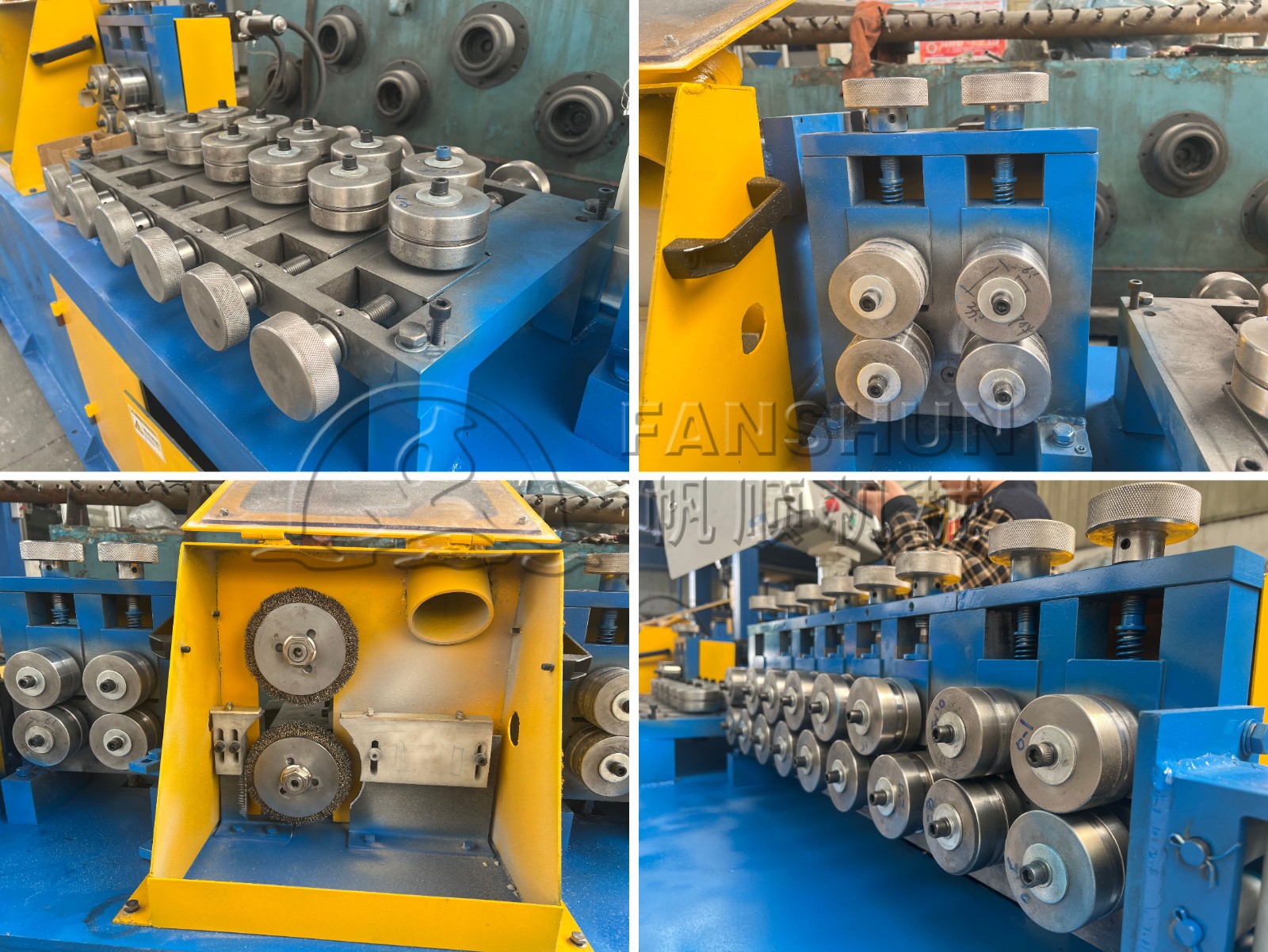

Detailed images

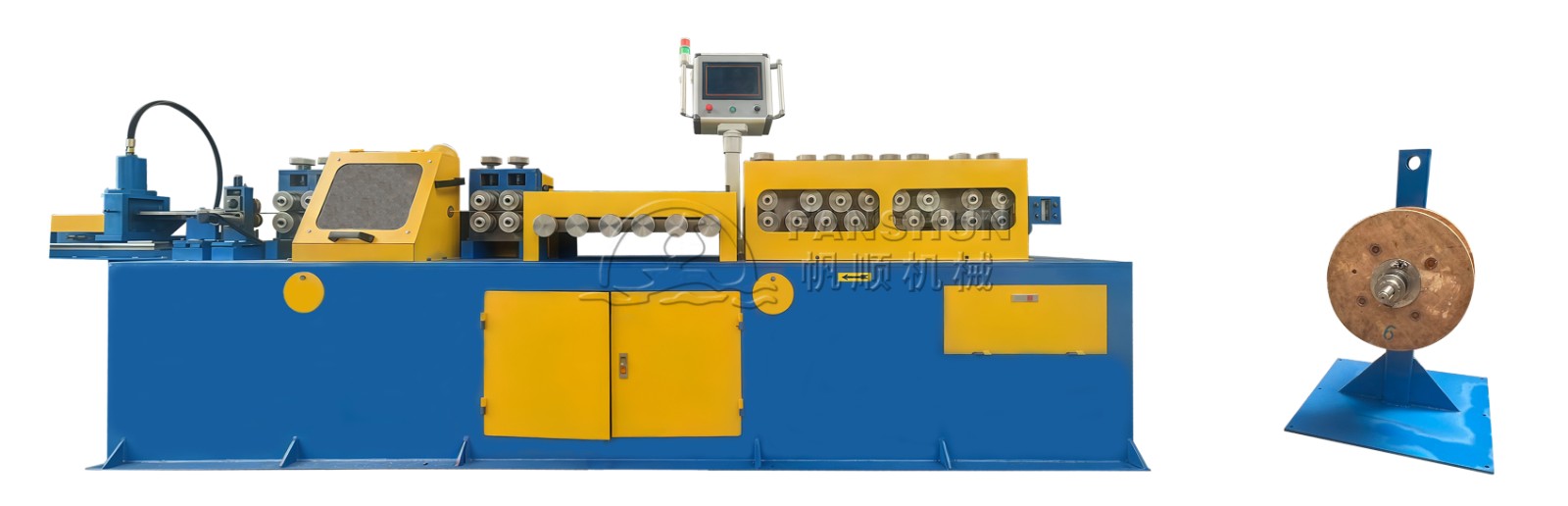

Straightening, grinding and shearing machine

I. Product Description

This machine is suitable for stainless steel, iron, copper, aluminum and other metal round wire, shaped wire, flat wire, straightening, continuous grinding and automatic cutting off according to the customer's demanded length. Widely used in hardware processing, electrical industry, home appliances, furniture, stainless steel manufacturing and other industries.

II. Features

Straightening and cutting in one operation:

The machine performs coarse straightening, fine straightening, grinding and continuous automatic cutting according to the required length, all in one machine.

High degree of automation:

It reduces the labor intensity of workers. The whole machine is controlled by PLC programmer, and the straightening speed and cutting length are adjustable respectively. In the case of straightening without stopping, it automatically cuts according to the required length.

High degree of digitalization:

Easy to adjust, good precision and high efficiency. It is highly praised by our customers.

III. Technical Parameters

| Input Voltage | 380V(Three-phase 4 wires) |

| Frequency | 50HZ |

| Total Power | 15.3KW |

| Straightening Diameter | less than ¢8mm 12 * 3 mm |

| Straightening Accuracy | less than 2mm/M |

| Maxium Straightenning Speed | 80mm/minutes |

| Maxium Shear Strength | 350MPa |

| Minimum Shear Length | more than 0.5m |

| Shear Accuracy | less than 2mm |

| Maximum Output Pressure of Hydraulic Station | 12MPa |

| Outer Dimensions of the Whole Machine | 4650mm*1000mm*1350mm |

| Length of receiving platform | 1000mm*600mm*700mm |

| Length of sanding | 50mm-500mm(reconcilable) |

| Sanded thickness | 0.2mm-0.5mm(reconcilable) |

| Grinding wheel moves up and down | 5-20mm(wear adjustment) |

| Maximum shear length | 10m(according to the receiving platform) |

| Weight | 2000Kg |

IV. Selection Recommendations

Based on Production Volume:

Small-scale production (prototyping/low volume):Choose semi-automatic machines with manual feeding (capacity: 0.5~2 tons/day).

Medium-scale production (batch processing):Choose automated machines with servo feeding (capacity: 2~10 tons/day).

Large-scale production (continuous processing):

Choose fully integrated CNC lines with conveyor systems (capacity: 10~50 tons/day).

Based on Material Specifications:

Thin copper flat wire (0.1~2mm thickness):Choose machines with low-pressure rollers to avoid deformation.

Thick copper flat wire (2~6mm thickness):Choose machines with high-torque straightening & heavy-duty shearing.

V. Maintenance and Care

Regularly inspect straightening rollers: Ensure the roller surfaces are free from wear to prevent scratches on the copper flat wire.

Clean copper debris promptly: Remove accumulated copper scraps daily to maintain machining accuracy.

Keep cutting blades sharp: Periodically check blade edges to ensure clean, burr-free cuts.

Calibrate machine precision: Monthly verification of straightening and cutting accuracy to guarantee product quality.