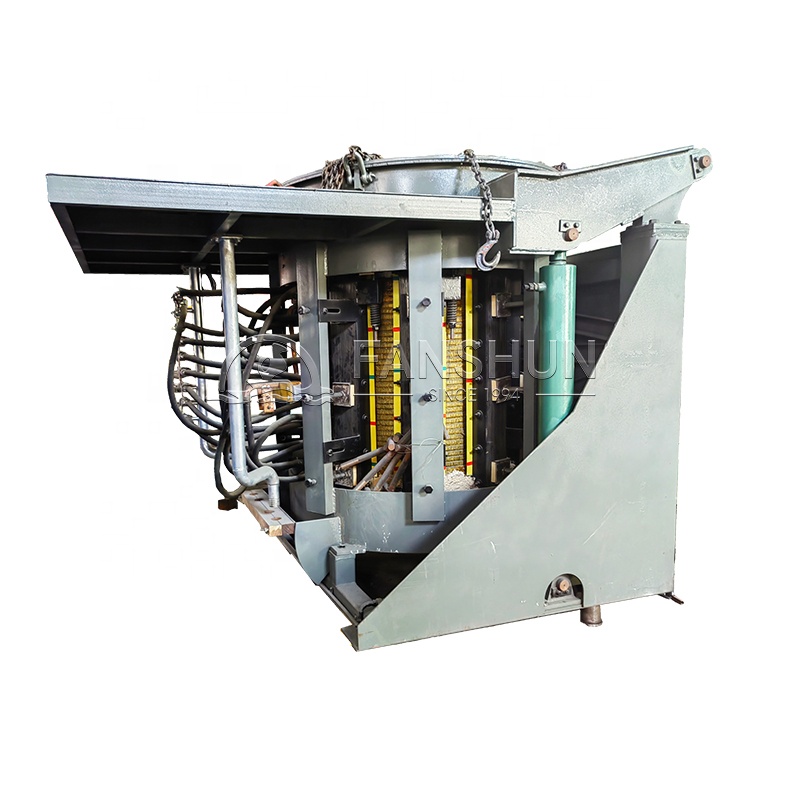

Induction furnace is usually divided into induction heating furnace and melting furnace. There are two types of melting furnaces: cored induction furnaces and coreless induction furnaces. Core induction furnace has iron core through the inductor, power frequency power supply, mainly used for all kinds of metal melting and insulation, electrical efficiency of more than 90%, can use waste, low smelting cost. Coreless induction furnace has no iron core through the inductor, divided into power frequency induction furnace, triple frequency induction furnace, etc. The advantage of this type of coreless induction power frequency furnace is that the loss of raw materials is much less than other equipment, and it has very little smoke, low thermal divergence, less environmental pollution, so it has low requirements for the production environmen.

Send EmailMore