fields to capture every trace of iron impurity.

Today, more and more factories are adopting magnetic filter systems to ensure their products remain free from contamination. These systems are not only powerful but also incredibly efficient. By using magnetic filtration, they trap even microscopic iron particles that traditional mechanical filters fail to remove. A magnetic filter system provides continuous protection, cleaner materials, and longer machine life.

One of the fastest-growing applications of this technology is the boiler magnetic filter. In heating systems, iron oxide and rust often accumulate inside pipes and boilers, reducing efficiency and causing damage. Installing a boiler magnetic filter prevents this by capturing ferrous sludge and magnetic debris before they circulate through the system. Over time, a boiler magnetic filter can drastically cut maintenance costs and extend boiler lifespan.

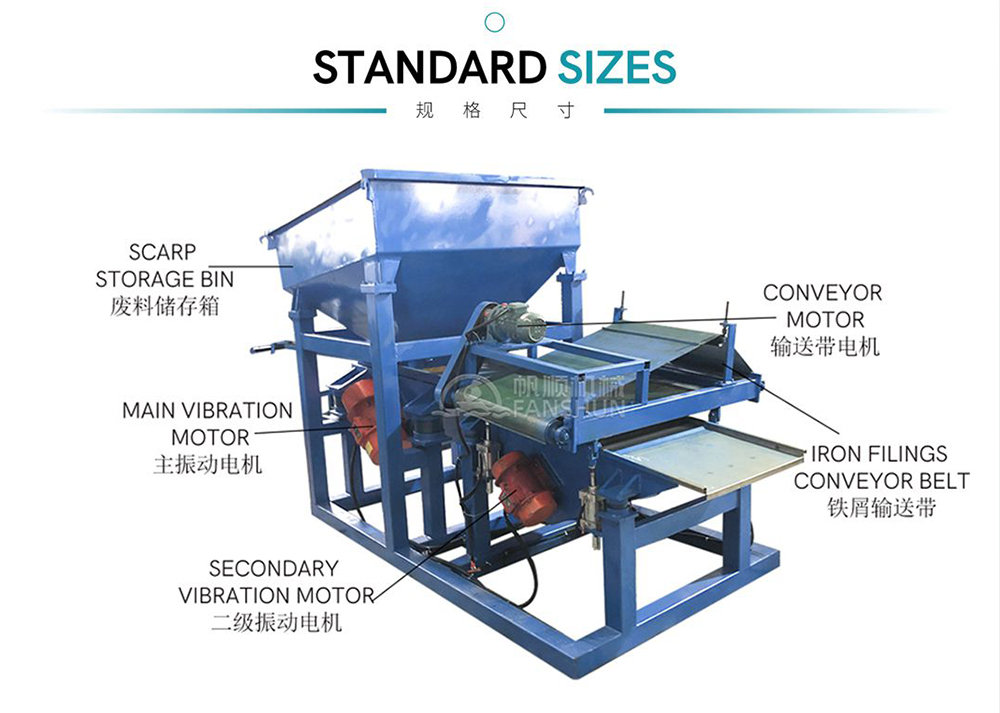

The combination of vibration and magnetic filtration makes the Vibrating Magnetic Filter unique. The vibration helps shake loose any collected impurities, while the magnetic field continuously attracts iron particles. This dual action keeps the magnetic filter system operating at full efficiency. In high-precision metal industries—such as brass rod production or copper tube manufacturing—this kind of magnetic filtration ensures that every finished product is smooth, pure, and defect-free.

Many engineers consider the magnetic strainer filter an essential part of modern production lines. Unlike conventional strainers, a magnetic strainer filter doesn’t rely solely on mesh or pressure. Instead, it uses magnetic attraction to separate contaminants and prevent buildup. Because the magnetic strainer filter has no disposable parts, it offers a cleaner, more sustainable solution for long-term use.

A typical magnetic filter system can be installed in both liquid and gas pipelines, offering flexibility for diverse industries—from metallurgy and mining to food processing and energy plants. With magnetic filtration, each drop of fluid or stream of air is purified continuously, reducing wear on pumps and valves. The more advanced systems include vibrating mechanisms, ensuring the magnetic strainer filter remains unclogged during long runs.

For metalworking companies, adopting boiler magnetic filters and magnetic filter systems is a game changer. Boilers and heat exchangers equipped with these technologies stay cleaner and more efficient for years. The boiler magnetic filter effectively stops the circulation of black iron sludge, one of the most common causes of system inefficiency. Pairing a boiler magnetic filter with an automated magnetic filter system guarantees top-tier protection and smoother energy flow.

Meanwhile, magnetic filtration continues to evolve beyond heating applications. In molten metal processing, a magnetic strainer filter removes iron impurities before casting or extrusion. The result is higher product quality and fewer defects. In hydraulic and lubrication systems, magnetic filtration prevents fine metal dust from damaging bearings and seals. The same principle applies in chemical, pharmaceutical, and recycling plants—anywhere iron contamination must be controlled.

Another advantage of magnetic filtration is environmental sustainability. The captured particles can be recycled, and no disposable filter media are needed. This makes the magnetic filter system an eco-friendly investment for forward-thinking manufacturers. When paired with vibration, the magnetic strainer filter becomes nearly self-cleaning, reducing downtime and manual labor.

In the heating sector, the boiler magnetic filter has become a must-have component for both residential and industrial systems. It ensures consistent heat output, cleaner water circulation, and lower energy consumption. Many engineers now design entire magnetic filter systems around boilers, combining boiler magnetic filters with advanced pumps and smart control systems for maximum efficiency.

The secret behind the Vibrating Magnetic Filter’s iron removal power is simple yet sophisticated: a synergy between magnetic science and vibration engineering. Together, they make magnetic filtration faster, cleaner, and more effective than ever before. Whether installed as a boiler magnetic filter, a magnetic filter system, or a magnetic strainer filter, this technology guarantees longer equipment life, higher purity, and smoother industrial performance.

As industries continue to push for higher standards of cleanliness and efficiency, magnetic filtration will remain at the heart of innovation. From heavy metal foundries to precision manufacturing plants, the magnetic filter system is not just a piece of equipment—it’s the cornerstone of the next generation of clean, sustainable production.