Why Does the Drawing Machine Play a Key Role in Metal Processing?

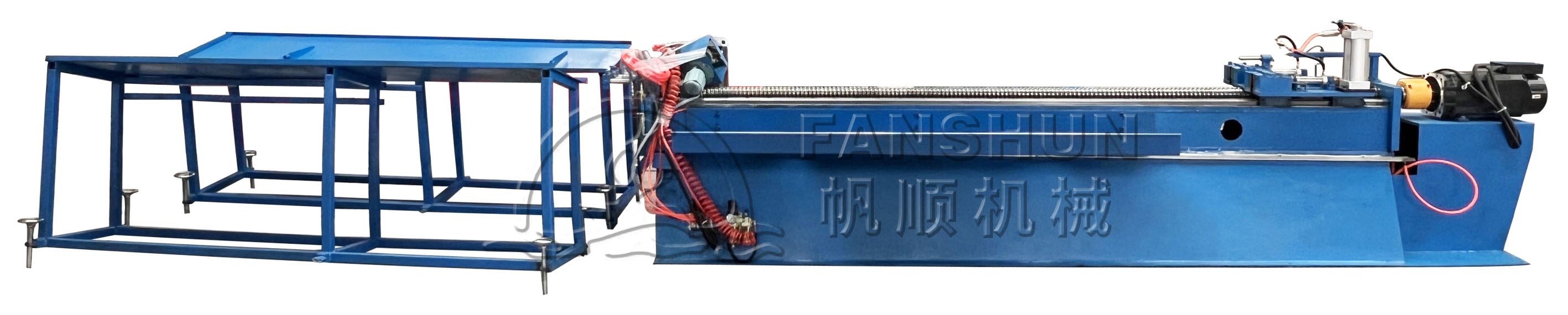

In the ever-evolving world of metal processing, the Drawing Machine has emerged as an indispensable tool. This equipment, designed to reshape and refine various metal materials, plays a pivotal role in ensuring precision, quality, and efficiency in manufacturing processes. The versatility and adaptability of the Drawing Machine, along with its specialized variants such as the Hydraulic Drawing Machine, Cold Drawing Machine, Bar Drawing Machine, and Rod Drawing Machine, have made it a cornerstone of the metalworking industry.

The Functionality of the Drawing Machine

At its core, the Drawing Machine works by pulling metal materials through a die, reducing their cross-section while increasing their length. This process not only enhances the material's physical properties but also ensures a uniform and smooth finish. The ability to control dimensions and surface quality makes the Drawing Machine essential for producing metal components that meet stringent industrial standards.

Specialized Variants of Drawing Machines

Hydraulic Drawing Machine:

The Hydraulic Drawing Machine uses hydraulic power to pull metals through the die. This variant is particularly suited for heavy-duty operations, handling larger metal pieces with ease. Its precise control and immense pulling force make it ideal for processing thick metal rods and tubes.Cold Drawing Machine:

Unlike conventional drawing machines, the Cold Drawing Machine operates at room temperature. This cold working process enhances the metal’s strength through strain hardening, making it perfect for industries requiring high-strength materials, such as aerospace and automotive manufacturing.Bar Drawing Machine:

The Bar Drawing Machine specializes in processing metal bars, ensuring they achieve the desired dimensions and surface quality. From round to square and hexagonal bars, this machine provides unparalleled precision and efficiency.Rod Drawing Machine:

Similar to the Bar Drawing Machine, the Rod Drawing Machine focuses on reshaping metal rods. Its adaptability allows it to process various rod materials, including steel, aluminum, and copper, meeting the diverse needs of the metalworking sector.

Key Roles in Metal Processing

Precision and Accuracy:

The Drawing Machine ensures that metal materials are processed with exact dimensions and superior surface quality. This precision is particularly crucial in industries like construction, aerospace, and electronics, where even minor deviations can lead to significant performance issues.Material Strengthening:

Machines like the Cold Drawing Machine improve the mechanical properties of metals by inducing strain hardening. This results in stronger, more durable components that can withstand rigorous operational demands.Versatility in Applications:

From the Hydraulic Drawing Machine for heavy-duty operations to the Rod Drawing Machine for processing smaller components, the Drawing Machine family caters to a wide range of industrial needs.Cost-Efficiency:

By reducing material waste and optimizing processing times, the Drawing Machine helps manufacturers achieve cost savings while maintaining high-quality output.

Industry Applications

The Drawing Machine, along with its specialized variants, finds applications in various industries:

Automotive: Producing precision components such as axles and shafts.

Construction: Shaping metal bars and rods for structural applications.

Electrical: Manufacturing conductive rods and wires.

Aerospace: Creating lightweight yet strong components through the Cold Drawing Machine.

The Future of Drawing Machines

With advancements in technology, the Drawing Machine continues to evolve. Modern machines, such as the Hydraulic Drawing Machine, are now equipped with automation and digital control systems, enabling higher precision and efficiency. The demand for sustainable and eco-friendly processes has also led to innovations in the Cold Drawing Machine, reducing energy consumption while maintaining performance.

Customer Feedback and Market Insights

Manufacturers using the Drawing Machine family have consistently reported enhanced productivity, reduced operational costs, and superior product quality. Whether it’s the Bar Drawing Machine for reshaping bars or the Rod Drawing Machine for refining rods, these machines have proven their worth across various sectors.

Conclusion

The Drawing Machine, with its specialized variants like the Hydraulic Drawing Machine, Cold Drawing Machine, Bar Drawing Machine, and Rod Drawing Machine, plays a key role in metal processing. Its ability to deliver precision, improve material properties, and adapt to diverse industrial needs makes it a vital asset for manufacturers. As the industry continues to progress, the Drawing Machine will remain at the forefront, driving innovation and efficiency in metalworking.