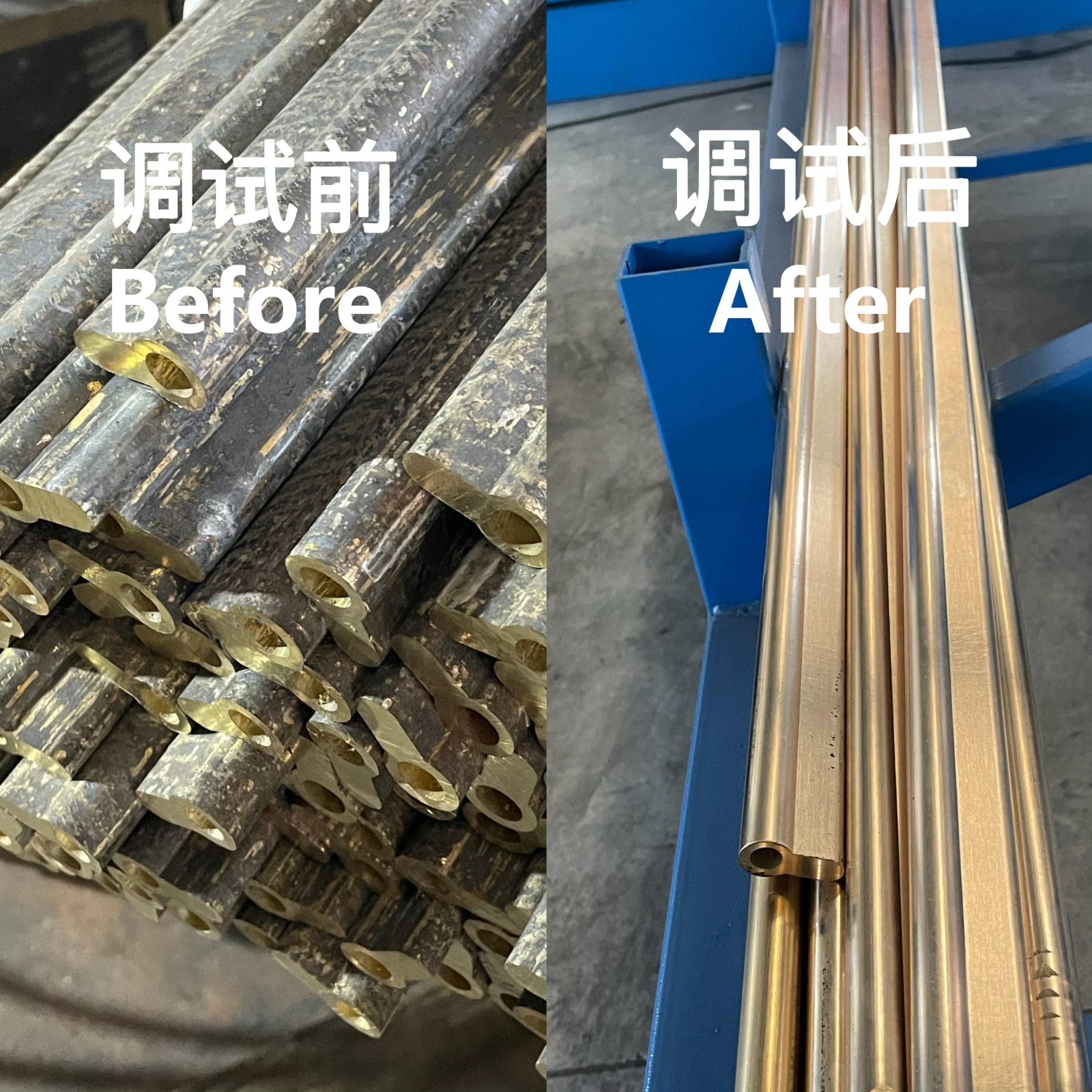

This rolling drawing bench is specially designed for surface finishing of metal rods such as copper and aluminum rods, effectively removing the oxide layer to restore a bright and smooth surface. The machine features multiple sets of upper and lower elastic rollers rotating synchronously in opposite directions, continuously pressing and pulling the rods through a removable mold holder, achieving high-precision surface scraping. The mold holder is detachable to accommodate rods of different shapes. Supporting continuous operation without stopping, this rolling drawing bench significantly improves production efficiency while minimizing material waste, making it a highly efficient, energy-saving, and versatile metal surface treatment solution.

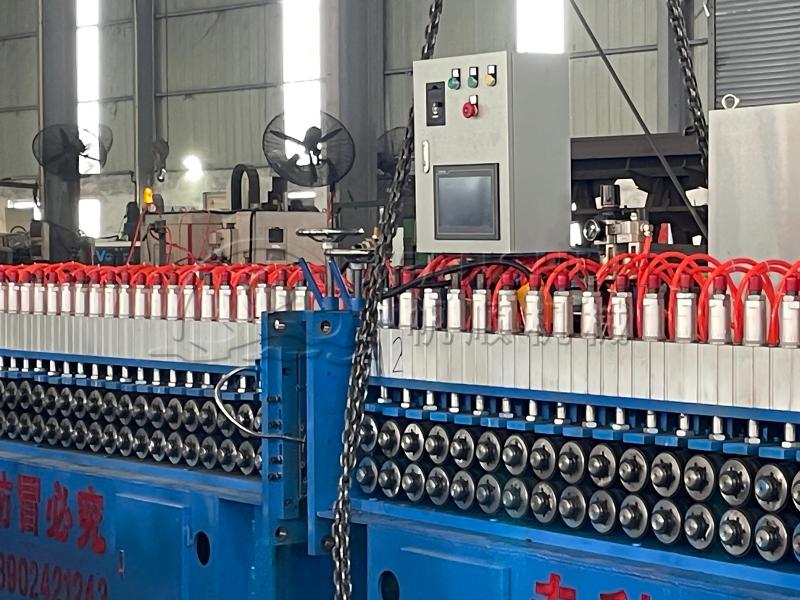

Dual-Section Traction System:

Front and rear sections with gear-driven, oppositely rotating upper and lower elastic rubber rollers provide stable and continuous feeding of metal rods with uniform pressure.

Detachable Mold Holder:

Easily installed at the channel’s inlet and/or outlet, the mold holder allows quick replacement of molds to accommodate various rod shapes and sizes.

Multi-Stage Compression Channel:

Multiple sets of synchronized elastic rollers create a consistent compression path, ensuring precise removal of oxide layers and smooth surface finishing.

Precision Adjustment Mechanism:

Equipped with a screw lifter and dual hydraulic cylinders for accurate vertical positioning and pressure control of roller assemblies, enabling flexible operation.

Continuous Operation & Material Saving:

Designed for nonstop processing, significantly improving production efficiency while minimizing material waste and preventing rod damage.

| Name | Specification | Quantity | |

Rolling Drawing Bench 4-Meter Model (4 Sets) | Rubber Pressure Rollers | 288 | |

100×75 Cylinder Adjustable to 55 | 144 | ||

| PLC Control System | 1 Set | ||

| Main Motor | 15KW | 4 | |

Gearbox | 400 Box 1:15.75 Triple Assembly | 4 | |

| Unloading Machine | 1 Unit | ||

| Feeding Machine | 1 Unit | ||

| Discharge Feeder | 3 Units |

Copper rods, brass rods

Aluminum rods, aluminum alloy bars

Stainless steel rods, alloy bars

Round bars, hexagonal bars, special-shaped bars (customizable)

Clean the rubber wheel surfaces daily to remove debris and inspect for wear/deformation, ensuring stable pressure in the hydraulic and lifting systems. Periodically disassemble the mold base to clear residues, and promptly repair or replace worn molds to maintain scraping precision. Lubricate gear transmission components and guide rails on schedule, and test emergency stop safety functions. The core objectives are to sustain consistent rubber wheel clamping force and sharp mold edges, enabling continuous and efficient oxide removal while minimizing material waste.