Why Are More and More Manufacturers Choosing Automatic Feeding Double-Rod Drawing Machines?

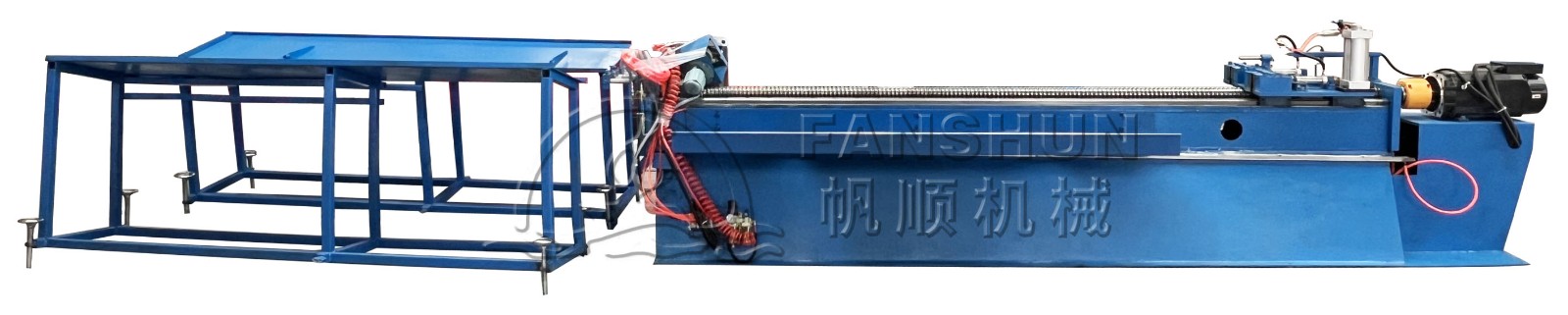

In recent years, the Automatic Feeding Double Bar Drawing Machine has emerged as a cornerstone in the metal processing and manufacturing industry. With production demands rising and efficiency becoming a top priority, manufacturers are turning to smarter, faster, and more cost-effective solutions. The Automatic Feeding Double Bar Drawing Machine is at the heart of this industrial evolution, integrating the functions of a Drawing Machine, Bar Drawing Machine, Pattern Drawing Machine, and Automatic Feeder Drawing Machine into a single high-performance system.

The Rise of the Automatic Feeding Double Bar Drawing Machine

Why are so many companies transitioning to the Automatic Feeding Double Bar Drawing Machine? The answer lies in its unmatched productivity, labor-saving automation, and enhanced product consistency. Traditional Drawing Machines required significant manual effort and were limited to single-bar operation. In contrast, this next-generation machine uses advanced automation to feed, grip, and draw two bars simultaneously—cutting production time nearly in half.

In factories around the world, this dual-drawing innovation is transforming the way raw materials are processed. The Automatic Feeder Drawing Machine automates bar feeding with precision, ensuring continuous operation without interruption. This has proven especially useful in high-volume manufacturing environments.

Automatic Feeder Drawing Machine: Automation at Its Best

One of the key features of the Automatic Feeder Drawing Machine is its intelligent control system. It adjusts feed speeds, monitors bar tension, and controls drawing force in real time. This reduces wear and tear on the equipment, increases the life span of drawing dies, and enhances the surface quality of bars.

The Automatic Feeder Drawing Machine eliminates the need for manual feeding, which not only lowers labor costs but also reduces the risk of workplace injury. Safety, reliability, and simplicity in operation are what attract modern manufacturers to this system.

Why the Bar Drawing Machine Stands Out

The Bar Drawing Machine has long been a core tool in shaping metal bars. What makes the new Automatic Feeding Double Bar Drawing Machine revolutionary is that it doesn’t replace the traditional Bar Drawing Machine—it upgrades it. Dual-bar processing means you get the performance of two machines in one footprint, reducing space requirements on the production floor.

Each Bar Drawing Machine process is now more refined. From entry guides to outlet sizing, the control of bar shape and pattern is more precise than ever before. This consistency ensures fewer defects, higher material yield, and overall better quality control.

The Role of the Drawing Machine in High-Speed Operations

A traditional Drawing Machine performs well for general purposes, but in today’s fast-paced production cycles, speed and automation are critical. That’s where the Automatic Feeding Double Bar Drawing Machine shines. It retains all the benefits of a conventional Drawing Machine, while drastically reducing downtime through integrated automation systems.

Every Drawing Machine in this series is designed with efficiency in mind. Servo motors, tension control, and hydraulic clamping all contribute to stable and uniform operation. And since these machines are designed to handle a wide range of bar diameters, they’re perfect for diverse product lines.

Precision with the Pattern Drawing Machine Feature

One often overlooked feature is the ability of this system to act as a Pattern Drawing Machine. That means it doesn’t just pull bars into shape—it can also imprint precision surface patterns required by some industries like architectural, automotive, and electrical components. The Pattern Drawing Machine component helps in adding texture or surface treatment, elevating both functionality and aesthetic appeal.

Thanks to its integration with the Automatic Feeder Drawing Machine, the Pattern Drawing Machine operates in perfect sync, ensuring that the patterns are uniform and aligned across both bars. This dual capability has been especially popular in the decorative metal industry.

In fact, the Pattern Drawing Machine aspect of the Automatic Feeding Double Bar Drawing Machine is one of the top reasons why decorative hardware and premium pipe manufacturers are adopting it rapidly. With greater pattern consistency, deeper etching control, and automatic alignment, the Pattern Drawing Machine functionality stands out.

More importantly, users have discovered that the Pattern Drawing Machine not only improves product value but also reduces the need for additional post-processing. By producing finished textures directly in the draw cycle, the Pattern Drawing Machine saves time and cost.

Engineers appreciate how customizable the Pattern Drawing Machine settings are. Different rollers, textures, and depths can be pre-configured in the Pattern Drawing Machine interface, making it suitable for batch production and fast changeovers. Repeatability, precision, and design flexibility are key strengths of every Pattern Drawing Machine integrated into these systems.

The Pattern Drawing Machine is not a secondary function—it’s a driving force of innovation. For many buyers, the inclusion of a high-quality Pattern Drawing Machine module is what justifies the upgrade from older machines.

Real-World Impact: Efficiency, Quality, and ROI

In case studies across Europe and Asia, the Automatic Feeding Double Bar Drawing Machine has shown an average productivity increase of over 40%. Downtime has dropped by 60%, and labor requirements were reduced by 50%. These impressive numbers explain why manufacturers from various sectors—construction, electronics, plumbing, and transportation—are choosing this advanced solution.

Companies report not only higher efficiency but also a noticeable improvement in product quality. Since each Bar Drawing Machine within the unit can operate independently or in tandem, versatility is unmatched. You can switch between single-bar or dual-bar modes depending on your needs.

The Future of Drawing Technology

Looking ahead, the Automatic Feeding Double Bar Drawing Machine represents the future of smart manufacturing. With Industry 4.0 and the trend toward intelligent factories, this machine is perfectly aligned with modern digital control systems. Integration with ERP and MES systems is seamless, giving production managers real-time data on machine performance, output, and maintenance needs.

The demand for multi-functional machines like the Automatic Feeder Drawing Machine and Pattern Drawing Machine is expected to grow rapidly. As companies face increasing pressure to reduce costs and increase efficiency, smart investments in automation will become essential.

In conclusion, the shift toward the Automatic Feeding Double Bar Drawing Machine is not just a trend—it’s a strategic move driven by measurable results. By combining the power of a Drawing Machine, Bar Drawing Machine, Pattern Drawing Machine, and Automatic Feeder Drawing Machine, manufacturers gain a competitive edge in quality, speed, and cost-effectiveness.

No matter your industry, if you're looking to streamline production and stay ahead in today’s market, it’s time to ask: Is your facility ready for the Automatic Feeding Double Bar Drawing Machine?