Why Is the Anode Plate Production Line So Important for Copper Refining?

The copper anode plate is a cornerstone of modern Electrolytic Refining processes. Every efficient copper refinery relies on a well-designed Anode Plate Casting Line and a high-performance Anode Casting Furnace to transform scrap copper into high-purity copper products. The role of the copper anode plate cannot be overstated, as it directly influences the quality, efficiency, and sustainability of Electrolytic Refining.

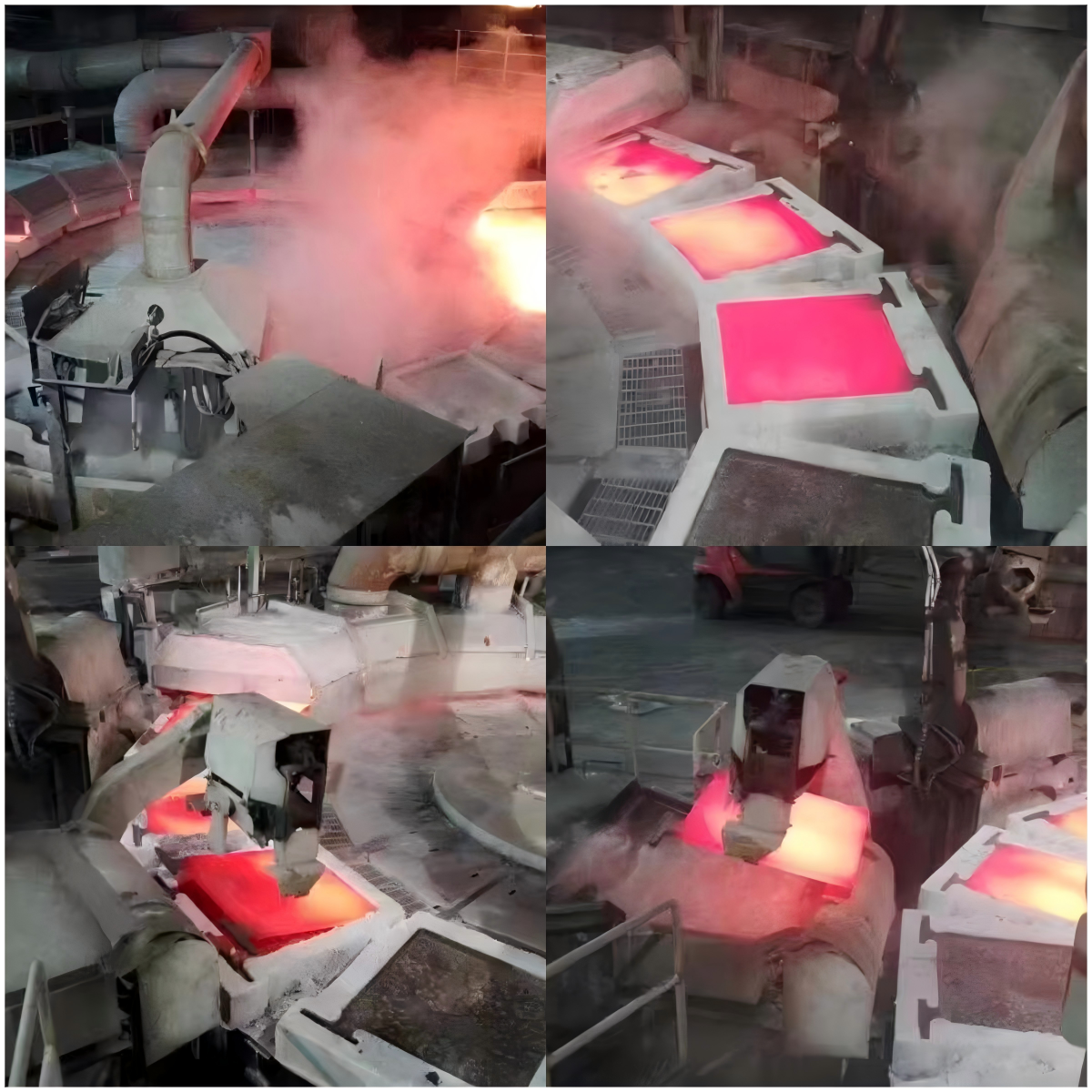

In a typical copper refinery, scrap copper serves as the raw material that feeds into the Anode Casting Furnace. Through controlled melting in the Anode Casting Furnace, the scrap copper is converted into molten copper, which is then shaped into copper anode plates via the Anode Plate Casting Line. Each copper anode plate produced must meet precise specifications to ensure optimal performance during Electrolytic Refining.

The Anode Plate Casting Line is specifically engineered to produce copper anode plates consistently from scrap copper. With a modern Anode Casting Furnace, refineries can melt scrap copper efficiently, controlling temperature and composition to achieve superior copper anode plate quality. The precision of the Anode Plate Casting Line ensures that each copper anode plate is uniform, free from impurities, and suitable for Electrolytic Refining.

Using scrap copper as a feedstock is both economically and environmentally advantageous. The Anode Casting Furnace converts scrap copper into molten metal efficiently, reducing waste and enabling the production of high-quality copper anode plates. Once cast on the Anode Plate Casting Line, these copper anode plates are ready for the Electrolytic Refining process, where they dissolve to deposit pure copper onto cathodes. Without a reliable Anode Plate Casting Line, the conversion of scrap copper into premium copper anode plates would be inconsistent, affecting the yield and quality of Electrolytic Refining.

The synergy between the Anode Casting Furnace and the Anode Plate Casting Line is crucial. The Anode Casting Furnace ensures that scrap copper melts uniformly, while the Anode Plate Casting Line forms copper anode plates with exact dimensions and purity. These copper anode plates are then transported to Electrolytic Refining tanks, where the controlled dissolution of copper allows for the recovery of ultra-pure copper.

Modern copper anode plate production prioritizes efficiency, precision, and environmental compliance. By utilizing scrap copper in combination with advanced Anode Casting Furnace technology, refineries reduce energy consumption while maximizing the quality of copper anode plates. The Anode Plate Casting Line automates many aspects of production, ensuring that every copper anode plate meets strict tolerances necessary for successful Electrolytic Refining.

The process begins with collecting high-grade scrap copper, which is sorted and fed into the Anode Casting Furnace. The furnace melts the scrap copper, carefully controlling temperature to prevent oxidation and maintain composition. Molten copper is then transferred to the Anode Plate Casting Line, where continuous casting produces copper anode plates with precise thickness and dimensions. These copper anode plates are essential for Electrolytic Refining, as their quality determines the efficiency of copper deposition and the purity of the final product.

One of the most important considerations in producing copper anode plates is the type of scrap copper used. High-quality scrap copper ensures minimal impurities, allowing the Anode Casting Furnace to produce molten copper suitable for forming copper anode plates. The Anode Plate Casting Line then shapes the molten copper into plates that meet the strict chemical and physical requirements of Electrolytic Refining. The integration of scrap copper, Anode Casting Furnace, and Anode Plate Casting Line guarantees consistent production of copper anode plates, which are vital for the economic and technical success of Electrolytic Refining.

Refineries worldwide rely on the combination of scrap copper, Anode Casting Furnace, and Anode Plate Casting Line to maintain production efficiency. Each copper anode plate produced undergoes rigorous inspection to ensure it meets purity standards before entering Electrolytic Refining tanks. The high density of copper anode plates ensures a stable dissolution rate, which is critical for consistent copper deposition during Electrolytic Refining.

Using scrap copper as a feedstock for copper anode plates not only reduces production costs but also supports sustainable manufacturing. The Anode Casting Furnace maximizes energy efficiency while melting scrap copper, and the Anode Plate Casting Line ensures that copper anode plates are uniform and defect-free. These innovations in the Anode Casting Furnace and Anode Plate Casting Line directly impact the quality and yield of Electrolytic Refining, making copper anode plate production indispensable for modern copper refineries.

In summary, the Anode Plate Casting Line and Anode Casting Furnace are critical in converting scrap copper into high-quality copper anode plates, which are the backbone of Electrolytic Refining. Without a reliable production line, the efficiency and purity of copper anode plates would be compromised, affecting the entire refining process. By optimizing scrap copper processing and utilizing advanced Anode Plate Casting Line technologies, refineries can ensure consistent production of copper anode plates, supporting sustainable and efficient Electrolytic Refining practices.