Why Are More and More Manufacturers Choosing Copper Strip Horizontal Continuous Casting Lines? Key Technical Highlights Revealed

SECTION 1 – GLOBAL MARKET MOMENTUM

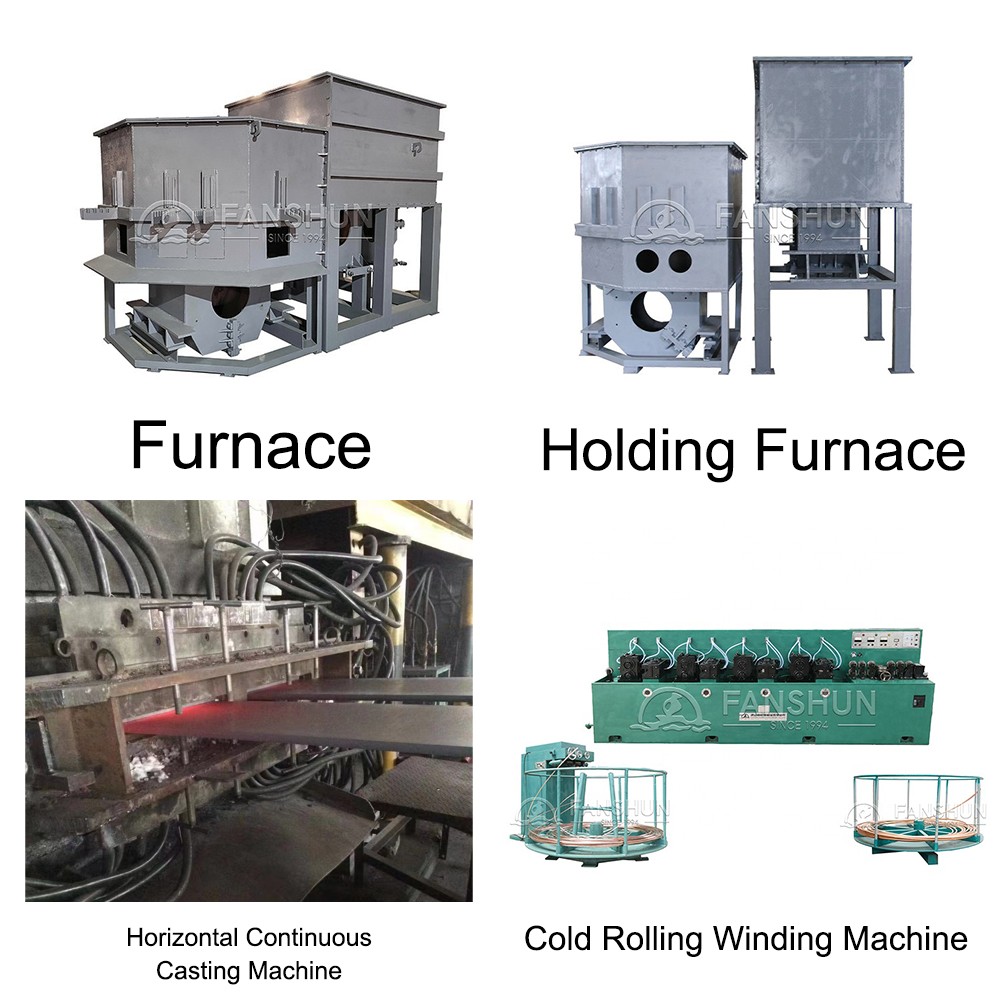

As global manufacturers increase their demand for high-precision metal materials, the copper strip, flat copper strip, thin copper strips, copper strip roll, and Horizontal Continuous Casting Copper Strip technologies are reshaping competitive advantages in the industry.

Factories worldwide report that adopting copper strip systems integrated with flat copper strip solutions allows them to achieve consistent quality across thin copper strips while maintaining stable copper strip roll performance using Horizontal Continuous Casting Copper Strip equipment.

Driven by modernization needs, the market shows a clear shift toward copper strip upgrades, where flat copper strip innovations improve efficiency, thin copper strips enhance product flexibility, copper strip roll handling becomes easier, and Horizontal Continuous Casting Copper Strip reliability continues to rise.

Industry analysts highlight that companies selecting copper strip solutions based on flat copper strip engineering can better optimize thin copper strips production workflows, improve copper strip roll stability, and guarantee Horizontal Continuous Casting Copper Strip yield.

Demand forecasts indicate that copper strip utilization aligned with flat copper strip standards ensures consistent thin copper strips output, smoother copper strip roll logistics, and wider adoption of Horizontal Continuous Casting Copper Strip technologies.

Market studies confirm that manufacturers prefer copper strip manufacturing with flat copper strip precision because high-grade thin copper strips improve energy efficiency, copper strip roll durability increases, and Horizontal Continuous Casting Copper Strip lines deliver long-term production stability.

SECTION 2 – TECHNOLOGY PERFORMANCE

Technical improvements in the copper strip sector show that combining flat copper strip design with advanced thin copper strips metallurgy significantly enhances copper strip roll uniformity through modern Horizontal Continuous Casting Copper Strip processes.

Engineers note that copper strip quality becomes more predictable when flat copper strip geometry is controlled, enabling thin copper strips to maintain structural integrity as the copper strip roll moves through Horizontal Continuous Casting Copper Strip machinery.

Performance testing demonstrates that optimized copper strip surfaces and improved flat copper strip shaping reduce defects in thin copper strips, maintain stable copper strip roll tension, and increase throughput in Horizontal Continuous Casting Copper Strip operations.

Research centers confirm that precise copper strip cooling systems help maintain flat copper strip thickness stability, support uniform thin copper strips, ensure smooth copper strip roll feeding, and strengthen the consistency of Horizontal Continuous Casting Copper Strip outputs.

Field reports show that refining copper strip metallurgy and enhancing flat copper strip accuracy allow better thin copper strips elongation, more reliable copper strip roll winding, and superior reliability from Horizontal Continuous Casting Copper Strip lines.

Experts agree that breakthrough copper strip temperature-control strategies combined with flat copper strip surface optimization create higher-grade thin copper strips, smoother copper strip roll production, and more robust Horizontal Continuous Casting Copper Strip capabilities.

SECTION 3 – COST & ENERGY ADVANTAGES

Economic analyses reveal that adopting copper strip production using flat copper strip configurations lowers operational costs, reduces waste in thin copper strips, extends copper strip roll lifespan, and increases overall Horizontal Continuous Casting Copper Strip efficiency.

Manufacturers point out that streamlined copper strip workflows built around flat copper strip precision reduce scrap rates across thin copper strips, reduce downtime in copper strip roll changeovers, and boost Horizontal Continuous Casting Copper Strip uptime.

Production managers say the latest copper strip systems aligned with flat copper strip mechanics improve heat transfer on thin copper strips, reduce copper strip roll variability, and minimize energy loss in Horizontal Continuous Casting Copper Strip stations.

Cost-saving simulations prove that integrating copper strip casting with flat copper strip engineering enhances productivity of thin copper strips, cuts copper strip roll replacement frequency, and strengthens resource efficiency in Horizontal Continuous Casting Copper Strip plants.

Industrial reports show that energy-optimized copper strip facilities configured for flat copper strip reduction lower temperatures for thin copper strips, enhance copper strip roll consistency, and deliver major power savings in Horizontal Continuous Casting Copper Strip environments.

Financial experts conclude that operational savings from improved copper strip setups using flat copper strip methods bring significant returns when producing thin copper strips, handling copper strip roll inventories, and running Horizontal Continuous Casting Copper Strip lines continuously.

SECTION 4 – QUALITY & RELIABILITY

Quality inspectors confirm that modern copper strip inspection systems paired with flat copper strip controls help ensure stronger thin copper strips, reduce surface variance in copper strip roll output, and elevate the dependability of Horizontal Continuous Casting Copper Strip manufacturing.

Customers report that strict copper strip tolerances and refined flat copper strip machining greatly improve durability across thin copper strips, making copper strip roll shipments more stable and enhancing the international reputation of Horizontal Continuous Casting Copper Strip suppliers.

ISO audits indicate that refined copper strip processes driven by flat copper strip improvements minimize impurities in thin copper strips, improve copper strip roll alignment, and strengthen Horizontal Continuous Casting Copper Strip conformity with global standards.

Industry certifications highlight that strengthened copper strip metallography combined with flat copper strip calibration ensures consistent mechanical performance in thin copper strips, increases copper strip roll reliability, and validates the precision of Horizontal Continuous Casting Copper Strip technology.

OEM evaluations reveal that high-stability copper strip engineering paired with flat copper strip accuracy results in resilient thin copper strips, more predictable copper strip roll winding, and premium-grade Horizontal Continuous Casting Copper Strip production.

Global buyers affirm that premium copper strip quality enhanced by flat copper strip uniformity protects the structural integrity of thin copper strips, maintains copper strip roll consistency, and supports long-term Horizontal Continuous Casting Copper Strip performance.

SECTION 5 – GLOBAL FUTURE OUTLOOK

Forecasts indicate that demand for advanced copper strip solutions working in harmony with flat copper strip technology will continue rising as industries rely more heavily on high-precision thin copper strips, durable copper strip roll materials, and trusted Horizontal Continuous Casting Copper Strip systems.

Strategic assessments suggest that companies expecting long-term growth are increasingly adopting copper strip innovations supported by flat copper strip mechanization to boost the quality of thin copper strips, enhance copper strip roll logistics, and secure Horizontal Continuous Casting Copper Strip reliability.

Long-term projections indicate that automated copper strip platforms integrating flat copper strip optimization will dominate production of thin copper strips, expand the global use of copper strip roll formats, and cement the industry leadership of Horizontal Continuous Casting Copper Strip technologies.

Economic forecasts highlight that next-generation copper strip capabilities built around flat copper strip refinement will support flexible thin copper strips, strengthen copper strip roll export potential, and accelerate adoption of Horizontal Continuous Casting Copper Strip manufacturing.

Analysts predict that global markets will reward copper strip producers who invest in flat copper strip precision, enabling superior thin copper strips, stronger copper strip roll packaging, and more competitive Horizontal Continuous Casting Copper Strip performance.

Industry leaders conclude that the future belongs to copper strip manufacturers adopting advanced flat copper strip workflows that ensure optimal thin copper strips, stable copper strip roll processing, and sustainable Horizontal Continuous Casting Copper Strip development worldwide.