Why Are More and More Manufacturers Choosing a Power-Frequency Scrap Copper Die Casting Furnace?

In recent years, the metal processing industry has witnessed a significant shift in technology preferences. More and more manufacturers are choosing a Power Frequency furnace for processing scrap copper, and the reasons are clear. The modern die casting furnace market demands not only precision but also efficiency, safety, and environmental responsibility. This is why the copper melting furnace equipped with High Efficiency Melting technology is becoming a top choice worldwide.

The rise in popularity of the Power Frequency furnace is closely linked to its ability to handle scrap copper with high precision. Unlike traditional furnaces, a Power Frequency furnace allows for uniform heating, minimizing metal loss and maximizing yield. When paired with a state-of-the-art die casting furnace, manufacturers can achieve superior High Efficiency Melting for various types of scrap copper, whether from industrial production or recycled materials.

One of the core advantages of using a copper melting furnace in combination with Power Frequency furnace technology is its energy efficiency. The High Efficiency Melting process ensures that heat is delivered directly and evenly, reducing fuel consumption and shortening melting cycles. Manufacturers processing scrap copper report up to 30% faster melting times and lower operational costs compared to conventional methods. This efficiency gain is one of the main reasons why more companies are choosing a die casting furnace integrated with Power Frequency furnace systems.

Environmental compliance is another key factor driving the adoption of Power Frequency furnace technology. Handling scrap copper in a traditional furnace often results in excessive emissions and energy waste. In contrast, a copper melting furnace designed for High Efficiency Melting minimizes harmful emissions while maintaining consistent molten metal quality. For manufacturers committed to sustainable practices, choosing a die casting furnace with Power Frequency furnace capability is both a business and environmental decision.

Moreover, the versatility of a Power Frequency furnace is particularly appealing. Manufacturers can use the same copper melting furnace to process different types of scrap copper, including bare copper, brass, and other alloys. This flexibility is enhanced by the furnace's precise temperature control, which ensures optimal High Efficiency Melting regardless of material composition. By integrating a die casting furnace with Power Frequency furnace technology, production lines can achieve higher output and lower energy consumption, making it a cost-effective solution for large-scale operations.

Maintenance and operational simplicity also contribute to the rising preference for Power Frequency furnace systems. Traditional furnaces often require extensive labor for monitoring and adjustments, especially when melting scrap copper. In contrast, a modern copper melting furnace with High Efficiency Melting capabilities allows operators to maintain stable performance with minimal intervention. This reliability has made die casting furnace systems with Power Frequency furnace integration a favorite among manufacturers seeking both efficiency and consistency.

Safety is another critical consideration. Handling molten scrap copper in conventional furnaces poses risks of overheating, spillage, and uneven melting. The Power Frequency furnace, combined with a die casting furnace, reduces these risks through precise thermal management. With High Efficiency Melting, manufacturers achieve faster, cleaner, and safer processing of scrap copper. These improvements in operational safety have further reinforced the choice of copper melting furnace systems worldwide.

In addition, the economic benefits of using a Power Frequency furnace cannot be overlooked. With rising energy costs, manufacturers are seeking ways to reduce consumption while maximizing output. High Efficiency Melting technology in modern copper melting furnace systems allows businesses to achieve these goals. By effectively processing scrap copper in a die casting furnace, companies can improve yield, reduce waste, and shorten production cycles, ultimately improving profitability.

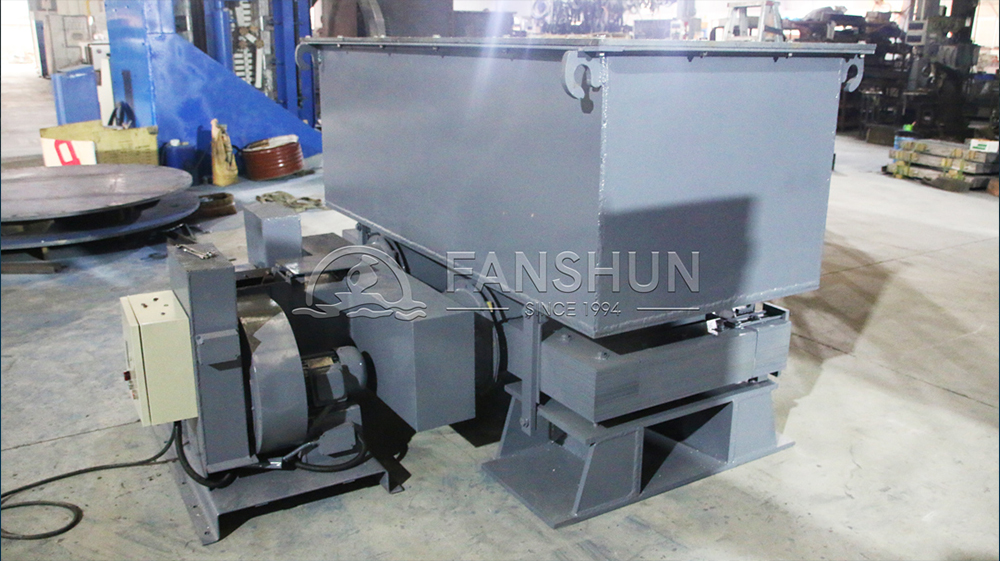

The technological innovation behind Power Frequency furnace systems has also contributed to their widespread adoption. Advanced features such as digital control, automated feeding of scrap copper, and real-time monitoring ensure that the die casting furnace operates at peak High Efficiency Melting performance. Manufacturers can now produce high-quality castings with precise specifications, reducing defects and improving overall production quality. The combination of a copper melting furnace and Power Frequency furnace technology represents a modern approach to efficient, reliable, and environmentally responsible scrap copper processing.

In conclusion, the growing trend of choosing a Power Frequency furnace for scrap copper processing is driven by multiple factors: energy efficiency, environmental benefits, operational safety, versatility, and economic advantages. When integrated into a die casting furnace, the copper melting furnace equipped with High Efficiency Melting technology provides manufacturers with a reliable, high-performance solution. As the metal industry continues to innovate, it is clear why more and more manufacturers are investing in Power Frequency furnace systems for their scrap copper processing needs. The future of efficient and sustainable metal casting is closely tied to the widespread adoption of High Efficiency Melting in modern die casting furnace operations.