Why is the Rolling Drawing Bench Increasingly Favored by the Manufacturing Industry?

In the evolving landscape of metal manufacturing, the demand for precision, efficiency, and superior product quality has never been higher. Among various advanced machinery, the Rolling Drawing Bench stands out as a critical tool that has gained increasing favor in the manufacturing industry. This article delves deep into why the Rolling Drawing Bench is becoming indispensable alongside complementary machines like the Metal Rod Drawing Machine, Finishing Machine, Drawing Machine, and Bar Polishing Machine.

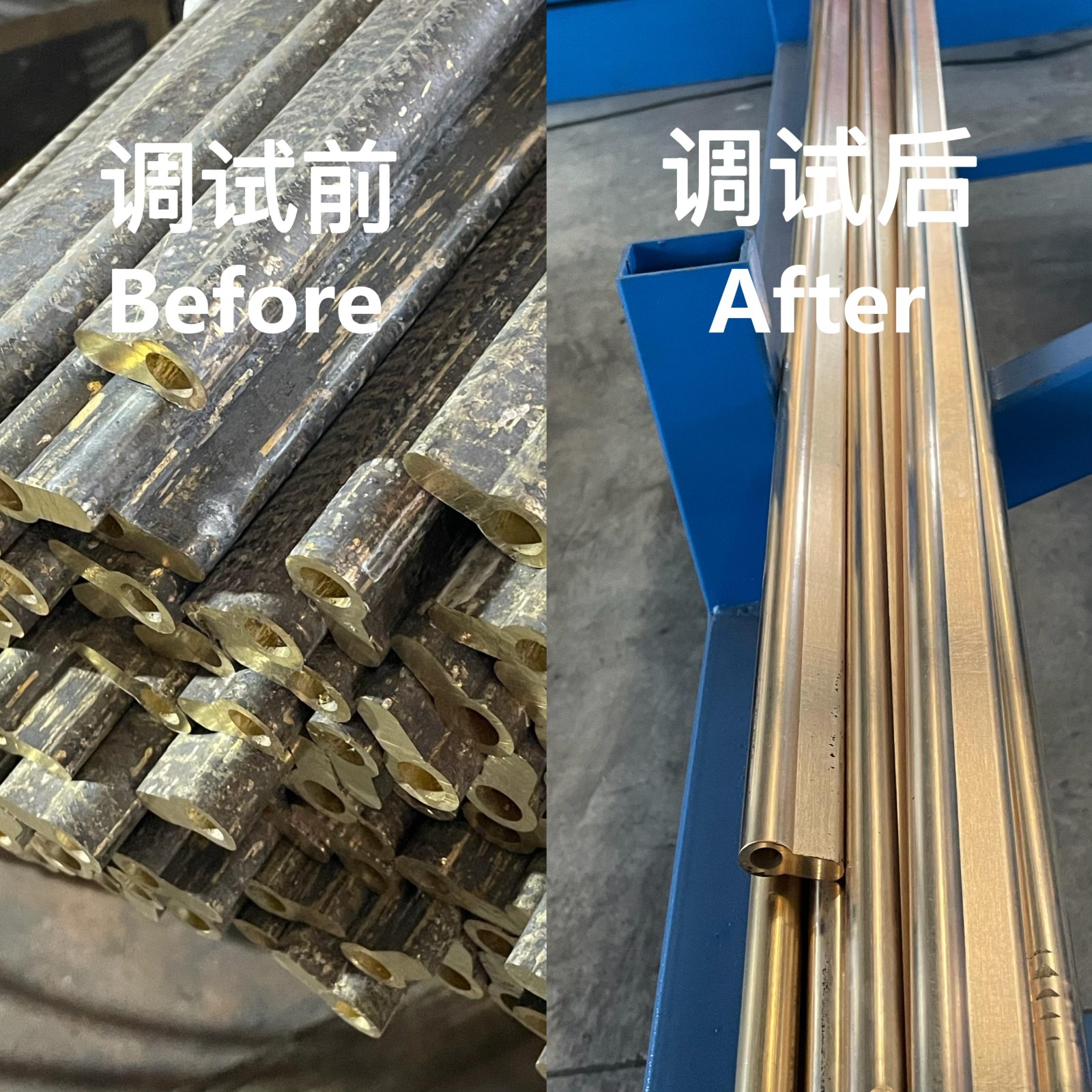

The Rolling Drawing Bench is a specialized form of Drawing Machine engineered to process metal rods by drawing them through rollers. This process enhances surface finish, ensures dimensional accuracy, and improves mechanical properties. Unlike traditional Drawing Machines, the Rolling Drawing Bench offers smoother finishes and greater operational efficiency, making it an essential piece of equipment for modern metalworking factories.

One key reason the Rolling Drawing Bench has gained popularity is its seamless integration with the Metal Rod Drawing Machine. The Metal Rod Drawing Machine is responsible for reducing the diameter of metal rods by pulling them through precise dies. When combined with the Rolling Drawing Bench, the rods not only achieve accurate dimensions but also benefit from enhanced surface texture and consistency. Following these stages, the rods often undergo treatment in a Finishing Machine to remove residual imperfections and prepare the surface for polishing.

The Finishing Machine plays a vital role in the manufacturing line, working in close conjunction with both the Drawing Machine and the Rolling Drawing Bench. While the Drawing Machine performs the essential task of shaping and sizing the rods, the Finishing Machine focuses on refining the surface, removing minor defects, and enhancing the rod’s appearance. This step is crucial before the rods reach the Bar Polishing Machine, which provides the final surface treatment.

The Bar Polishing Machine is indispensable for producing metal rods and bars with a bright, smooth, and corrosion-resistant surface. When used after the Rolling Drawing Bench and Finishing Machine, the Bar Polishing Machine imparts an aesthetic appeal and extends the service life of the products. The combined operation of the Rolling Drawing Bench, Metal Rod Drawing Machine, Finishing Machine, Drawing Machine, and Bar Polishing Machine creates a comprehensive workflow that maximizes product quality and manufacturing efficiency.

Efficiency is a significant factor in the growing preference for the Rolling Drawing Bench. This machine allows for continuous and automated operation, reducing downtime compared to manual or semi-automatic Drawing Machines. Additionally, the Rolling Drawing Bench minimizes human error, improves throughput, and offers consistent product quality. In tandem, the Metal Rod Drawing Machine ensures precise diameter reduction, while the Finishing Machine and Bar Polishing Machine guarantee impeccable surface quality.

Versatility is another advantage of the Rolling Drawing Bench. It is capable of processing various metals and rod sizes, making it adaptable to different manufacturing requirements. Paired with the Metal Rod Drawing Machine, it forms a robust system for producing metal rods with tight tolerances and superior finish. The Finishing Machine further enhances the rods, and the Bar Polishing Machine adds the perfect finishing touch, making this combination highly favored in the metal industry.

Technological advancements have improved the performance and reliability of the Rolling Drawing Bench and its complementary machines. Modern Drawing Machines now offer improved control systems, better die designs, and higher precision. These improvements directly affect the efficiency of the Metal Rod Drawing Machine and the Rolling Drawing Bench, resulting in higher quality outputs. Similarly, Finishing Machines and Bar Polishing Machines have evolved to provide more consistent polishing, reduced processing times, and better surface finishes.

The manufacturing industry’s demand for better surface quality and mechanical properties has accelerated the adoption of integrated production lines featuring the Rolling Drawing Bench, Metal Rod Drawing Machine, Finishing Machine, Drawing Machine, and Bar Polishing Machine. These machines work together to streamline production, reduce waste, and ensure the final product meets exacting standards.

In summary, the increasing favorability of the Rolling Drawing Bench in the manufacturing industry stems from its unmatched ability to improve product precision, operational efficiency, and surface quality. Alongside the Metal Rod Drawing Machine, Finishing Machine, Drawing Machine, and Bar Polishing Machine, it forms a cohesive production system essential for modern metalworking enterprises. Manufacturers aiming to remain competitive and meet evolving market demands continue to invest in these integrated machines, ensuring their production lines are efficient, reliable, and capable of delivering superior metal rods and bars.