The copper plate price is influenced by various factors, including the availability of raw materials and the efficiency of production processes. The copper plate price fluctuates based on market demand and production costs. The demand for pure copper plates remains high across industries due to their exceptional conductivity and corrosion resistance.Manufacturers often rely on Scrap furnaces to recycle copper scrap and minimize production costs. In the production line, small copper plates are produced using a Medium frequency furnace continuous casting machine, ensuring precision and consistency in casting. Pure copper plates are highly sought after for their superior conductivity and durability. Scrap furnaces are integral to the recycling process, where copper scrap is melted down to create new materials, contributing to sustainability efforts. Small copper plates are efficiently produced using Medium frequency furnace continuous casting machines, ensuring consistent quality and precise dimensions. These machines play a pivotal role in the manufacturing process, allowing for seamless production of copper plates to meet diverse industrial needs. Through the utilization of these key components, manufacturers can maintain competitive prices while delivering high-quality copper products to the market. |

3D Animation Preview

| More information about the 3D animation,please "contact us". |

Production Process

| First, melt and adjust the composition of the copper plate for downward semi-continuous casting. Then, use the semi-continuous casting method to cast the copper billet downwards. Segment the billet through sawing, remove the surface oxide skin by milling, heat for hot rolling, then cold rolling, acid pickling, cold rolling again, cutting into strips, and finally, packaging the finished product. |

Equipment Configuration Reference

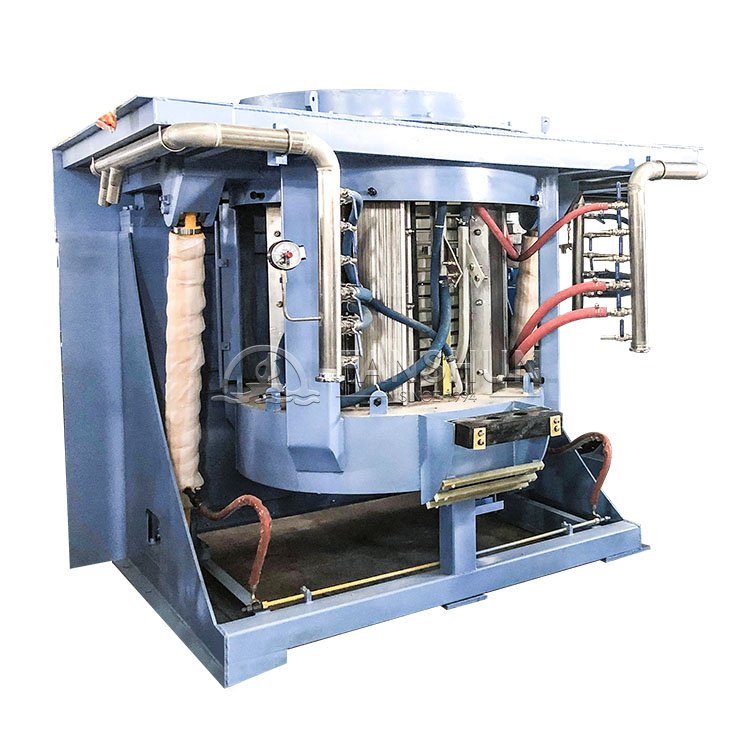

| Industrial Frequency Furnace |

| Downward Semi-Continuous Caster |

| The continuous casting machine for downward semi-continuous casting with copper molds. |

| Environmental Protection Equipment |

| Surface Milling Machine |

| Heating Machine |

| Hot Rolling Mill |

| Cold Rolling Mill |

| Cleaning Production Line |

| The semi-continuous casting billet prior to hot rolling for downward casting |