Why Are More and More Factories Choosing Metal Chip Briquetting Machines?

In recent years, industrial manufacturers across various sectors have been increasingly turning to metal briquetting machines as a solution to handle their growing volumes of metal scrap. This trend is not just a passing wave—it's a direct response to the mounting pressure on manufacturers to optimize efficiency, reduce waste, and enhance sustainability. The surge in demand for briquetting machines, especially the hydraulic briquette press, highlights how modern technologies are transforming waste management in manufacturing.

The Rise of the Metal Briquetting Machine

A metal briquetting machine is designed to compress metal chips, shavings, and powder into dense, cylindrical or block-shaped briquettes. These machines help convert loose, hard-to-handle materials into valuable products that are easy to store, transport, and remelt. Unlike traditional disposal methods, which can be costly and environmentally damaging, using a briquette press machine significantly reduces volume and allows factories to recover the value of metal. This makes the metal briquetting machine a valuable asset for any metalworking operation.

One of the primary reasons more factories are investing in briquette press machine systems is the immediate cost savings. By compacting scrap into briquettes, manufacturers can reduce transportation and storage costs while increasing furnace efficiency during remelting. The compacted form also leads to higher yield and reduced oxidation losses. More importantly, a hydraulic briquette press ensures that the briquetting process is efficient and consistent. A metal briquetting machine helps streamline this entire process.

How the Briquette Press Works

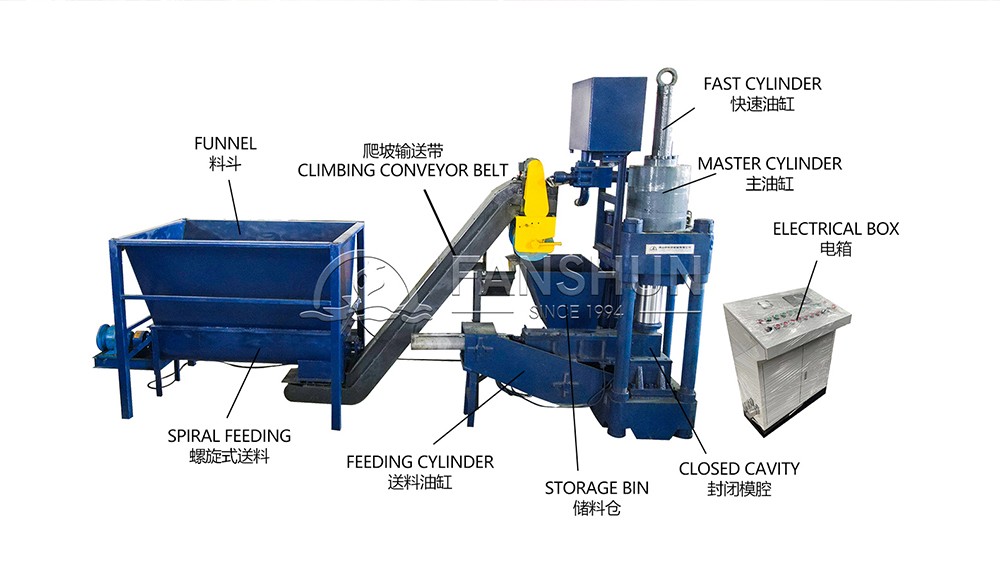

A briquette press machine typically operates using hydraulic force. The hydraulic briquette press is especially popular due to its high pressure, consistent performance, and ability to handle a wide variety of metal scraps—ranging from aluminum and copper to steel and iron. The working principle involves feeding loose metal chips into a hopper, which are then compressed by a hydraulic ram into a solid briquette. The resulting product is easy to handle and has high density. With a hydraulic briquette press, even fine particles can be effectively compacted into reusable material. The metal briquetting machine ensures uniform compression throughout the cycle.

The use of a hydraulic briquette press ensures uniform size and shape, which is crucial for downstream processes like melting or resale. These machines are known for their durability, low maintenance, and energy efficiency. As a result, more factories are opting for briquette press machines equipped with advanced hydraulic briquette press systems to improve their operations. A high-efficiency metal briquetting machine guarantees performance and reliability.

Environmental and Economic Benefits

Factories that deploy metal briquetting machines not only save money but also make significant contributions to environmental protection. Briquetting reduces the need for landfill disposal, lowers emissions during transportation, and minimizes fluid leakage often found in loose chips. Furthermore, using a briquette press machine allows recovery of expensive coolants and cutting oils, which can be reused in production. In many cases, a hydraulic briquette press becomes essential for managing metal waste in an eco-friendly way. A metal briquetting machine adds significant long-term value through waste minimization.

The briquetting machine also plays a pivotal role in closed-loop manufacturing systems. Instead of treating metal scrap as waste, manufacturers use the metal briquetting machine to reintegrate valuable material back into the production cycle. This creates a circular economy where resources are conserved and waste is minimized. A properly designed briquette press machine fitted with a reliable hydraulic briquette press can make this process seamless. By integrating a metal briquetting machine, factories can turn waste into profit.

Widespread Adoption Across Industries

From automotive and aerospace to machining workshops and metal recycling plants, the adoption of the briquette press machine is gaining momentum. Each sector finds unique advantages in integrating a hydraulic briquette press into their production line. For instance, aluminum processors benefit from reduced dross formation, while steel and cast iron manufacturers see improved furnace efficiency thanks to a properly calibrated briquette press machine. The role of the metal briquetting machine continues to grow across sectors.

Moreover, the scalability of the briquetting machine means it can serve both large-scale industrial operations and small fabrication shops. With customizable configurations and advanced automation features, these machines are tailored to meet diverse needs. Whether small or large, each briquette press machine benefits from incorporating a durable hydraulic briquette press. This is especially true for operations that rely heavily on a metal briquetting machine for daily production.

Choosing the Right Briquette Press

When selecting a briquette press, factories consider several factors such as material type, throughput, size of the briquette, and automation level. A good metal briquetting machine should be able to handle mixed metal types, deliver consistent pressure, and offer user-friendly controls. An effective briquette press machine paired with a high-performance hydraulic briquette press makes all the difference. Every detail matters when choosing the right metal briquetting machine.

Modern briquette press machines come equipped with intelligent monitoring systems, safety features, and integration capabilities with existing factory automation. This ensures not only efficiency but also worker safety and long-term performance. These upgrades are often centered around the hydraulic briquette press technology. Integration of a metal briquetting machine into existing systems enhances operational capacity.

Real-World Case Studies

Numerous manufacturers have shared their success stories after implementing briquetting machines. One automotive parts manufacturer reported a 35% reduction in storage space and a 20% increase in remelting efficiency after installing a hydraulic briquette press. Another machining workshop cited a dramatic decrease in coolant purchase after switching to a briquette press machine, as they could now recover and reuse fluids trapped in loose chips. These stories underscore the value of a high-efficiency briquette press machine with hydraulic briquette press functionality. For both examples, the metal briquetting machine played a crucial role.

These real-world applications underscore the transformative impact of the briquette press in modern manufacturing. As more businesses experience success, the reliance on briquette press machines and especially hydraulic briquette press solutions continues to grow. The metal briquetting machine is now central to many operational strategies.

Future Outlook

As regulations on waste disposal become stricter and material costs continue to rise, the use of metal briquetting machines is expected to become standard practice in manufacturing. Innovations in briquette press machine technology—such as real-time diagnostics, remote control, and predictive maintenance—will further boost adoption. Among these innovations, the evolution of the hydraulic briquette press remains a key driver of advancement. The metal briquetting machine will become even more integral with these upgrades.

The briquetting machine is not just a piece of equipment; it’s a strategic investment in efficiency, sustainability, and competitiveness. Every briquette press machine fitted with a powerful hydraulic briquette press system serves as a cornerstone of future-ready manufacturing. And at the center of this movement is the increasingly vital metal briquetting machine.

Conclusion

The question “Why are more and more factories choosing metal chip briquetting machines?” is best answered by the overwhelming benefits these systems provide. With undeniable advantages in cost savings, environmental impact, and operational efficiency, briquetting machines, particularly the hydraulic briquette press, are reshaping how industries manage metal scrap. As awareness grows and technology evolves, the briquette press machine will continue to be an indispensable tool in modern manufacturing. A high-quality metal briquetting machine remains one of the smartest investments for any forward-thinking facility.

Whether you're a factory manager looking to optimize your production line or a recycler aiming to boost profits, there's no better time to invest in a metal briquetting machine. It’s clear that the future of metal waste management lies in the power of the briquette press machine and the versatility of the hydraulic briquette press.